In addition to the well-known flexible tiles, very often roofing roofing material is laid on the roof of small buildings, which helps protect the inside from moisture. In addition, this material is used for waterproofing the foundation and other structures. For several decades now, he has been doing his best, providing reliable protection at an affordable price. In addition, the installation process is not an intricate soft roof device. The technology is quite simple and reliable, so organize waterproofing is obtained in a short time. The disadvantages include a not very long service life and the lack of numerous design options.

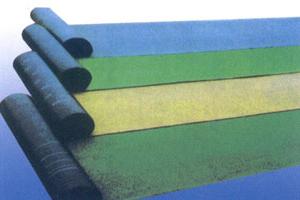

It turns out roofing roofing by impregnating various bitumen surfaces of special cardboard. Products used to organize the roofing carpet usually have a front surface with a coarse-grained coating. As a rule, they are not used in the lower layers of the heat-insulating layer. As for the width of the canvas, it can be completely different. However, rolls from 750 to 1050 mm are most often produced. When coordinating with the customer, manufacturers can resize.

Today, roofing roofing material is only one of the varieties of bitumen

roofing materials. Similar products, there are more than sixty items. Despite this state of affairs, they all have a similar chemical composition and manufacturing technology. A large number of residential and industrial buildings erected in the post-war years have such coatings. Well established and another analogue of roofing material. Rubemast is a weldable material supplied in rolls. The main difference from the above product is the presence of a saturated layer of bitumen from the bottom of the canvas.

Although the technology of

the roofing device is becoming more and more complicated every year, nobody is going to refuse bituminous roofing materials, since in some cases their use is considered the most optimal option. In addition, with each year, modified analogues and fused membranes appear. Increasingly, fiberglass or synthetics are used as the basis. Some of the representatives of bitumen products have almost gone out of use.

Once on the store’s counter, the roofing roofing material should not have holes, cracks, folds or other flaws. A protrusion at the ends of the roll of more than 15 mm is not allowed. The party is allowed to use no more than five percent of the composite rolls. The cardboard base is impregnated completely over the entire thickness of the canvas. In the context of the material should be black, turning into a brown tint. The presence of unimpaired places on the surface of the product is not allowed. Each roll contains a packing strip of paper with a width of at least 500 mm. Marking is carried out using a special stamp indicating the batch number, standard, year of manufacture and information about the manufacturer.