The art of heat treatment of metals has been known to mankind for a long time. They were masters involved in the manufacture of tools, and in particular weapons, mastered on their own, or studied for many years with other specialists, more experienced. Secrets were kept secret, which, of course, reduced the speed of technology distribution, but increased the competitiveness of a specific manufacturer of products for a specific purpose. One of the techniques of medieval gunsmiths was surface hardening, which gives the cutting edges and the edges of swords and sabers a special hardness combined with the flexibility of the blade. Today, it’s not surprising anyone with such properties, the technologies have become widespread and have become widespread.

Why does an ordinary person know all this?

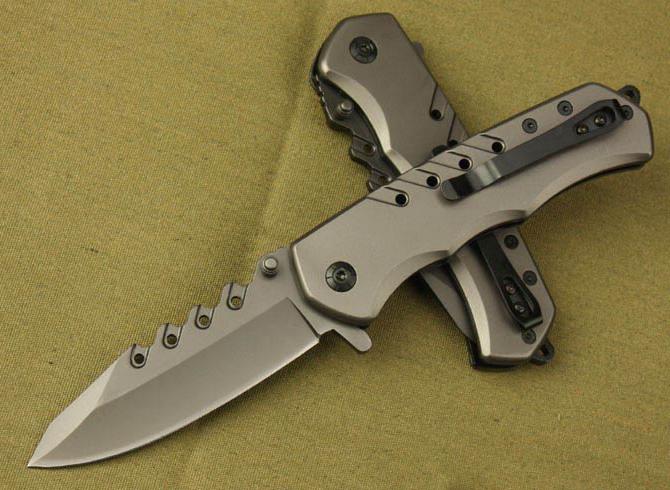

This article seems to specialists in thermal metalworking, most likely, a set of commonplace and well-known facts. In addition, they may find some inaccuracies in terminology. The information presented is not intended for them, it is addressed to people far from metallurgy, amateurs who are interested in how a regular table or folding knife differs in strength from a good blade, surface hardening from volumetric and the like. Buying one or another item needed in the household, the consumer is faced with a significant price difference. The seller can not always explain in a qualified and understandable way why one tool (wrench, for example) is much more expensive than another with general external similarity. Most likely, he will try to “dust his brains” with concepts and terms that are obscure to the average layman. Translated into ordinary language, these explanations will mean that the adjustable wrench will not break or last longer, and sharpening will be required much less often (if the client wants to buy a knife). “Surface hardening!” - the seller mysteriously indicates the reason, rolling his eyes in imaginary delight. What is it?

Opposite properties in one product

As is clear from the phrase, in this case only the outer thin layer of the product is subjected to heat treatment. The fact that steel requires hardening is vaguely guessed by everyone, even those who do not know what it is at all. That is what it differs from the usual "piece of iron", soft and brittle. But why is the superficial one used such honor? Hardening is used to change the properties of the metal, and not for the sake of any improvement, as is often stated. Quality, useful in some cases, becomes harmful in others. The file is hard, therefore it is easy for them to process iron, aluminum or bronze, but if you try to bend it or hit it with a hammer, then it will crack. The same applies to the hacksaw blade, often breaking at the wrong angle of cut. In order to give hardness in combination with flexibility or ductility, surface hardening is used. After it, the properties of the product can combine qualities, sometimes opposite, characteristic of different crystalline structures. Now you need to delve into some material science details.

The simplest concepts of the polymorphism of metals

The same metal can, depending on the shape of the crystal lattice, have different physical properties (hardness, toughness, ductility, flexibility, elasticity, etc.) This ability to change mechanical parameters is called polymorphism. For a long time, making primitive weapons, people noticed that a particular sword or cleaver turned out to be more successful, it remains sharp for longer and does not break. Of course, our ancestors were not familiar with the molecular structures of the metal, they came to everything intuitively and empirically. So, experimentally, they discovered that if the tip is heated, then its temperature depends on the shades of the glow. With rapid cooling, something changes in the metal, it either becomes harder or acquires flexibility. If it is reheated, it again becomes as it was, and sometimes worse. By that time, quite specific ideas had formed about what an ideal hunting knife should be, for example . Surface hardening was also used already then, but the so-called local one was used more often, that is, one with a hard point, flexible - the middle of the blade, and the part of the blade adjacent to the handle - plastic (it is better to bend a little, but not break).

What's going on inside

Without going into particular details, it should be noted that the structure of hardened steel is of three main types: martensitic, troostitic and sorbitol. The mechanical characteristics also depend on the ratio of these crystalline formations. In this case, it does not matter which one and how it affects the hardness. The result depends on how hot the metal is and how quickly it is cooled. Thus, surface hardening can occur with increasing temperature of the upper layer and subsequent cooling either as a result of heat transfer to the external environment (liquid, most often oil, water and brine, air or other agents), or due to its partial withdrawal into the product. In this case, polymorphic transformations occur in layers, depending on the degree of achievement of the critical temperature, which affects the formation of a new crystalline structure.

