Elevators are devices that are necessary to lower the temperature of the coolant entering residential buildings. This device reduces the temperature of the water due to partial mixing with cold liquid from the return pipe. Currently, water-jet elevators are not at every TPP. Let's take a closer look at what this device is, how it works and whether it makes sense to install it. Also consider other types of elevators. For example, those used in grain warehouses, etc.

General information

It is no secret that the incoming network coolant must comply with the standards. It is important to consider hardness, acidity, pressure, as well as temperature. According to established standards, water coming from mains should not have a temperature above 95 degrees Celsius. What is the reason for this, we will not consider, but the fact remains. However, these standards are far from always respected. Often the temperature of the coolant in the mains reaches more than 130 degrees. To solve this problem, it is necessary to install elevators. This device will help lower the water temperature to normal. Moreover, this is one of the most effective means to control the flow of coolant.

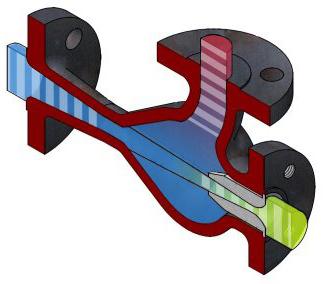

Water-jet elevator

Before talking about the principle of operation, it is necessary to understand the device. Such an elevator consists of a metal casing, in which there is a chamber for mixing the coolant, and a nozzle. The superheated liquid exits directly from the nozzle and immediately enters the mixing chamber. Moreover, the whole process is carried out at extremely high speeds. Because of this, the so-called injection occurs, which is the main reason for the suction of water from the return pipe. Changing the nozzle diameter allows you to adjust the flow rate of the coolant, as well as the outlet temperature. We can say that the water-jet elevator acts as a circulation pump and mixer. It is interesting that the device is completely non-volatile and operates on the differential pressure in the network in front of the elevator and in the device. By the way, the available pressure (differential pressure) should have a ratio of 7: 1 with respect to the resistance of the heating system.

Is such a device needed?

In fact, answering this question is quite difficult. Today, not everyone pays attention to compliance. In addition, the quality of the mains supplying water to residential buildings leaves much to be desired. In most cases, not overheated water comes to us, but vice versa. Most likely, this is the fault of the CHP, where temperature conditions are not respected. However, for the effective management of the heating unit in the building, a heating elevator is required. It will help if necessary to lower the temperature of the coolant to normal. In addition, this device does not require regular maintenance and calibration. All that is required is to select the correct nozzle diameter and periodically inspect the unit for visible defects. If you need to change performance, install another, more economical nozzle. However, the selection of the correct diameters of pipes and nozzles for the assembly should be carried out only in the design office.

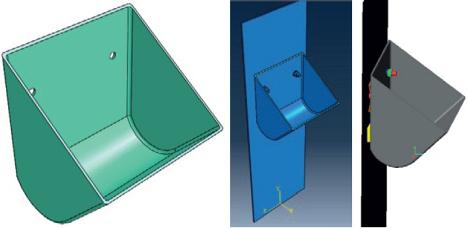

All About Bucket Elevators

The device is a vertical conveyor, which is used to move bulk, granular, lumpy and other materials in a strictly vertical position. We can say that among such carriers this is considered the most popular. Firstly, its dimensions in the cross section are small, and secondly, there is a wide opportunity to adjust the performance of the device. It is noteworthy that the so-called elevators have a closed housing, in which the load is located during the ascent. From this it follows that the material is protected from environmental influences and is in complete safety.

The design is extremely simple and includes a shoe - loading station, head - drive station, and also there are elevator shafts. Material can enter the loading station in several ways (by bucket or by gravity), then it enters the buckets, which move along the elevator shafts to the upper point, from where the unloading takes place. Bucket elevators provide high reliability due to an extremely simple design. In addition, the energy costs of such equipment are at a very low level and are unparalleled.

About grain elevators

We can safely say that chain and belt elevators have found wide application in various industries. Today they are used in almost all grain plants. There are such elevators at mills, bakeries, flour mills, etc. Of course, such elevators are designed taking into account the use in heavy conditions, so the chance that the equipment will fail or fail is minimized. Along with a long service life, it was possible to achieve uniform transportation of grain and other products, which is extremely important in the grain industry. Typically, the grain elevator is equipped with removable panels. This is necessary exclusively for quick maintenance of equipment if necessary. In addition, sectional assembly is used, which makes installation quick and extremely accurate.

More about grain elevators

Such elevators provide a very good level of performance. At the same time, the absence of nodes that are difficult and difficult to maintain virtually eliminates long-term equipment downtime in the event of a failure of a particular element. In addition, modern elevators are equipped with a braking device, which completely eliminates the reverse stroke. An explosion arrestor is also installed. It will not be superfluous to say that the equipment may differ depending on the project. Sometimes elevators of increased strength and performance are manufactured, the engine of which can work for quite a while without rest. If production requires it, elevators are installed that can lift the load to a height of 175 meters with a bucket width of 16 to 200 centimeters. If the cargo is light, then a special design is used to make transportation even more profitable from an economic point of view. In principle, such elevators are a profitable and appropriate solution.

Something else interesting

It often happens that you cannot use a belt elevator. If this is an indispensable device for the transportation of granular materials of small and medium size, then problems with other goods may arise. In this case, it is advisable to use chain elevators that are able to work in more severe conditions. For example, they are used to move hot loads, both granular and lumpy. Both in the belt and in the chain elevator, the bucket volume can vary from 1 to 18 liters. At the same time, productivity varies over a wide range from 5 to 100 cubic meters per hour. As noted, in the event of an unexpected stop of the device, brakes are installed that will leave the buckets in the position in which they are now. Of course, the elevator, the price of which is formed depending on the performance and volume of the bucket, must be purchased only from trusted companies. For example, a noriya with a capacity of 10 t / h will cost 100,000 rubles, but full grain elevators will cost from 4 to 100 million rubles.

Conclusion

As you can see, elevators are devices necessary for the vertical transportation of goods. But there are water-jet or heating appliances that have nothing to do with chain, belt or bucket elevators. Nevertheless, it must be understood that vertical transport devices must be manufactured without deviations from the norms and state standards, because any malfunction can lead to the fall of a heavy load and personal injury or death of workers. At the same time, a water-jet elevator is needed to keep your radiators and heating system intact.