Since polypropylene pipes are the most common in all industries, devices for working with them are indispensable both in production and at home. Installation of such pipes is carried out by soldering two ends using a special apparatus.

The correct selection of equipment greatly facilitates the soldering process and ensures the quality of the work done.

Principle of operation

A high-quality welding machine for polypropylene pipes should provide comfort in work and perform reliable fastenings. The design of the apparatus consists of a body, a stove and the heater itself.

The soldering process is carried out by diffuse technology and consists of three stages:

- First, the device heats the seam.

- Next, the edges of the pipes are applied to the iron.

- After that, the ends heated to the desired state are connected. In the process, the temperature decreases, after a while the seam hardens and becomes durable.

Each device has individual features.

Overview of welding machines for polypropylene pipes

Among the various models of devices that can significantly simplify the process of fixing elements at home, one should distinguish these types of devices:

- The xiphoid. These devices include interchangeable nozzles that are mounted on through holes or bushings. The heating element is a thermostat. In most cases, temperature data is displayed. Among the positive aspects, increased resistance to overheating is distinguished. The main negative characteristic is poor fixation of the device on the stand.

- Cylindrical. This type is equivalent to professional. The working element is a cylinder, on which various nozzles for pipes are mounted. These models are divided into two types: with a straight and side cylinder (the latter is suitable for more complex jobs).

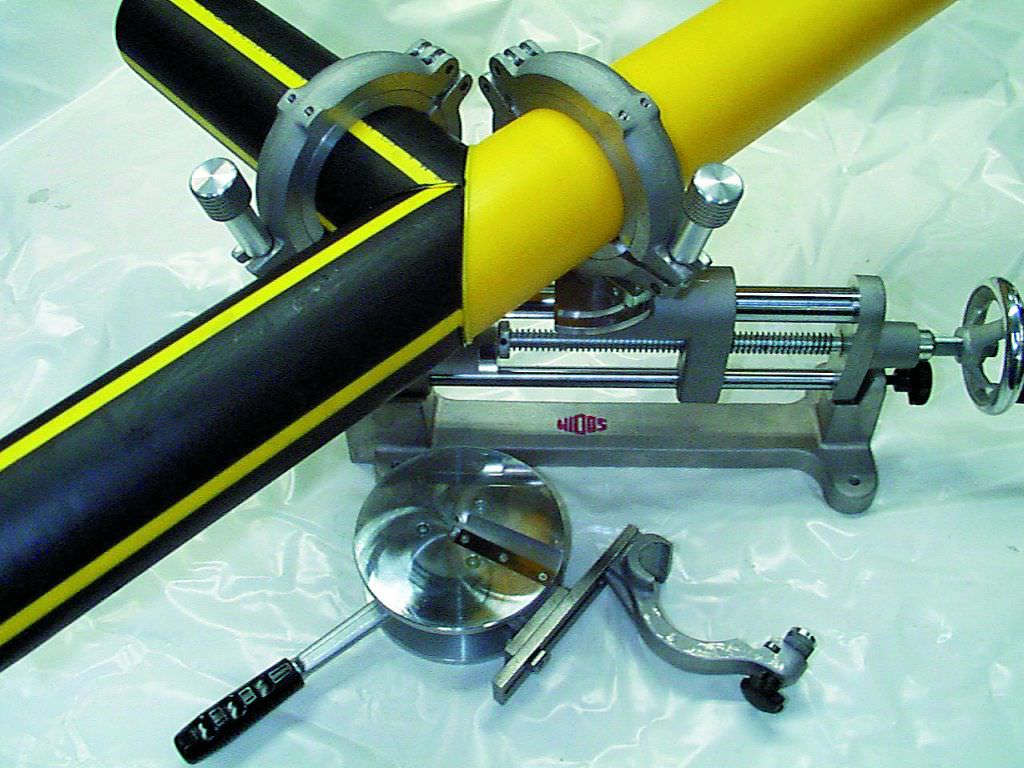

- Mechanical. The working element in such devices is pressure. A feature of mechanical manual welding machines for polypropylene pipes is a built-in dynamometer. With the help of such an element, it is possible to track the amount of applied pressure. Ideal for pipes of small and medium diameters. In the process, special clips are used to fix the elements.

- Hydraulic. A feature of the above devices is the presence of an electrohydraulic drive. Using this drive, you can create a pressure of up to 120 atmospheres. Ideal for use with medium and large diameter structures.

- Bell-shaped. This welding method consists in using a special coupling, which is heated from the inside to fasten parts. This method is considered the most reliable and is suitable for working with products whose diameter is up to 125 mm.

