Thin walls are the reason that 30-35% of the heat simply goes through them. Thus, almost a third of the money that is paid for heating disappears in vain, and if you collect it in a year or two, you get a pretty decent amount, which, if you save, can be spent on anything: relaxing by the sea, traveling to your favorite country, buying new furniture - a lot of options.

But how to save? Do not sit in a cold house? To start saving, you must first spend - make insulation of the facade with mineral wool. The technology of this process is quite simple, you can do all the work yourself. The only thing needed for this is to know how to choose the material, how to handle it and what is the sequence of work. Further on this and much more in more detail.

Selection basics

But for the material to really be able to perform all functions and keep warm in the house, it must be only of high quality. Far from all types of insulation that are currently on sale in the construction market, we can say that they are of high quality. However, there are companies that produce mineral wool that meets all the requirements and has all the necessary properties. These are Beltep, IZOVOL, Paroc and others.

Rockwool leads the list of the best manufacturers. This is a branch of a Danish company. And he is not alone: throughout the country there are factories of this brand that offer high-quality products without price markups.

Insulation characteristics

Minvata "Rockwool" - one of the best materials, which is characterized by many enhanced characteristics. The most important of them are:

- Excellent soundproofing. Due to this, the fibers are chosen to improve the acoustics of rooms, the manufacture of noise screens.

- Low thermal conductivity.

- Environmental friendliness, which is confirmed by the certificate EcoMaterial Green.

- Vapor permeability.

- Refractoriness - mineral wool can withstand temperatures up to 1000 degrees C, while for other manufacturers this figure is 600 degrees. In case of fire, the fibers do not shrink, therefore, voids that are very dangerous at high temperature do not form inside.

- Easy installation.

- An opportunity to choose an external heater in rolls or plates.

- Durability. Moreover, during operation, the fibers do not collapse, do not deform, and hold dimensions well.

In addition, which is very important, Rockwool insulation does not rot, it is not affected by rodents and various microorganisms.

Product Overview

The Rockwool company produces several brands of mineral wool. Among them, the most popular are:

- Wentirock Max. This is mineral wool in the form of mats, intended for use in the insulation of enclosing walls, high partitions and external walls , followed by cladding in the form of glass, stone, and corrugated board. The cost of mineral wool Wentirock Max - from 600 rubles. for 1 square. m with overall dimensions of 100 x 60 x 10 cm.

- "Conlit." Such a name are plates and shaped products. Available in two versions - with and without aluminum cladding. Some products are finished with a layer of fiberglass. This type of product is intended for installation at facilities that are subject to increased fire safety requirements. To fix Conlit boards to the surface to be coated, you will additionally need to buy glue specially designed for this purpose.

- Light Butts. These are lightweight water-repellent heat-insulating plates that do not shrink and are easy to install. The cost of “Light Butts” brand mineral wool depends on its thickness (5 or 10 cm) and plate sizes and varies from 450 to 565 rubles.

In total, the manufacturer produces 24 types of insulation, which allows you to choose the most suitable option for a specific purpose.

Material selection

Before you buy your favorite mineral wool, you must definitely pay attention to where it will be installed and whether it is intended for this. So, if the installation of mineral wool will be carried out outside the building, then the material should be facade, since it has a higher hydrophobicity, repels moisture and has a good density. The insulation intended for indoor installation has lower properties and will not cope with its purpose if it is installed outside the building.

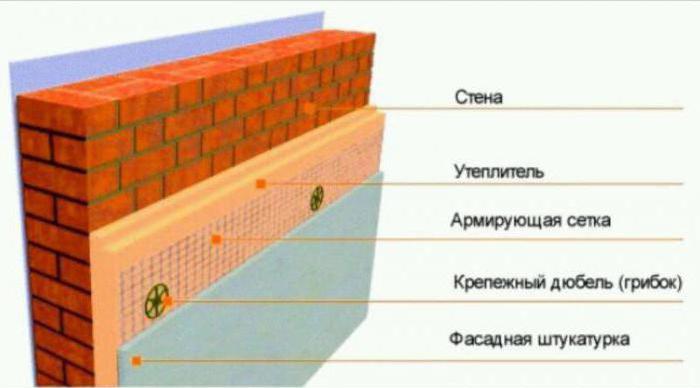

Unfortunately, mineral wool, like any building material, has not only advantages. He also has drawbacks - the need to strictly comply with the process. If the manufacturer's recommendations for installation are violated, the insulation will lose its heat-insulating properties. One of the violations of technology is the rejection of the reinforcing layer. Such a decision will lead to the fact that cracks will appear on the facade, and eventually expand.

