Artificial materials in the form of synthetic plastics have successfully replaced solid products in many areas. If previously metal and stone structures demonstrated unique qualities of density and rigidity of the structure, today composite elements repeat these properties. But the texture and overall aesthetic qualities of granite or marble remain unattainable, which determines their demand even against the background of the development of artificial substitutes. At the same time, they do not lose their relevance and technologies that allow efficient processing of solid-state material. On the market, a stone cutting machine is presented in many design options, which allows you to choose the best model for each case.

Features of Stone Cutting Machine

Thanks to the ability to adjust the cutting parameters, modern units of this type can cope with a wide range of building materials. First of all, it is a natural stone. Universal machines allow it to be processed in several configurations of a profile cut. The operator can adjust the inclination of the cutting element and change its height, which allows you to get a product with a non-standard shape at the output. The latest modifications provide special modes for working with templates, the use of which facilitates the tasks of the user. In addition, the universal machine for cutting tiles, stone and concrete can also be used in working with soft materials. If solid-state workpieces are characterized by high rigidity and density, making processing difficult, then soft-body building materials assume different cutting nuances. In particular, a coarse and high-performance machine will not allow you to get an accurate and accurate cut. For a stone, this is not a problem, since in the future grinding operations will still follow, but for plastics and wood it is advisable to initially use the delicate processing mode.

Types of equipment

Two main categories of machines designed for cutting stone can be distinguished. These are units operating on abrasives and traditional equipment with circular saws. The first group can include sandblasting and waterjet machines that provide high precision processing coupled with productivity. Sandblasting units use an air stream as a working medium, which is complemented by a sand base. The stream supplied under high pressure also carries out the cutting of the material. A waterjet technique works according to a similar principle, but in this case, an aqueous abrasive carrier is used instead of air. On diamond blades, a stone cutting machine usually runs with a supply of water that cools the functional mechanisms. The most advanced technique of this type is a laser, which is characterized by high precision cutting without mechanical impact.

Main characteristics of machines

From the point of view of the efficiency of the operation process, it is important to take into account the speed of cutting, the acceptable parameters of the workpiece, machine power indicators, the accuracy of the positioning of the working body and ergonomics. Traditional disk cutters are capable of working with a depth of about 10 cm, and the length can be 50 cm. As for the power of the power unit, it is on average 2-3 kW. In terms of energy consumption, laser cutting machines for natural stone show themselves well, which also have a high processing speed. Hydroabrasive models are also advantageous due to their low energy consumption and the ability to cut material up to 30 cm thick. But in the convenience of maintenance, such machines lose to sandblasting machines because of the need to bring a source with clean water.

Characteristics of the cutting element

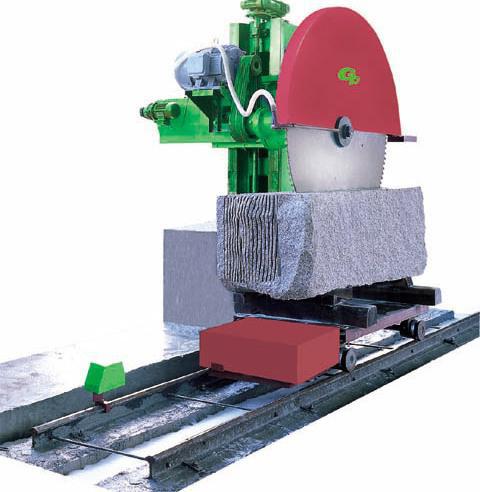

In the case of laser and abrasive aggregates, working elements are absent in some way, and direct cutting is carried out as a result of the influence of the formed working medium. But in equipping diamond disk machines, there is a wide variety of functional elements, the parameters of which, by the way, determine the size and quality of the cut. A typical stone cutting machine of this type works with disks whose diameter is on average 35 cm. This is the optimal size if you need to form slabs from a solid array. Sometimes those who wish to acquire such equipment purchase discs with a margin, but this is an irrational decision. In order to save energy, it is advisable to use a snap that best matches the parameters of the workpiece.

Machine Automation

A large part of modern stone processing machines receives automatic control systems. Actually, the lowest level of automation is represented by units with simple control relays for a narrow set of functions. In the latest versions, manufacturers seek to use already programmable logic controllers, when working with which the operator's tasks are minimized. Based on the algorithms embedded in the system, the stone cutting machine performs a full cycle of operations. Advanced technologies demonstrate the capabilities of machine tools of a different level. These are CNC models that independently calculate cutting parameters based on the tasks set by the operator. Such an aggregate is also capable of working with computer models and graphs.

Homemade stone cutting machine

The most affordable option for implementing such an idea is a disk unit. It can be made of three main components - power filling, frame frame and directly the working element in the form of a disk, which is purchased in the store as a consumable. The operation of the mechanisms is provided by the engine. A single-phase unit with a power of about 750 watts is suitable. Its equipment will also include a shaft and a hub, which should be modified for an optimal fit in the future countertop. The platform should be made of three-millimeter steel sheets, which will make the stone cutting machine more reliable. With your own hands you can assemble the body for the tank with water. In the future, it should be suspended above the structure - this will be the same cooling system for overheating working bodies.

Conclusion

Stone is one of the most difficult materials to process. Much depends on the particular breed, but on the whole in terms of characteristics it is comparable to hard metals. Nevertheless, a properly selected stone cutting machine will allow you to cope with the cutting tasks without unnecessary problems. For the most complex operations, it is recommended to purchase models with automatic control systems. They will provide high precision machining with minimal cost and at high speed. If we are talking about the irregular implementation of such events, then it makes sense to limit ourselves to the use of a home-made unit.