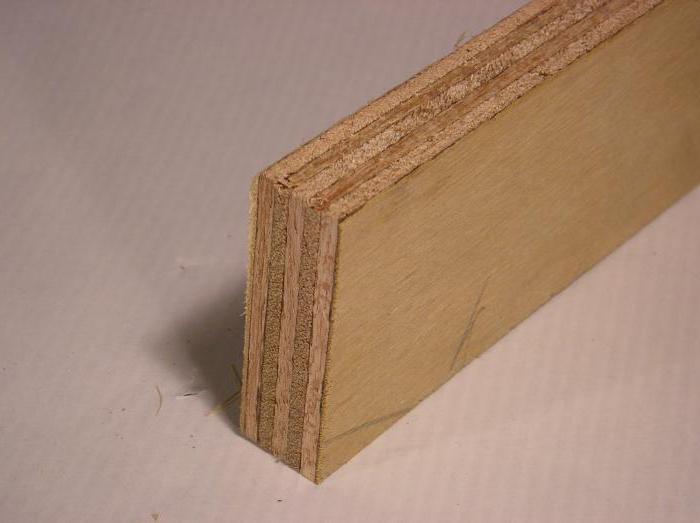

If you decide to purchase plywood, then first you need to familiarize yourself with its varieties. This material is a canvas based on wood. Sheets are made by gluing peeled veneers. In one product, the number of layers can vary from 3 to 23. As a rule, the described material is made by technology, which involves the location of wood in adjacent sheets mutually perpendicularly. However, on sale you can find options in which the veneer is located in one direction. The thickness of the outer layers is 3.5 millimeters, while the inner layers are 4 millimeters. The technique may involve the use of varnishes and resins of various properties, this gives the final product certain characteristics.

general description

Depending on what mechanical surface treatment was used, some types of plywood can be distinguished. Thus, on sale you can find polished, unpolished material or one that undergoes similar processing on one or two sides. These canvases can be made from different types of wood, among them poplar, birch, needles or aspen can be distinguished. You can also find combined material, which has several varieties of wood material. Birch plywood is considered very durable. This is due to significant physicochemical parameters of wood, which is supported by the multilayer structure. As for the coniferous variety of canvases, they are made of pine, which provides high strength with low weight. These types of plywood are successfully used in the construction of houses. The grade of material is determined by the number of knots per square meter. Thus, in the building materials market it is possible to purchase the described material in four grades.

FC plywood

Considering the types of plywood, you will surely pay attention to this variety, which refers to moisture resistant materials. In the production process, urea resin is used to glue veneer sheets . These sheets are intended for indoor use. The material is not able to crack through, and is also quite easy to process. This applies not only to sawing, but also to drilling. For work, you can use a saw or an electric jigsaw. The canvases are quite easy to attach to each other, and if necessary, they can be fixed to any surface using self-tapping screws. This material is called universal, since it can be used both for private construction work and in the manufacture of furniture. Considering the types of plywood, you, first of all, pay attention to FC, in its production the spruce or birch veneer is most often used. When comparing material from birch and coniferous wood, it can be noted that the canvases will differ in density, the first option has this indicator within 650 kilograms per cubic meter, while spruce and pine show a density equivalent to 500 kilograms per cubic meter.

Area of use of FC brand plywood

The types of moisture-resistant plywood described above are used in the decoration of walls and ceilings. When carrying out these works, canvases are used in which one of the sides has the highest grade. You can find this material as a rough base for laying laminate and parquet, using sheets whose thickness varies from 5 to 15 millimeters. To do this, you can purchase low grades, since the sheets will be cut, which indicates the ability to get rid of defective elements. Using canvases in tandem with a substrate, it is possible to increase the heat and sound insulation qualities. If you will purchase plywood, types, the use of this material you can consider in the article. It is worth considering that FC plywood is used in the manufacture of drawers, shelves, rear walls of cabinets, as well as some constituent chairs and sofas. This material found its application in the preparation of stands, as well as signboards, however, these elements can only be used indoors.

FKM brand material

Considering the main types of plywood, you should pay attention to the mentioned brand. It has improved water resistance properties and is manufactured using technology that involves the use of melamine resins. This variety is unique, since environmentally friendly materials are used for the manufacture. Due to these characteristics, the material gained the opportunity to be used in furniture production. Among other things, FKM is used for interior decorating.

Features FCM

Said material is made using melamine, which is a crystalline, colorless substance. It almost does not dissolve in water. Such resins, unlike phenol-formaldehyde, practically do not decompose when exposed to room temperature, therefore they are widely used in the production of all kinds of household products. Among the distinctive features of this material is the increased moisture resistance, which is sometimes still compared with that of the FSF.

FSF brand plywood

This material is made by gluing veneer sheets together using phenolic resin. This type of plywood has increased water resistance. It is not recommended for interior decoration, due to the fact that phenolic resins are harmful to human health. As a rule, these canvases are used when carrying out exterior finishing works.

Production is made using pine, beech or birch veneer. Among the qualitative characteristics, one can distinguish high wear resistance, as well as resistance to mechanical stress. Most often, this material is used in concrete and roofing, in car building and in the automotive industry.

Pros and cons

Considering the types of plywood for the floor, you should not choose the FSF brand, but it is great for the needs of industry and, if necessary, external work. This material is characterized by bending and tearing strength. At the same time, these characteristics remain almost unchanged with differences in humidity and temperature. The canvases are quite easy to process and drill, it is good to hold screws and nails in them. In addition to toxicity, these sheets are flammable. When exposed to a flame, the material will maintain combustion, while fumes that are quite dangerous for human health will be released into the environment.

Features of laminated plywood

Laminated plywood, the types of which differ in grades and materials in the base, contains in the composition of the FSF. This layer is coated on both sides with a special film. This type of material is used when it is necessary to manufacture formwork. You can use the material repeatedly, which is its great advantage. These sheets are characterized by moisture resistance properties due to the presence of a film as the upper layers. In the manufacturing process, glue is used, which has increased water resistance. The technology involves the use of pine, birch, larch or poplar. Among other things, on sale you can find combined options. This material is most common in the automotive industry, aviation, during railway operations, in shipbuilding, furniture manufacturing, as well as in the trade and advertising fields. In private construction, such laminated sheets can be used for pouring a monolithic foundation. Material is relevant for the device of the floor, roof, walls, as well as for covering the external and internal surfaces of buildings.

Benefits of Laminated Plywood

Cloths differ not only in moisture resistance, but also in high strength. They can be used in the most difficult conditions, for example, at elevated temperatures, humidity, as well as under constant mechanical stress. Chemical aggressive substances that cannot change the qualitative characteristics of the material can affect the surface of the material. Among the additional advantages can be identified long life, affordable cost and ease of installation. Among other things, the material is quite simple to process, it is characterized by wear resistance and environmental safety. Consumers choose laminated plywood also because of their attractive appearance. Upon purchase, you can choose the color of the film and the density. Manufacturers present for sale options, the surface of which can be smooth or embossed.

Sheet thickness

The types of plywood and thickness described in this article will help you make the right choice. For example, the last parameter can vary from 3 to 30 millimeters. In this case, the ply varies from 3 to 21 units. Thus, for a material with a thickness of 27 millimeters, the number of layers will be 19, while for 9 mm plywood, the number of layers varies within 7.

The maximum deviation can vary from 0.4 to 1.2 millimeters. This indicator increases in direct proportion to the thickness of the sheet. Do not overpay, if there is no need to use plywood of impressive thickness, such expenses will be inappropriate. That is why it is recommended that you familiarize yourself with the assortment presented in the store before purchasing.