At present, technologies and means, methods and assemblies, due to which wastewater treatment from oil products is implemented, are among the most important means of ensuring environmental protection. In our country, for about five years now, legislatively established standards for the purification of liquid discharged by enterprises have been in force. The documentation devoted to this issue establishes the quality and volume of water that industrial facilities can produce.

About wastewater

Before considering what should be the treatment of wastewater from petroleum products, an understanding of the terminology should be clarified. According to current standards, rainwater, drainage, floor washing liquid, and infiltration are ranked as sewage. Laws regulating the activities of enterprises establish how and how much, when to pay for environmental damage caused by the work of the company. The company must also compensate for the negative impact of harmful compounds, which are rich in discharged water. Centralized sewers are forced to cope with this effect.

Standards were adopted to tighten control over the accounting of water discharged by the enterprise into the environment. Laws have been enacted to regulate the aggressive load of the discharged liquid and oblige to reduce the concentration of harmful chemical compounds. Collection and purification of liquids from oil refined products is a multi-stage procedure. In each individual case, it is necessary to form a sequence of measures, taking into account the working situation.

About factors

When developing a system for treating wastewater from petroleum products at an enterprise, one must take into account how much industrial wastewater is, how much it needs to be reduced, how actively it should work in terms of reducing the concentration of harmful compounds. At the same time, they remember the standards agreed at the federal level - they regulate the maximum, maximum concentrations of substances. It must also be remembered that some impurities may be of value, so they should first be isolated from the total waste fluid in order to be used again.

One of the tasks of a system for treating wastewater from petroleum products is to use the discharged liquid a second time, if appropriate. To assess the possibility of such use, you must first analyze the nuances of technological processes. It is important to take into account the specifics of the water supply to the enterprise.

Studies have shown that almost always water discharged by an industrial facility has inclusions of oil refined products. This is true for all categories, types of firms, for different industries. Among the polluting elements, kerosene and fuel oil, hydrocarbon compounds that are not identifiable, oils, and various oil impurities are most often identified. Petroleum products are in the form of an emulsion in solution, can dissolve completely, but sometimes they occur in the form of a dense surface film, especially noticeable when liquid enters a reservoir. All substances obtained during the oil refining process are characterized by an increased level of toxicity and are ranked at the international level as the most dangerous compounds falling into the environment with industrial emissions.

Approaches: general information

Various methods are known for treating wastewater from petroleum products. Within one enterprise, different lines can be implemented. The mechanical process involves the use of specialized traps, sand traps. Settling tanks and install systems for filtering the liquid. All these plants are among those providing mechanical cleaning.

Perhaps a comprehensive physical and chemical purification of the liquid. This is implemented through flotation systems. The plants used a variety of chemical compounds. Special aggregates are designed to remove colloidal inclusions. For work, coagulants are used.

Biological wastewater treatment from oil products involves the use of specially designed ponds. Filters have been developed for this method of liquid purification. Aeration tanks were widely used.

Finally, there are methods involving the use of a variety of reagents. Impurities are deposited using specialized inclusions. Cleaning is realized through coagulation and flocculation. Common approaches for processing liquids are ion exchange, filter installation, and flotation.

Current situation

The problem of water purification from oil and oil products in our country is that most enterprises have outdated systems and equipment. The main percentage was built in the last century, approximately in the 50s. Today, such systems still work, but outdated equipment is ineffective, so it is not possible to achieve the required quality of liquid purification. As a result, industrial facilities greatly harm the environment, and enterprises that do not install the latest units violate the laws.

Since purification systems often fail to cope with the increasing volume of liquids provided that the concentration of hazardous compounds increases, the quality of the discharged water is getting worse. To some extent, this is due to an increase in the variety of oil refining products that penetrate into discharged liquids. When the systems were just under construction, the engineers could not predict such a level of pollution, so the plants could not cope with the load. It is necessary to take into account the development of resources of installed systems, which is explained by the long-term operation of facilities without regular improvement of performance.