As a result, a change occurs in the following zones:

- Upper hardened.

- Intermediate, partially hardened. It is also called the zone of thermal influence.

- Area of reduced hardness.

- The interior, not subject to change.

Surface hardening methods

There are several ways to create a top layer with increased hardness. Railway wagon spring springs are simply fired at with small metal balls (shots) that create surface compaction, while the internal volume of the metal remains plastic enough to withstand long-term mechanical loads. The most ancient is considered to be a method of quickly heating an object over an open fire, accompanied by spraying or jet flow. It is by this technology that a traditional oriental curved knife (kerambit) is made. Surface hardening can also be carried out by means of intensive cooling. Also known are gas-plasma, induction, laser and other methods. Some of them should be considered in more detail.

HDTV

In the mid-1930s, the Soviet scientist V.P. Vologdin invented a method for imparting a given uneven molecular structure to large parts using high-frequency currents. Mechanical engineering was developing rapidly, the industry needed technology to ensure mass production without compromising on quality. The surface hardening of the HDTV is based on the phenomenon of induction. A feature of the method lies in the dependence of the thickness of the heated layer on the frequency and magnitude of the current in the emitting frame. Moreover, the result is highly predictable, therefore, quality control is greatly simplified. In addition, the method is applicable for processing large-sized products and units, like crankshafts and other large objects that can be moved along the inductor, sequentially exposing the entire length. According to this technology, it is difficult to select parameters to process small and flat objects, for example, a knife. Surface hardening by high-frequency currents is applicable to relatively bulk products, the strength and wear resistance of which depends on the mechanical properties of the upper layer.

Features of the application of the HDTV method

The method was developed under the conditions of rapid development of the machine-building industry, the main one for the defense potential of the USSR, which was manifested in the specifics of its application. The most important parts of tractors, tanks, automobiles or airplanes have dimensions that do not allow them to be placed in the frame of a compact inductor; it was too expensive to make equipment for each of them, and if it was designed for the largest dimensions, the energy costs became huge. However, induction surface hardening is used for any product, from relatively small to huge. For example, gears are exposed to HDTV sequentially, turning “tooth by tooth”. Elements of crankshafts and cardan shafts are warmed up continuously and sequentially, moving inside the fixed frame of the inductor, while the cooler (sprayer) is included in the process immediately after it. In the terminal unit of the installation, the workpiece is immediately irrigated with water sprays (hence the name, consonant with “spray”).

Well, products with a small hardening surface are placed in the entire inductor and cooled in the same way.

Laser

This device, nowadays used quite widely in various fields of human activity, has found application in metalworking. The method does not require subsequent cooling, since the effect of the beam is short-term and it affects the uppermost layer of the metal, causing the desired changes in the crystal structure. "Laser sharpening" really provides for a long time there is no need to sharpen the cutting tool (mainly for them it is used), if this method is really used in the manufacture. However, it should be borne in mind that in our counterfeit age, the inscription on the product does not always correspond to the truth. Sometimes a cheap butterfly knife is also decorated with such a stigma and sold on a street stall. Surface hardening with a laser beam is not an expensive technology; it is available only to leading manufacturers of tools.

Cold

The physical basis of the method was the discovery of the phenomenon of increasing the hardness of steel as a result of the transition of the austenitic structure to martensitic during deep freezing. Such surface hardening is carried out according to the method developed by A.P. Gulyaev, N.A. Minkevich and S.S. Shtenberg in the USSR. It is applicable for carbon (containing more than 0.5 percent C) and alloy steel for special purposes, for example, made for the manufacture of high-speed cutters and other special tools.

Electric heating

In general, it is built on the same principle as induction hardening, with the only difference being that the heating is carried out resistively, due to the passing current of large values and the resistance of the part. The frequency of the applied voltage exactly affects the depth of the heated layer, and the higher it is, the thinner it is. The surface of increased hardness can be from fractions of a millimeter to several of its units. It depends on the requirements for the product and its size. Compared to HDTV, the electroresistive method has a wider range of currents, temperatures, and layer depths. With its help, for example, an object as mass and requiring special quality as a soldier's bayonet-knife can be made. Surface hardening with electric heating requires a technologically advanced cooling mode in oil, water or other heat-absorbing agents.

conclusions

So, the main task of surface hardening is such a distribution of the crystalline structure inside the product, in which varieties of sorbitol or troostite remain inside it, and a martensite layer forms outside. This can be achieved by several methods, from the simplest and oldest to the most technologically advanced and modern. In any case, high-quality hardening of steel requires high qualification and accuracy of compliance with production regulations. A product made in accordance with all the rules cannot be cheap. For this reason, a good kitchen knife and kerambit are expensive. Laser beam surface hardening is most common for cutting tools.