Formwork is a structure consisting of many parts. Their immediate purpose is the creation of monolithic blocks. Therefore, if you are going to build a house, then that part of the foundation, which will be located above the ground, requires formwork. Let's figure out what it is, what types exist, and how to make high-quality formwork under the foundation with your own hands. Believe me, everyone who shows the due diligence can handle this.

Formwork and its types

We have already figured out that in order for the foundation to be solid and have a certain structural appearance, it is necessary to build a formwork. And now I would like to say about its types. Currently, there are only two of them: removable and non-removable. Various types of formwork systems are presented, for example, in the KRAMOS company - . Regardless of the type, the formwork should perform several simple, but at the same time very important tasks, the main of which is to perceive and hold specific pressures from concrete, while not changing its shape. The flow of concrete mixture through the structure is unacceptable, in addition, the formwork should simply and quickly be built. Let's take a closer look at its types and determine the advantages and disadvantages of each of them.

Fixed and removable formwork

It can be understood from the name that after installation, the structure becomes an integral part of the foundation of the building. Formworks of this kind are constructions made from improvised materials. They are easy and quick to install. As the material used chipboard, fiberboard or metal frame. In some cases, it makes sense to use expanded polystyrene. We will talk about this a bit later. There are similar solutions, for example, a columnar foundation made of metal or asbestos pipes. Their diameter ranges from 150-200 millimeters. The obvious advantage is durability. This is especially true in cases where a columnar foundation and concrete products are used. In addition, such formwork is the lack of additional land work, as well as the need to install auxiliary supports and struts. As for the removable structures, then there is nothing special to talk about. After pouring the foundation and its formation, the formwork is dismantled, and boards or plywood can be used in any other business.

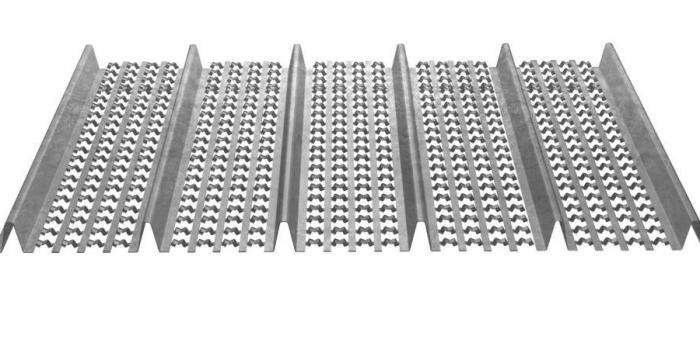

Metal structures: advantages and disadvantages

One of the most expensive materials that can be used to make formwork is iron. Most often, sheets with a thickness of several millimeters are used, which is quite enough for the perception of efforts from the foundation. I would immediately like to say about the merits of such a decision. Firstly, it is an opportunity to bend a steel sheet as you like. Thanks to this, it is possible to adapt to the desired shape of the foundation. Secondly, this is the best waterproofing you can think of for your foundation. Another important point - it is possible to weld the foundation reinforcement to the frame. From this, the strength of the structure increases several times. But for this you need to use a monolithic or strip foundation. As for the shortcomings, it is only one - the cost.

Fixed formwork made of polystyrene foam and reinforced concrete

The first thing I would like to say about reinforced concrete products. Such a solution is slightly cheaper than using steel sheets, but the price of concrete slabs is not so small, so the costs will be tangible. However, due to the possibility of changing the thickness of reinforced concrete products, you can reduce the consumption of concrete on the foundation, therefore, save a little. But here the problem is this: firstly, the plates are very heavy, and secondly, it is necessary to use additional struts, since the products are not monolithic. As for a material such as polystyrene foam, it has been used as a formwork not so long ago, but has already gained great popularity because of its practicality. The main advantages are ease of assembly. The blocks are quite simply attached to the armature, and among themselves are held together by metal brackets. This solution is good because, thanks to the unique design of monolithic blocks, the foundation is obtained not only perfectly smooth, but also of high quality (good heat and waterproofing).

What to use under the strip foundation?

Tape foundation to this day is considered one of the most relevant methods of obtaining the foundation for the future building. The principle here is extremely simple. There is a sand cushion, a prepared screed is poured onto it and a frame of reinforcement is formed. Only after this is concrete poured. But what is the best formwork to use? Almost any solution is suitable here, for example, a structure made of polystyrene foam, metal, reinforced concrete, etc. In some cases, you can not use anything at all, just dig a trench. But it is strongly discouraged to do so, as the consequences are possible, and the most unpredictable ones. According to statistics, most often tape formwork is wooden. This is mainly due to the low cost of its manufacture, and the installation itself is pretty fast.

Classic wood formwork

Despite the fact that today there are newer and unique materials in terms of their technical characteristics, the majority prefers wooden structures. This is due to many factors. The first is the price. Today it is possible to rent the formwork, and a month later to return it back. But even if you just buy boards, you are unlikely to lose anything, because they can be used in the future. For example, you can put the floor in the same house. Another important parameter, because of which it is worth giving preference to this particular material, is practicality. If something sticks out somewhere or, conversely, there is not enough piece of the product, then this is very easily solved with a saw or a hammer with nails. For example, plywood for formwork is used on floors. It is not only inexpensive, but also very reliable.