Can I fix it?

In order for the wastewater treatment apparatus from petroleum products to allow the company to operate efficiently without violating the current legislation, it is necessary to introduce innovative solutions. At the moment, the problem is relevant for a huge percentage of industrial facilities existing in our country. It is important to use the latest methodologies. There are many new approaches to wastewater treatment. These help to more effectively protect the environment from the aggressive influence of civilization. According to experts, the introduction of effective cleaning methods will significantly save companies money. However, the real situation is that updates in many firms are unreasonably slow.

Technical Features: General Information

Modern methods of wastewater treatment from oil products are implemented through the use of specialized systems, which are inherently close to fat traps. It is necessary to choose a specific option, evaluating the features of the chemical composition of the pollution characteristic of a particular object, as well as the percentage of hazardous compounds in the liquid, the level of emulsion. In grease traps, particles of contaminants float due to gravitational force, and water treated in this way is directed to common collectors. Many systems for treating wastewater from petroleum products operate on a similar system.

Relevance of the issue

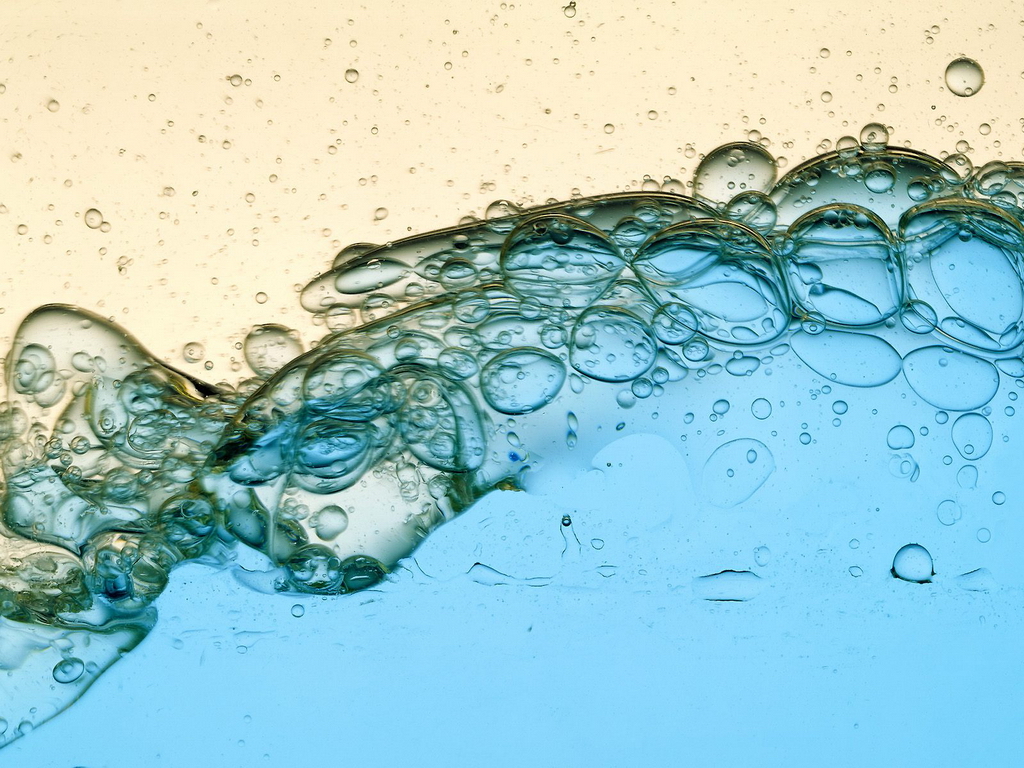

Without the correct use of mechanical, biological wastewater treatment from oil products, without using other approaches, liquid pollution provokes the death of plants and animals. If the enterprise discharges contaminated water, a film or emulsion in the form of drops appears on the mirror surface of the reservoir. Such pollution excludes normal air exchange and harms the ecological status of the territory. Activated sludge cannot develop; natural purification systems cannot function. Oil poisons biocenosis.

