For the smelting of cast iron in the modern metallurgical industry, blast furnace is used. This is a shaft- type furnace , which is not a very complex design, which, however, looks impressive. To bring the production of pig iron to perfection, mankind had to accumulate centuries of experience.

Partly explains what a blast furnace is, the Old Slavonic root of its name. "Smoke" means blow.

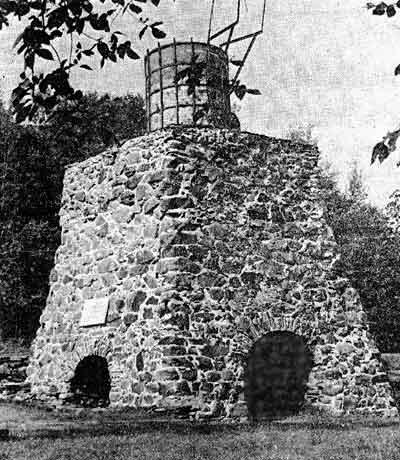

Ancestors of blast furnaces - grooms

In the Middle Ages, people needed different metals. Weapons and tools were made of steel, flexible and solid, and ordinary iron was used for household items. Syrup-blast furnaces have been used to obtain the right metal for a very long time, for millennia, and they fully met the needs until the stocks of fusible ores were depleted. High temperatures were achieved by increasing the height (the thrust intensified), the air was also pumped by hand bellows. However, over time, Europeans had to switch to lower-quality raw materials, which served as an incentive for progress. Shtukofen became that invention after which the first blast furnace appeared. It was a closed oven operating on a specific cycle. It was required to load ore, coal, then there was heating with blowing (manual efforts were not enough, therefore a drive from water wheels was used), after which it was necessary to wait for cooling and extract the metal, separating it from scale and other unsuitable by-products called kritz. The main advantage of gentry was the better concentration of thermal energy due to the closed volume during the working cycle, due to a decrease in its leakage into the atmosphere.

Pig-iron civilization

The main problem of medieval metallurgists in the thirteenth century was the refractoriness of iron. When pig iron was obtained in ore (that is, an iron-carbon alloy with a carbon concentration of 1.7% and higher), then they were surprised at its low melting point, but they were not enthusiastic. It was easier to obtain the obtained metal than steel and especially iron, but its mechanical qualities, from the point of view of the then consumers, left much to be desired: too fragile and not strong enough. However, in just two centuries, the attitude towards cast iron has changed. Firstly, it turned out to be a simple matter to extract it from the furnace, it could simply be drained in a molten form. Secondly, this metal has nevertheless found its application, and it is very diverse. And thirdly, it was a raw material for further purification from excess carbon, and it became much easier to get steel from it than from ore. So, after centuries of experimentation, the most productive metallurgical technology was found, and blast furnace invented. The furnace in the Westphalian city of Siegerland (second half of the 15th century) could operate with a continuous cycle for several years, producing over one and a half tons of cast iron daily. Then it was a lot.

Blast furnace structure

Only having been close to this gigantic stove can you understand how big the modern blast furnace is. Photos give an idea of its cyclopean sizes only when they depict a person who appears as small as an ant. However, despite the impressive appearance, the principle of action remained the same, medieval. The design includes five main components. The upper one, the top, is designed to load raw materials and their uniform distribution inside the furnace. Below it is located the part of the conical shape in which heating and the recovery process take place (about it later). The third unit on top is called steaming, there is iron melting. Then another conical part, this time tapering downward, is the shoulders, in which carbon monoxide (reducing gas) is released from coke. And at the very bottom is the hearth from which the finished product and production waste are extracted .

Process chemistry

Chemical processes are oxidizing and reducing. The former means a connection with oxygen, the latter, on the contrary, its rejection. Ore is an oxide, and in order to obtain iron, a certain reagent is required that can "select" excess atoms. The most important role in this process is played by coke, which produces a large amount of heat and carbon dioxide during combustion, which decomposes at high temperature into monoxide, a chemically active and unstable substance. CO strives to become dioxide again, and, meeting with ore molecules (Fe 2 O 3 ), it “takes away” all oxygen from them, leaving only iron. There are, of course, other substances in the raw materials, unnecessary, which form waste called slag. This is how the blast furnace works. This, from the point of view of chemistry, is a fairly simple reduction reaction, accompanied by heat consumption.

What is a modern blast furnace?

The service life of the blast furnace is relatively small for structures of this magnitude - about a decade. During this time, the structure is subjected to heavy loads, burdened by thermal heating, then capital repair or demolition is required. The production of pig iron cannot be called harmless; it is associated with emissions of phosphorus, sulfur and other not very useful substances into the atmosphere. In the aggregate, these circumstances prompt many countries to curtail metallurgy or to modernize it (especially if the industry is basic and budget-forming). A modern blast furnace is a system that is quite simple in principle and requires, however, a complex control scheme with numerous control loops that ensure the most efficient use of raw materials and energy.