If it comes to autonomous heating, then you will surely recall such a device, which is called buleryan. In other words, such an assembly has a firebox, to which several bent tubes are connected. The design allows you to burn different types of solid fuels, including firewood, with high efficiency.

Is it worth it to make

Such miracle stoves on industrial wood have an impressive cost, you will have to pay more than $ 200 for one model, but the price increases depending on the size of the furnace. Despite the fact that the design of the furnace is somewhat more complicated compared to a conventional potbelly stove, many craftsmen undertake to make a buleryan with their own hands.

Design features of the miracle furnace

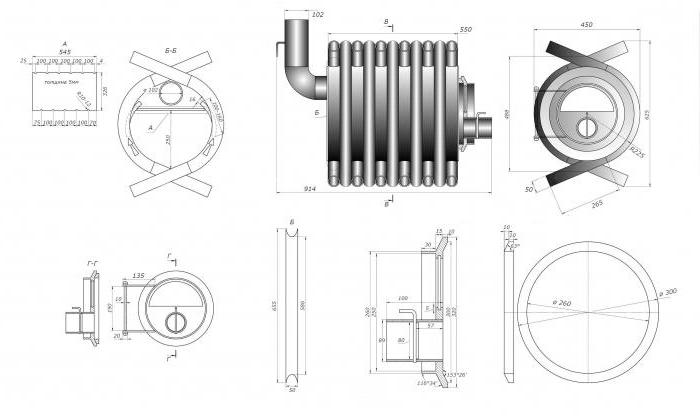

In order for the manufacture of the described design of the furnace to be successful, the design of the miracle wood-burning stove should be studied by you, as well as its structure. The unit is an all-metal construction, which has a firebox and bent metal pipes adjacent to it. On the front panel there should be a door through which you will load fuel. In addition, there is a device for adjusting power. With it, it will be possible to change the combustion modes. In the furnace there must be a secondary combustion chamber and a pipe, the output for which will be used by the chimney. Miracle wood-burning stoves will work more efficiently if you properly perform the thermal insulation of the chimney. Experts advise using mineral wool for this, the thickness of which should not be less than 3 millimeters. It will be needed and a blower, through it air will flow into the furnace, it is necessary for the combustion of fuel. The master can work on the creation of an oversized ash pan, however, in the process of slow burning of waste, practically no waste will be formed. The back wall should be double, it allows you to make the operation of the unit even more efficient. Some models are equipped with a double case.

Preparation before starting work

Before you begin to manufacture a miracle wood-burning stove, you should stock up on metal pipes, the outer diameter of which should vary from 50 to 60 millimeters. It will also take sheet metal. Since the furnace will operate at a high combustion temperature, metal sheets should be used, their thickness can vary from 4 to 6 millimeters. You must stock up with a standard set of tools and a welding machine, in addition, you will need a pipe bender.

Tips for the master

In the process of making a miracle wood-burning stove, you will need to cut pipe sections that need to be bent. At the next stage, a device is manufactured with the help of which the assembly and removal of smoke will be carried out. The master will have to perform flaps for exhaust and blowing. We must not forget about the need to manufacture a door that will close the combustion chamber. A miracle wood-burning stove, the price of which can reach 20,000 rubles, must have a frame, which will consist of bent pipes. These elements are welded together, and after a partition is installed inside. You will need to install a sheet of metal in the hollow space between the pipes. The door should have a lock, and the next step will be its installation. In order for the structure to stand firmly during operation, it will be necessary to fabricate, and then weld the metal legs.

Work Methodology

When a miracle oven is made on wood with their own hands, it will be necessary to cut individual elements from the pipe, which should be 8. The length of each of them should be 1.2 meters. The pipe bender will help to bend these workpieces, giving them a radius equal to 225 millimeters. Arrange these components of the furnace will need to be staggered. To remove smoke and accumulated moisture, T-shaped devices should be made, through which smoke will rush up into the pipe, as for moisture, it will flow down. To eliminate moisture, a special faucet is installed to remove water, it is necessary to open it only for these purposes, and then close it again. Only in this way can you eliminate traction deterioration.

What to look for when making a furnace

When a homemade miracle stove is made on wood, it will be necessary to perform a special damper, it is necessary to remove smoke from the device. With this component you can adjust the intensity of the traction. For the blower, which is located on the front door, the master must make a blind shutter. In order to ensure its reliable and proper fit, you need to use a spring. The most difficult component of a homemade buleryan is the front door. It should close almost hermetically. The better it adheres to the surface of the furnace, the more efficient the entire structure will work. A miraculous wood-burning stove, the reviews of which are the most positive, should be made using the technology described in the article. Only in this way will you be able to get a device that will work efficiently and become distinguished by its durability.

Using a pipe of impressive diameter, two rings should be made, which should fit one into the other almost densely. To do this, cut pieces of 40 millimeters in an amount of 2 pieces from a pipe that has a diameter of 350 millimeters. One of the segments needs to be cut, and then deployed. Then the front side of the structure is made, and a smaller diameter ring is used. The second ring should be used when installing the door, it should be welded to a circle of sheet metal. After that, another ring is welded onto the door, which is slightly smaller than the diameter of the ring located on the front side of the device. In the gap, which is formed by the door rings, you need to lay the asbestos sealing cord, and then the shutter.

The nuances of the work

The device of a miracle wood-burning stove has been described above, your product must comply with a design that is generally accepted. In the next step, you will need to return to the bent tubes. In the first two, you need to make holes by welding injection tubes to them. These are metal elements with a diameter of 15 millimeters. Whereas the length should be equivalent to 150 millimeters. They are needed to ensure the connection of the furnace with convection elements.

Using pipes, you should weld the frame with a partition. For the last element, 6 mm sheet steel should be used. The gaps between the pipes are closed by strips of metal, and after that the back wall is welded, which will allow forming the furnace body. For accurate fitting of partition elements, metal strips and walls, cardboard blanks should first be made. For the door, it is recommended to make a special lock, which is an eccentric that strengthens the metal hinge. It is located on the wall of the structure. This device will ensure the most tight fit of the furnace and door. A miracle wood-burning stove, the greenhouse version of which is presented in the article, should have a door and hinges, the latter are made and hung at the final stage. This also applies to the legs of the stove, which should be as strong as possible.

Conclusion

Making buleryan can hardly be called a simple process, a traditional stove will be made much easier. However, high efficiency and ease of use justify the time and energy spent. Initially, however, you will have to prepare drawings of the miracle wood-burning stove, they will allow you to carry out the whole process without errors, which will become the key to the success of the work done.