Insulation technology

Experts advise you to carefully and seriously consider the recommendations for installing insulation and properly prepare the walls - this only guarantees the quality of the result, and the process itself will not take much time. How should the facade be insulated with mineral wool? Installation technology consists of several stages. It:

- Work markup.

- Profile setting.

- Installation of insulation.

- Fixation of insulation material.

- Reinforcement.

- Waterproofing support.

- Finishing surfaces.

After marking, it is necessary to remove cement smudges, protrusions, protruding metal pins from the walls, and then remove the wires, drainpipes and other objects so that over time the rust from them does not appear on the facade surface. Then all cracks should be repaired with a solution. After this, it is necessary to apply a substance that protects against fungus on the entire insulated surface. And this must be done, even if the fungus on the wall surfaces is not noticed. If the walls are wooden - they need to be impregnated with an antiseptic.

Facade preparation

Mineral wool wall insulation is carried out in the following sequence:

- Primer walls. Moreover, it is necessary to use a material that penetrates deep into the surface of the walls.

- Mounting rails. It can be wooden bars or a metal profile. Horizontal guides should be the same thickness as the insulating material. Given that mineral wool can be slightly compressed during installation, the profile can be used thinner by 1-2 cm, this is quite acceptable. The distance between the guides depends on the size of the plates.

- In order for the plates to be laid tightly, without gaps and crevices, it is necessary to make the distance between the guides slightly smaller. But this indicator should not exceed 2 cm.

- Fix guides using self-tapping screws or dowels.

- Place Rockwool insulation between the rails. Laying starts from the bottom and ends at the top. You can put the insulation on glue or strengthen it with dish-shaped dowels. If nevertheless there are gaps between the insulating material and the guides, they must be filled using the remnants of the insulation.

- To reinforce the insulated wall, glue should be applied to its surface and gently press the reinforcing mesh. Then from above it is necessary to apply the adhesive again. This will prevent surface deformation and will additionally protect the insulation from moisture.

Installation for siding

If siding is used as the final finish, it is best to arrange a ventilated facade by warming the facade with mineral wool. The technology of this action is as follows:

- Fasten the vertical profile. All elements are installed at a distance of 40-50 cm from one another.

- In the interval between the uprights, the Rockwool mineral wool is laid, which is fastened with dish-shaped dowels.

- The waterproofing membrane closes the insulation. Joints are glued with butyl tape. This must be done to protect the insulation from moisture. Depending on the wall material, staples or liquid nails are used to fix the vapor barrier film.

- Installation of counter-lattice.

- Installation of siding.

Plaster insulation

Insulation of the facade with mineral wool under the plaster eliminates the use of steam and wind insulation and lathing. The work is carried out according to the following plan:

- Fix mineral wool on the facade surface using glue or plate-shaped dowels. At the same time, you need to ensure that there are no gaps anywhere, and the joints of the plates of the next row were located approximately in the middle of the previous row.

- Installation of reinforcing mesh. Cloths are stacked with an "overlap" of 10-15 cm - this will not allow cracking of the plaster.

- When the reinforcing layer becomes dry, an external finish is performed.

- Using a spatula, remove glue streaks.

- If it turns out that the reinforcement did not level the wall surfaces, you can first use rough plastering

- Finish facing. To improve the aesthetic performance of the building, it is advisable to use decorative plaster.

Expert Advice

Those who are engaged in construction professionally argue that it is possible to conduct insulation of the facade with mineral wool yourself. The technology is not complicated, but there are some nuances without which knowledge to perform work at a high level will not work:

- Rockwool mineral wool in plates is best suited for outdoor installation - this material has a high density, so it will not sag over time.

- It is best to take insulation material of such a thickness that it can be installed in one layer. If the installation is carried out in two layers, the seams should not coincide.

- During installation, you need to ensure that there are no voids left - they will be cold bridges that provoke the appearance of condensate.