The industry of our civilization produces several types of pollution. An impressive percentage of emissions is due to the activity of refineries specializing in oil and oil products. No less dangerous are the transport hubs responsible for the movement of oil, enterprises engaged in the creation of machinery, repair of wagons, and the manufacture of chemical goods. An impressive percentage of pollution is explained by the activity of automobile factories and areas where cars are washed. Any such facility should have local systems to clean the discharged fluid. Their activity helps to reduce environmental pollution. The development of cleaning systems is carried out taking into account storm water from street coverings, roads, drains, machines for melting snow. Storm waters have a relatively low concentration of pollutant ingredients, but the volumes are such that large systems need to be built. The stocks of snow machines are known for the high concentration of petroleum products with a relatively modest amount. There is gasoline in storm drains due to condensation of exhaust gases and oil spills from cars.

Rules and Methods

When choosing methods of wastewater treatment from petroleum products available for a particular enterprise, the requirements for discharged liquid must be taken into account. For example, such can be very harsh so that the water does not interfere with farming and fishing in a pond. Such obligate the use of adsorption purification systems. Activated carbon is used for their arrangement.

We defend the liquid

Oil traps are often used. So called tanks for sedimentation of liquid. This approach is the simplest, classic, but has significant drawbacks. Capacitive sumps take up a lot of space, work with a low level of efficiency. For the liquid to clear, it needs to be provided for several hours. In order for the system to work more efficiently, they install thin-layer modular systems, that is, plate sets located at an angle relative to each other. Due to this internal design, an oil trap for wastewater treatment from oil products operates in a laminar water stream. If turbulence occurs, the efficiency of the process is reduced.

In order for the oil trap, improved by the system of thin-layer modules, to work efficiently from oil products for wastewater treatment, it is necessary to equip it taking into account the coalescence phenomenon. The term refers to the chemical and physical process of enlargement of oil refined products, scattered in volume in the form of small drops, on a hydrophobic surface. When the droplets get larger, they rise to the top layer. The use of such systems with respect to discharges of machines melting snow is especially relevant. To work with melt water to be sufficient, you need to use coagulants. Modular settling is possible in multi-tiered systems with flow distribution mechanisms for the entire installation duration. Thin-layer modules accelerate the process of ascent of droplets, so the volume of aggregates can be slightly reduced.

Oil traps: nuances

In order for the described method of wastewater treatment from oil products to be effective, it is necessary to correctly design the units involved in the working process. In oil traps, structural elements are necessary, thanks to which the sediment will independently crawl to the bottom while raising the emulsion in the upper layer. Important lack of turbulence. Design work is carried out taking into account the dispersed oil composition. If it is necessary to reconstruct an already installed trap, the implementation of a thin-module system should be guided by the standards adopted at the federal level. Reconstructive work, according to experts, will significantly improve the effectiveness of existing systems. For this, coalescence modules need to be introduced. At their expense, the efficiency of cleaning will become greater, while the cost of improving equipment is relatively small.

Flotation

This method of purification of water from petroleum products is called pressure. The method is effective if the contamination in the liquid is not in the form of an emulsion. The workflow involves the use of flocculants, coagulants. During flotation, the liquid is saturated with air. The process occurs with the use of an injector, compressor. Use of installation for aeration by a stream is possible. The required level of saturation is up to 0.6 atmosphere. Then the liquid is directed into the working chamber, where air bubbles form a gas-liquid system. They rise throughout the working volume up. In the process of moving to the gas, the oil refining product sticks, so everything floats together. Next, the upper layer is collected by an oil accumulator.

