Naturally, the operation of a device leads to the fact that it gradually fails. Some parts break, grease dries, etc. All this applies to hydraulic carts, the repair of which is quite simple, but you need to know how to carry it out and when.

General information

A hydraulic trolley, rokla, deadhead, forklift truck are all the names of the same storage device. Despite the fact that this device is very simple, it still breaks, especially if you operate it with violations. As practice shows, subject to careful handling, the life of the jar is about 5-8 years. After this period, it is imperative to start repairing the hydraulic trolley. Of course, the manufacturer’s warranty will be much less than 5-8 years. Most often, this period is 1-2 years, depending on the confidence of the manufacturer in his product. However, even such a period, the device may not serve if handled carelessly.

Cart Rules

In order to move as far as possible the moment when it is necessary to repair the hydraulic trolley, you need to know the rules for its operation.

- The first and fairly obvious is the careful handling of equipment.

- An important detail that many underestimate is instruction. It is necessary to familiarize yourself with it immediately after buying a jar. Outwardly, they are almost identical, but there is a difference in details, non-observance of which can lead not only to equipment breakdown, but also to injury.

- Despite the fact that the cart is designed to transport goods, it must be loaded wisely. It is completely impossible to overload such a device, but it is necessary to download as follows. For example, if according to passport data the unit is designed for a maximum weight of 1.5 tons, then it is better not to load more than 1-1.2 tons.

- A very important point will be the distribution of cargo over the area of the forks. In order to delay the repair of the hydraulic trolley to the maximum, it is important to ensure that the maximum pressure from the load falls approximately in the middle of the device. If the ends of the forks are overloaded too much, effects such as bends, cracks, etc., can occur quickly.

Service trolleys

Maintenance of this equipment is quite simple, since the design itself is not too complicated. But it is worth noting that this is a very important part in terms of caring for the cart.

- Health Check. This is possible and needs to be checked every day before starting work, as well as after their completion. Inspect the device for performance of all its mechanical components, for the absence of cracks and other defects, for the absence of debris in the wheel part, etc.

- Lubrication. In order to avoid frequent repairs to the hydraulic trolley, the muck must be lubricated. This operation needs to be done once a month. Most often, the nodes that need to be processed are bearings, pistons. If there are any additional nodes, they will be indicated in the technical documentation.

Design and faults

It is important to understand that the design of this equipment is very simple, and therefore the chance of breakage with careful use is small. The main components are: base frame, support wheels and rollers, a pair of forks, a hydraulic unit and its lever handle. Because of its simplicity, it is considered quite reliable.

Here I would like to note that the number of companies that provide services for the repair of hydraulic bogies in Moscow, for example, is quite large. And this suggests that many neglect the rules for handling equipment.

Almost all the malfunctions of such equipment are associated with one node - forklift trucks. By the extent of the malfunction, the problem is most often divided into three groups. Repair and its cost will depend on the one to which group the breakage of a certain junk will belong.

First category

The first group includes the simplest repair of hydraulic bogies, the device of which was not too badly damaged. It is called cosmetic. Most often, this type of work is understood as the simplest maintenance service, which includes the correction of the smallest flaws in the work, as well as the replacement of those parts that have become unusable due to natural wear during operation. Such small details include, for example, rollers and steering wheels with integrated bearings.

The process of replacing them is itself considered the simplest. The only thing you need to know for sure is which material they must be made of in order to be suitable for the normal operation of the cart. Doing the repair of the hydraulic trolley with your own hands is quite realistic, if the breakdown belongs to this category, you only need to know which wheels to put.

Wheel replacement

When replacing wheels, consider the flooring in the warehouse. If it is even and clean, then nylon wheels and rollers are allowed. The advantage of these elements will be a quiet and soft ride. Otherwise, if the floor is rather rough and uneven, it is best to purchase wheels made of polyurethane or rubberized metal. A big plus of these details will be a high rate of endurance. However, even when installing such wheelsets or rollers, it is best to ensure that at least minimum cleanliness is maintained in the warehouse and that the most broken sections of the floor are repaired. This one-time operation can be much cheaper than a constant change of wheelset.

In addition to this operation, operations such as cleaning, lubricating, tinting scratches, changing the oil in the hydraulic unit can be attributed to the first category. Repair of a jar (hydraulic cart) at this stage is quite cheap, but very important, since its timely implementation can greatly extend the life of the equipment and delay the occurrence of more serious breakdowns.

Second group

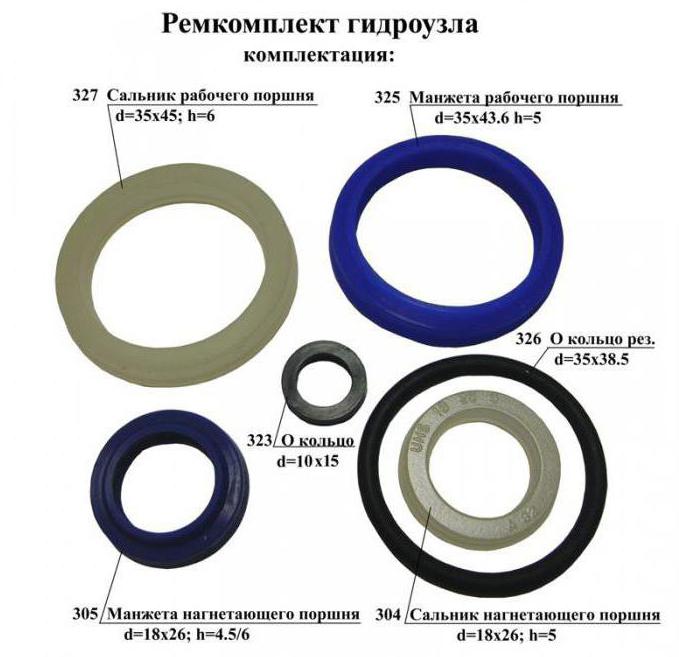

The second group includes full repair of the cart. The provision of services for the correction of defects from this category is the most popular. Faults related to this group are breakdowns of the hydraulic lever-lever. This element most often fails due to careless handling. Most often, as a repair, it is necessary to replace the entire handle, its spring or the step lever. The second most frequent failure is the failure of the hydraulic system itself. As a repair in this case, it is necessary to change the seals and valves or the entire housing assembly. It is important to note here that repairing this complexity with your own hands is no longer considered reasonable. For this reason, if the equipment makes a creak, it is difficult to rise or fall, or gives any other signs of breakage, you should immediately contact a service center.

In order to avoid breakdowns in the hydraulic system, it is necessary that the operator completely lowers and completely lifts the cart. In this position, the pressure of the load on the system will be minimal.

Faults and repair of hydraulic carts of the third group

This category already refers to overhaul. Naturally, it is considered the most complex and expensive. In this case, it would be advisable to first calculate the repair costs, then take the assembly date into account and think that if the equipment is old and the repair cost is more than 50-60% of the initial price, it is better to just buy new equipment.

If repair is necessary, then it can be of two types. The first type is a comprehensive work, the essence of which is the replacement of almost all the nodes of the cart. The second type is directed repair. In this case, most attention is paid to eliminating mechanical problems. Such breakdowns include severe cracks, kinks, bent parts, etc. It is also important to consider that after a major mechanical or complex repair, no service center will guarantee that the cart will be as durable as after leaving the factory. You will have to observe many restrictions during the operation of the device.