Turning of wood and metal blanks is widespread not only in the manufacturing sector, but also in everyday life. This is a whole group of technical operations in which cutting, drilling, turning, grinding, etc. are performed. A modern home lathe is a mini-complex with a power plant and working bodies, even a layman can cope with.

General device design

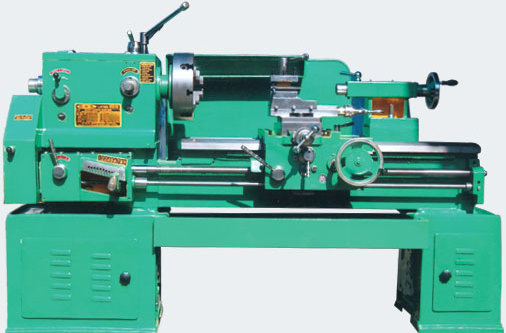

Almost all lathes are based on a metal platform - the bed, where the functional elements and auxiliary devices are located. It is immediately necessary to divide the entire segment of this equipment into floor and table units. Accordingly, the former are installed on the floor and fixed with screws to the foundation base, while the latter are small and can be attached to workbenches of a suitable size. In some versions, home desktop lathes allow the optional ability to install metal legs to extend the bed. This approach is used in cases of processing blanks of non-standard shapes.

Also included in the standard design is the headstock, which houses the power mechanics. This part contains the spindle, gearboxes and gears, torque transmission mechanisms, etc. To convert the return movement into translational, a special apron is provided, and the support transfers the force to the cutting organs to move them. The functional set of cutting, drilling and grinding tools depends on the specific design of the machine.

What tasks does the lathe solve?

In the household, such equipment may be required both for standard processing operations and for solving technologically challenging tasks. In particular, it is possible to sharpen a tool at a lathe's power, saw wooden workpieces, create holes in metal parts, chamfer and clean surfaces. As for more complex jobs, for example, a metal lathe for the home can be used in carving, making curved grooves with it and selecting fillets. Models of units with a copier function also serve to form texture surfaces with specific parameters on wooden and metal blanks. Moreover, such equipment is without fail provided by microprocessor technology with the possibility of software control of the workflow.

Performance data

Household models of lathes have a lower power potential and their processing parameters are generally not as high as in cases with industrial counterparts. The averaged characteristics can be represented as follows:

- Power - for desktop lathes for metal for the home, engines for 300-500 watts are provided. Around the same potential get and units for woodworking. Stationary floor versions are equipped with power plants for 750-100 watts.

- Number of speeds - increasingly smooth infinitely variable speed control is used, and in the case of step-by-step adjustment, the number of modes can reach 10-15.

- Speed - The standard frequency range varies from 500 to 2500 rpm.

- Weight - household models are characterized by a weight of about 20-30 kg, although there are many different compact or structurally expanded units that go beyond this framework.

- The length of the workpiece is from 300 to 1000 mm. Again, much depends on the design of specific equipment.

Types of metal lathe

Among the most popular types of such machines stands screw-cutting. It is provided with a drill chuck, which makes it suitable for making holes, turning, forming grooves and grooves, aligning and cutting. You can also perform threads on it using dies, cutters and taps. A milling lathe for the home is also popular, which is often used for straight turning, chamfering and fillet sampling. Some operations, depending on the nozzle, intersect with screw-cutting models - for example, using milling equipment, you can perform the same thread with holes, but in a different format. Less common types of lathes for metal include rotary and revolving units. The first is suitable for working with large workpieces with a diameter of more than 200 cm, and the second is specially used for machining parts from a calibrated bar.

Types of Wood Lathe

Equipment for working with wood at home can be classified and depending on the operations performed, and by the method of control. As for the first feature, models for drilling, milling units, grinding and grinding are also highlighted. Moreover, machine tool manufacturers themselves are paying more and more attention to the concept of universal equipment that combines several functions at once. In contrast to metal processing, wood in this regard provides more structural possibilities. According to the sign of control, the wood lathe for the house is presented in two varieties. These are models with manual and automatic control (CNC). The choice of a particular version is determined by the nature of the operation of the machine and the complexity of the work performed. For standard operations, experts advise you to purchase machines with the possibility of step-by-step adjustment of speed and center-to-center distance for setting the workpiece in lengths of 250-350 mm.

Conditions for working with lathes

It is advisable to use the equipment in a specially designated room with an air temperature of 1 to 35 ° C. The workshop should have a positive temperature - especially before starting the engine, it takes several hours to warm up, otherwise there will be a risk of breakdown due to accumulation of condensate. It is important to organize a reliable surface for the lathe. For the house, as already mentioned, desktop models are often used, but even in this case, the requirements for the installation surface remain. The table or workbench must have a stable supporting base. For power supply, a single-phase 220 V network is usually provided, provided by grounding and a safety block.

Operational Features

The workflow consists of several stages, the main ones being setting up the machine and setting the workpiece. As for the settings, it is performed manually or automatically - again, it depends on how you manage a particular model. To fix the workpiece, a conventional home lathe has a special clamping tool with guides. To secure the gripping of wooden elements, gearing devices or faceplates with holes are often used. Then it remains only to adjust the processing parameters with a rotation speed and start the unit into operation.

Finally

Although processing machines are still associated with manufacturing equipment, the household model segment is expanding rapidly. These products are becoming more accessible to ordinary users, which is also facilitated by lower prices. For example, a metal turning bu-machine for a house of small power up to 500 W can be purchased for only 5-7 thousand rubles. A full-format processing complex with wide functionality on the market is estimated at 15-20 thousand. Of course, during the operation it is necessary to prepare for additional maintenance costs, but the quality of processing parts in most cases justifies such investments.