The ejection flotation method is suitable when it is necessary to remove fatty, oily, oil inclusions. If such a system is used to treat wastewater from oil products, the main pollution with oil and oil ingredients can be removed. Next, the liquid must be sent to the filter for finer processing.

Filtration: details

The main idea of such a process is loading water with subsequent passage through the filter. The liquid moves inside the sorption filtration system from top to bottom or in the opposite direction: this is determined by the characteristics of the load. It may be sand or activated carbon. You can use aluminosilicates or go with special sorbents that trap oil - they are made from polyurethane foam.

The choice in favor of a specific option for the purification of oil from industrial wastewater is determined by the level of contamination of the liquid and the desired outcome. In particular, if the filter works by the adsorption mechanism, if activated carbon is chosen as the load, the cleaning efficiency is estimated at 99.8%. The water that has been treated by this method can be discharged into water bodies where they fish and conduct other activities in a similar sector. When determining the download format, it is important to keep in mind the speed characteristics. Each option has its own optimal density, which provides a good cleaning result. This parameter must be taken into account.

Types and Forms

In order for wastewater treatment from oil products and dyes to be of high quality, it is necessary to take into account the features of the selected method and its technical parameters. The speed of the filtration process depends on the dirt capacity of the selected loading option. Each raw material has its own filtration cycle period. Slow speed allows the fluid to move along the minimum path, which is why a certain percentage of the filter is inactive. At higher speeds, the filtering quality is reduced. Activated carbon is often used - this substance has especially good sorption qualities; but every type of download has advantages and disadvantages. For example, polyurethane foam fillers suffer from the formation of grooves, that is, the liquid does not pass through the entire layer of the used load. The substance has oleophilic qualities, oil and oil products are effectively collected on the inner granular surface. The filtration cycle of such a system is small, and its blocks need to be changed often. To regenerate the load, it is washed and squeezed.

The technological scheme of wastewater treatment from petroleum products using filtration loads obliges to take into account the possible quality level of liquid treatment. For example, when choosing a polyurethane foam filler, a possible concentration level of oil transformation products is up to 15 mg / l. The parameter is explained by the solubility of products derived from oil, water. To obtain wastewater in which the amount of pollutants would not exceed 0.05 mg / l, activated carbon should be used. Only such an adsorption filtration system will give such a high-quality result.

Bio-treatment

The costs associated with the biological treatment of wastewater from petroleum products are a relatively small price in comparison with the benefits that they bring to the environment. The approaches associated with these methods have been actively developed and improved in recent years. , . – . , . , .

– . . , . . . . , – , , , .

, , . . . – 20-30 . , , .

– . 6,5-7,5. . , . , .

– , . , , . , , . , .

The biological system is somewhat different from the filtration mechanical treatment of wastewater from oil products described above. There are options for systems in which the conditions are as close to natural as possible, there are aggregates where the environment is artificially formed. The first type is facilities where the liquid is filtered by soil, water bodies with a flow of water. Air provides the liquid with oxygen, which is necessary for the existence of microscopic life forms. In an artificial setting, breathing is realized through diffusion of oxygen molecules by re-aeration or mechaeration.

More effective than mechanical wastewater treatment from oil products, biological, designed in artificial conditions, requires a biological filter, aeration. An alternative design is aerotanks. Such conditions of the working process provide a relatively high intensity of the ongoing reactions by optimizing the living conditions of bacteria. Biological chemical cleaning in the factory is often implemented by filters, aeration tanks, ponds created specifically for this facility.

To summarize

Wastewater treatment from oil products by flask, microbes, activated carbon and other means, methods and methods is an urgent problem of modern industry. To ensure the safety of life on our planet, all plants and other facilities where oil products are generated and allocated to the outside world must have at their disposal highly efficient cleaning systems. The company is obliged to make a choice in favor of a specific option, taking into account the characteristics of the product polluting the liquid, its concentration. It is important to remember the laws that regulate at the federal level how clean the discharge water should be.