Among the wide range of fasteners offered on the market by manufacturers, one of the most popular is wing nuts. Such fasteners are especially common in the construction field, and are also widely used in mechanical engineering. Also, this type of fastener is known as a coupling nut. This article is dedicated to her.

Design features

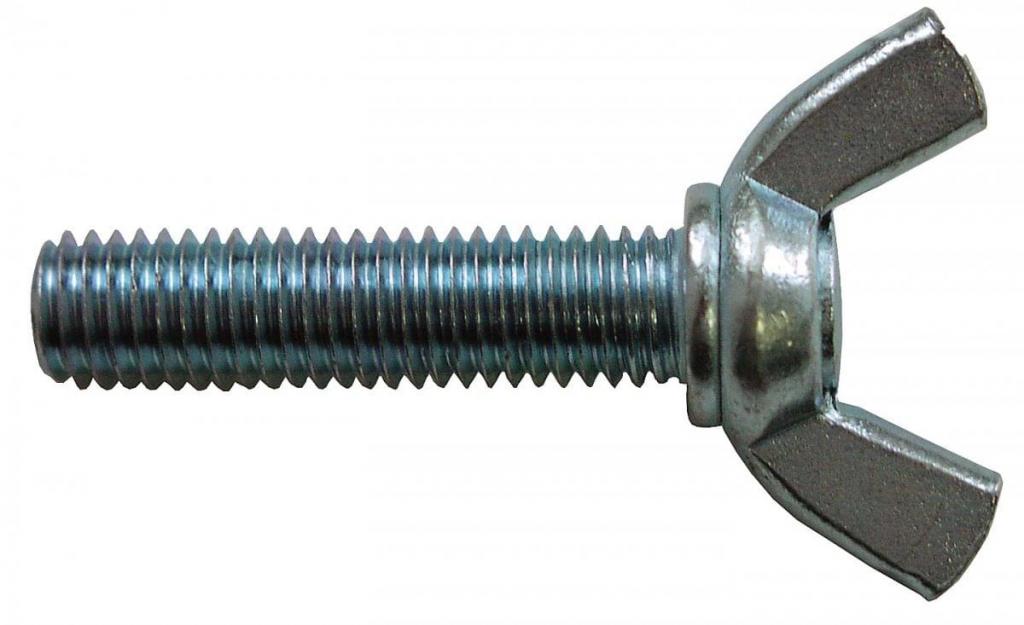

The wing nut has special petals or antennae, designed to twist or unscrew it without using any additional tool. In other words, you can install or remove this hardware manually. The rest of the wing nuts, like the rest, have an internal thread.

The use of such nuts is justified for the production of compounds which, due to the particularities of operation, are subjected to frequent assembly and disassembly.

Varieties of coupling nuts

Wing nuts have a diverse classification. This type of fastener is divided into the following types:

- In the shape of the antennae, the nuts are American and German types. American nuts are produced by cold stamping, and they are rectangular on the antennae. The German type of nut has rounded petals and is forged or cast. This type, although more expensive due to the manufacturing method, is also more convenient to use.

- According to the material used. For their manufacture, the most common are steel, brass, cast iron alloys. American nuts are made of steel and brass. German wing nuts, given the method of their production, are made of cast iron.

- In diameter. The diameter of the tie nuts can be measured both on the ears and without them. The most common fasteners have a diameter of 100, 70, 85 mm.

- On withstanding load. The permissible load on nuts of this type varies from a couple of kilograms to several tens of tons. This explains their use in engineering and construction.

- By strength class. This parameter will be determined by the environment where this type of fastener is planned to be used.

- By design features. There are nuts with and without support pad. The presence of a support pad increases the rigidity of the nut. Also, at the very base of the nut, it can have a chamfer that allows it to be easily screwed onto the coupling bolt without jamming. In addition, the nut flaps may have special holes for sealing.

GOST for wing nuts

The design and dimensions of the nuts of this type used in practice must comply with GOST 3032-76. According to this document, lamb-type fasteners with internal thread diameters from M3 to M24 are allowed for release. The most popular is the fastener with M6 thread. The manufacture of fasteners with M14 and M20 threads is not recommended by this GOST. In this GOST, all parameters for the corresponding fasteners are indicated.

According to the provisions of GOST, nuts can have a large and small thread pitch. A large thread pitch is in the range of 0.5–3 mm. For fasteners with M6 thread, it is 1 mm. A small step has only fasteners with threads from M8 to M24.

You can familiarize yourself with the design of this type of fastener in detail by studying GOST 3032-76.

Foreign analogues

An analogue of fasteners manufactured in Russia according to GOST 3032–76 is DIN315 standard fasteners manufactured in Germany.

The key dimensions of foreign nuts to DIN 315 are:

- d - determine the thread;

- h is the height of the nut to the upper edge of the "ears";

- e is the width with the "ears".

Conclusion

As practice shows, the production of fasteners of such a complex shape requires the availability of appropriate and at the same time expensive equipment. In addition, a significant drawback of such nuts is the low strength of the formed fasteners. For reliable connections using wing nuts, careful preliminary calculations are required.