Do-it-yourself formwork

All work takes place in several stages. Let's start from the very first. We need to complete all the land work. After calculating the load on the structure, get down to business. It is recommended to leave about 1-2 centimeters of space between the formwork and the foundation. This is for easier installation. Subsequently, the void is covered with earth. It is necessary to fill the trench with sand (sand cushion). Next comes a concrete screed, which is necessary to reduce material loss during pouring. If it is planned to reinforce the structure with rods, then they must be driven into the ground at this stage. In the second stage we will build the formwork. To begin with, we customize all the elements, and only then we proceed directly to the construction.

Marking, strengthening and installation

First you need to do the markup. After that, where the corners of the formwork should be, we hammer in small pegs (wooden). They are needed directly for fixing the structure. Further, according to pre-calculated sizes, shields are selected. Here, monolithic formwork is more preferable, since it is easier to install due to design features. The shield with nails, screws and screws is attached to the stakes. So, in fact, the frame is formed. But that is not all. With a significant length of formwork or large volumes of poured concrete, it is necessary to strengthen the structure. This is done with the help of spacers, which are set in increments of 70-90 centimeters. There is another solution: to tighten the structure with studs, but in this case, further use of the shield in the household will be difficult, as there will be holes in the boards. During installation, you must carefully monitor the vertical structure, for which you need to use the building level. All cracks must be closed. For this, practically any improvised means are suitable. If the distance between the two formwork elements is more than 4 mm, then this is an obvious leakage of concrete.

How to make a calculation?

Before the formwork of the house will be erected, it must be calculated. This is done to determine the critical parameters. As an example, consider the most common wooden formwork. So, a standard board has a length of 6 meters, a thickness of 25 millimeters and a width of 100-150 mm. The perimeter of the foundation must be divided by 6, that is, the length of the board, and the height - by width. The obtained results need to be multiplied, and you will get the finished number. On average, about 42 boards 100 mm wide are consumed per cubic meter. Based on this, you will have to spend about 5-6 thousand rubles per cubic meter. To all this, it is necessary to add the price of a bar for struts and strengthening the structure. All together will cost about 10,000 rubles. For example, non-removable polystyrene formwork must be designed by a specialist. Here the foundation plan is taken into account. If there are many complex nodes, then the cost will be approximately the same as when buying steel sheets. In addition to the foregoing, one must not forget to take into account the cost of consumables: nails, screws, fittings, spacers, etc.

Need to get rounded shapes? Not a problem

In some cases, rounding just can not do, and this is an obvious fact. As a material, a metal shield or a wooden non-inventory board can be used. If you want to build a column, then the first step is to create a L-shape from the mounting corners. Do not forget to fix them among themselves. But everything is much more complicated if it is necessary to obtain not a square, but a round shape. Here it is best to use boards. It is necessary to recruit them according to the principle of a barrel. The fact is that the formwork of the columns must withstand large specific loads, so it is recommended to make a fixed structure. To do this, after every 50-80 centimeters, you must use ties and pegs to strengthen. In some cases, it makes sense to look for a finished frame. If you are lucky, then you will find the right diameter and you can save a lot, not only money, but also nerves.

What other materials are suitable?

Of course, not only the board can be used, but in some cases this is the only right decision. If you need to build a formwork of small strength, but rounded, use plastic. A great solution for building a gazebo, but no more. The material bends well, especially if it is slightly heated. But, again, the strength here is minimal. For example, plywood for formwork is also a good solution, but all this is good if it is additionally strengthened by a board. Its strength is slightly higher than that of plastic, but still for serious purposes this is far from the best solution. As for metal sheets, they can be used almost everywhere. But the formwork of metal ceilings hardly makes sense. The loads here are small, and the volume of the foundation too. But the cost of the sheet will unpleasantly surprise you. If you take metal sheets, use them for columns or where very strong material is required.

A few important points

So we have examined how to make formwork, as well as what materials are best suited for the implementation of a particular goal. As you can see, there is nothing complicated, the main thing is to follow a few important rules. Firstly, it is worth paying enough attention to the strength of the structure, and secondly, we must not forget about the verticality of the structure, since this is of great importance. For example, when formwork of columns is created in order to make the structure more even, it makes sense to dig boards a little into the ground. So you add strength and avoid skewing while pouring concrete. If you do not work with external walls, then it is not necessary to use metal sheets, this is simply irrational. Most often, the formwork of floors is created from plywood or boards, it is really profitable and advisable.

Conclusion

Now you know what formwork is. This is what any building construction is complete without. Despite the fact that there is a huge selection of materials, the construction principle remains the same.

Well, that’s all that can be said about how to make the formwork with your own hands from various materials. If you are going to live in this house, then be careful at all stages. You probably do not want to later “enjoy” the curved wall or damp corners due to the fact that the verticality was not observed, or the wrong material was used.