Specifications

The main technical characteristics of the welding machine for polypropylene pipes include:

- power;

- equipment;

- additional devices;

- manufacturer.

When choosing, it is worth considering that the minimum rated power should be:

- for pipes with a diameter of 20 mm - not less than 200 W;

- from 40 mm - 400 W and more.

For home use, the ideal power will be 850 watts.

The device for large diameters. What is the feature

Difficult manipulations with large diameters cause difficulties in work. For soldering pipes with a large diameter, mechanical welding fixtures are the best option.

A feature of mechanical soldering irons is the ability to fix work surfaces with clamps.

Manual apparatus. What are the features

The welding machine for polypropylene pipes of 63 mm and less is used at home. The most common are the so-called irons. “Home” devices consist of:

- heating plate;

- temperature controller;

- holders;

- welding elements that are coated with heat-protective material.

A feature of hand-held devices is their low power. It is worth noting that such devices are suitable for beginners.

What to look for when choosing

To choose a good welding machine for polypropylene pipes, you should pay attention to such criteria:

- Device type. This parameter is individual. For use at home, the most primitive - manual devices, for professional - mechanical ones.

- The presence of a protective coating. This coating provides effective protection of work surfaces.

- Manufacturer and brand. Before buying, great attention should be paid to user reviews about a particular manufacturer and a specific device.

- Power. This criterion is also selected individually. The given power should ensure comfortable operation and reliable welding of elements.

- The number of additional nozzles. The more nozzles, the more universal the model. When choosing, you should also pay attention to the usefulness of components.

- Build quality and apparatus material.

Important! Before first use, check the new device on the remnants of old pipes.

How to choose the right welding machine

When choosing a welding machine for polypropylene pipes, you should pay attention to such characteristics:

- Temperature. A more professional appliance always has a wide temperature range. This ensures comfortable work with any kind of plastic, as well as reliable fastening of the elements.

- Complete set. In addition to the main nozzles, the package may include: a cutter, tape measure, lotions, etc. The cost of the device depends on the number of additional nozzles.

- Speed of work. This parameter directly depends on the declared power. For use at home, a simple device with a power of up to 850 W is suitable, and for production conditions - from 1.5 to 2 kW.

User's manual

In the process of selecting a fixture, it should be understood that the welding technology is in no way dependent on the tool. Seams are soldered according to this scheme:

- First, the joint is prepared: the pipes are cut to the desired size. The tightness of the seam will depend on the quality of the cut.

- Next, they select a suitable nozzle and put it on a soldering iron tip. After that, the tool is connected to the mains and wait a while to warm up the nozzles.

- A sleeve is inserted into the nozzle on one side and the end of the pipe on the other. After heating, both elements are removed and quickly inserted into one another. As the material cools, a seam formation process takes place.

- Exactly the same operation is performed with any docking element.

Rating of welding machines for polypropylene pipes

The most popular devices are:

- Candan The Turkish apparatus is equated to professional. Powerful models (mainly of the xiphoid form) allow you to use three nozzles at once. The kit also includes: special scissors, level and measuring tape. It is worth noting that the average power of Candan is 1.5 kW.

- The welding machine for polypropylene pipes "Bison 2000". It is worth noting that such a tool can be used by both professionals and beginners. Among the main advantages are: high power, the presence of non-stick coatings and two heating elements at once. The heating indicators are attached to the device body, which notify the user about the temperature of the device.

- Among domestic manufacturers, Sturm received the greatest user trust. Cylindrical heaters have a fairly high power (about 1.8 kW). The kit also includes: 4 nozzles, Allen key. Users note that at a relatively low cost, the device meets the specified characteristics and is suitable for both homework and small production.

- Valtec. Powerful fixtures (up to 1.5 kW) are budgetary but effective. Most of the Russian-Italian-made devices are made in the form of a “sword”. The device is suitable for welding pipes with a diameter of 20 to 160 mm.

- The welding machine for polypropylene pipes "Resanta". This device has high power and optimal voltage. Rugged housing protects the device from mechanical damage. The maximum working temperature is 300 o C. These characteristics allow you to perform work quickly and efficiently. The diameter of the additional nozzles is from 20 to 63 mm.

- Polys P-4 is also a popular hand-made model. Low power (850 W) does not affect operating efficiency. It is worth noting that the kit includes scissors, additional nozzles and a clamp. Ideal for use at home and in small production.

Important! Before starting work on pipe welding, you should carefully familiarize yourself with the basics of soldering technology and carefully study safety precautions.