A heating circuit with a water circuit is a universal appliance designed for space heating. Equipment in this form combines the function of titanium and boiler.

Need to use

These stoves act as the best choice for heating houses within the country house, as well as country houses. They are equipped with a built-in heat exchanger, which is located in the furnace. It can also be in the chimney channel. Some types of structures operate in the mode of circulation of heated steam, which may not be available in a conventional circulation system, where hot water is present.

Features of heating

Heating with a fireplace stove with a water circuit is a system that is made of cast iron or boiler steel. Such devices are designed to operate under high vapor pressure. They can be used as an additional source of heat or as the main heating of the premises of the house. In such furnaces, the heat exchanger is located inside the heater and may have a certain design. As a rule, the basis for the exchangers is sheet steel or metal pipes. The material must have a thickness of more than 5 millimeters.

Heat exchanger

Heating with a fireplace stove with a water circuit usually involves a heat exchanger, which is made of sheet steel. This option has gained great popularity, due to the ease of processing when performing the register and ease of care. Thus, equipment owners can easily clean surfaces of combustion products that tend to settle. A good register should ensure the highest possible temperature of the coolant, guaranteeing uniform circulation. If there is a need, then you can make a heat exchanger yourself, this process can not be called complicated. However, the master must have good welding skills.

The principle of heating

Heating with a fireplace stove with a water circuit provides for the passage of heated gases through the channels of the heating tank. They are designed to transfer heat energy to water. In the furnace, several tanks can be used at once, with the help of which the efficiency is increased. The first tank is designed to heat water, while the second will increase heating until steam is formed. For the maximum possible warm-up, a separate room should be allocated for the boiler.

Making a furnace yourself

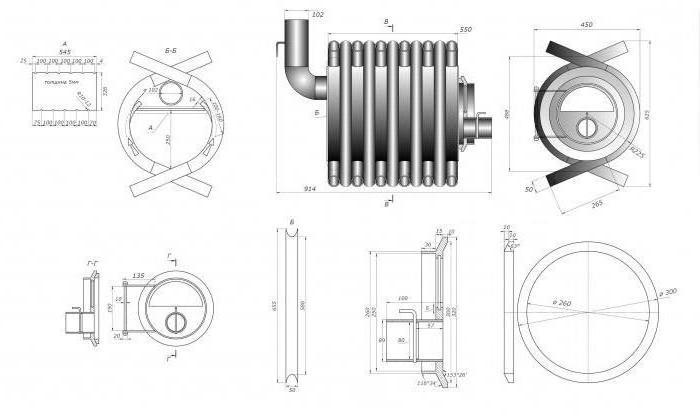

If you decide to provide heating with a fireplace stove with a water circuit, it is recommended that you make the main structure of the system yourself. Before starting the process, you need to worry about the presence of a register, heat exchanger, coil or boiler. In the absence of one of the listed items, you can purchase the missing components. If you decide to do the manufacturing yourself, you will need metal pipes or sheet metal. The fireplace stove with a water circuit wall-corner "Bavaria" is also great for this. The minimum thickness of steel that will be used in the manufacturing process of the heat exchanger is 3 millimeters. The main requirement for the heat exchanger is to ensure maximum heating of the water and the uniformity of its circulation. More common and easy to use are designs based on sheet steel. Despite the fact that their heating area is smaller, in comparison with the pipe option, they are easier to clean from fuel combustion products.

Recommendations for work

The heating system of the fireplace stove with a water circuit involves the use of a certain technology of work. For the manufacture of a heat exchanger, you will need a pipe segment, the size of which is 5 x 6 x 4 centimeters. Prepare a rectangular profile and pipes with a diameter of 4.5 centimeters. They will be needed for drainage and water supply. The dimensions of the heat exchanger must be determined depending on the area of heating and the size of the furnace. The distance between the heat exchanger and the furnace should be 4 centimeters, otherwise the coolant will boil, which will cause the destruction of the entire system. If a fireplace stove with a water circuit, reviews of which you can read below, requires a circulation pump, then the aforementioned distance should be reduced to 30 millimeters. The wall thickness of the heat exchanger can vary from 0.3 to 0.5 centimeters. If the walls turn out to be smaller, it is very likely that the material will burn out, if more, the fuel consumption will increase. In order to ensure efficient heating of the heat exchanger and level the thermal expansion of the metal, care should be taken about the gap, the width of which is 1 centimeter. It will compensate for this expansion. If the heat exchanger is made of pipe, then the clearance should be higher than the mentioned value. This will allow more efficient heating of the heat register. Among other things, you facilitate the cleaning and maintenance of the structure. If you decide to make a fireplace stove with a water circuit yourself, you can prepare the drawings yourself. When arranging stoves that have a heating and cooking function, it is necessary to provide for the possibility of removing the furnace to clean the heat exchanger. Ash will accumulate in the space between it and the stove, which adversely affects the operation of the system.

Masonry should be carried out by specialists who have experience in this field. If you approach the process incorrectly, then the system will be disrupted.

Recommendations of specialists

To equip the described heating system, you can purchase a Bavaria fireplace stove with a water heating circuit, however, some prefer to erect the structure on their own. The brick must be connected using a solution based on sand and clay. If there are bumps and transitions, then with the help of a grinder it will be necessary to cut off a small plate of the product, and then install it in the place where there is a transition. Do not cover the area with clay, because during operation it will lose strength and crumble. After the oven dries, you can install a heat exchanger, there are two options for carrying out these manipulations. The first involves an in-place installation. In this case, the use of stoves and heating and cooking structures that have a tiled surface is permissible. In this case, you will need to remove the top cover and install a heat exchanger. A hole should be made in the firebox wall, in which there will be pipes going to the register. The second option involves disassembling the top of the device. This method has gained wider popularity. After installation, the appearance of the oven will not be changed.

Reviews on the Bavaria furnace

The fireplace stove with a Bavaria water circuit has established itself among consumers. It is of high quality and manufactured on German equipment. According to users, the distinguishing features are ease of installation, low cost and functionality. The stoves are laid out with fireclay bricks and have a clean burning system, which allows to increase the visibility of the flame. Fire chambers of designs are made of 6 mm steel, and is also supplemented with a cast-iron grate. Consumers like the fact that the device is based on high-quality steel, from which the furnace circuit is made. This equipment is characterized by high heating power, which can reach 9 kilowatts. As users emphasize, this allows you to heat rooms, the volume of which varies from 80 to 150 cubic meters.