The construction tool segment for working with hardware is actively developing towards increasing independence from manual effort. Wrenches have long acquired battery and network electric drives, but such models have a number of drawbacks, mostly related to low autonomy. As a boundary option between manual and electrical devices, a hydraulic wrench is proposed, which relieves the operator of physical stress when twisting and unscrewing the fasteners.

Tool Design Features

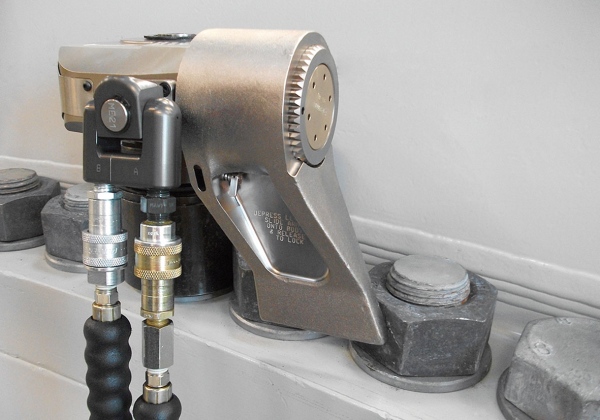

The basic components of this wrench include a housing, a hinge system, a reaction arm and a grip for gripping. But this mechanics does not work without a drive, which is a hydraulic station. It can have a different design, but a sleeve of high pressure is used as a means of switching. For the convenience of pairing a hydraulic wrench with a force transmitter, quick-release coupling halves and other devices for universal connection can be used. A double-acting hydraulic cylinder block is also located inside the housing. In the process, its piston mates with a ratchet system, which, in turn, consists of a power dog, levers and a power wheel with a planetary gear. The fluid flows through the articulated ligament into the hydraulic cylinder, creating the necessary pressure, which passes into the force.

Principle of operation

This type of wrench acts on the principle of force conversion, which develops in a hydraulic cylinder under pressure. As you move from one functional unit of the tool to another, a torque is created that acts on the grip mechanism of the nut. But for this, sufficient translational movement from the connected station must be ensured. It is important to note the features of the hydraulic cassette wrench, which is characterized by versatility in terms of the possibilities of working with fasteners of different sizes. It is called cassette because of the possibility of changing inserts to capture the heads of hardware. The ratchet mechanism transfers the force to the key at a certain angle and force. However, the quality of the coupling will to a large extent depend on how much a particular cassette matches the parameters of the target fastener.

Tool varieties

Hydraulic actuated wrenches are distinguished by two criteria: impact and purpose. In particular, hydraulic impact wrenches during the application of force make vibration shocks - impulses. This allows you to cope with firmly planted fasteners - including rusted and large-format ones. Accordingly, shock-free models are relieved of such a function, but its absence cannot be called a drawback, since the more compact size and uniform distribution of effort at low speeds makes such wrenches optimal in relation to standard operations.

According to their purpose, end and flange models can be divided. In the first case, we are talking about a tool designed to tighten bolts with a controlled moment. By the way, the tightening torque of a hydraulic end wrench can be about 60,000 Nm. For flanged or low-profile models, the tightening torque when working with threaded connections does not exceed 50,000 Nm. These are compact and lightweight wrenches that are more often used when servicing hardware on high heels.

Main characteristics

Technical and operational parameters are very important in choosing a tool with a complex structure. In this case, attention is drawn to the following characteristics:

- Tightening torque - an average of 40,000 to 60,000 Nm. However, there are also low-level models of low productivity - up to 8000 Nm.

- The accuracy of twisting - the error is about 2-3%.

- The mass of the structure is from 0.5 to 4 kg. An important parameter of a hydraulic screwdriver, especially when threading, since the tool has to be held on weight for a long time.

- Rotation of the working part - as a rule, the rotation works 360 ° due to the articulated connection to the housing.

The quality of the workflow will depend on additional functionality. For example, it can be wide adjusting capabilities, the presence of a fuse, a valve for adjusting the pressure, etc.

Popular Tool Manufacturers

With all its advantages, in Russia wrenches with hydraulic cylinders are less popular than electrical counterparts. Among domestic manufacturers, one can distinguish Nordman enterprises with Torc and TTZ lines, as well as Hydravlik Pro, under whose brand a good model for household needs SPT615130010 is produced. As for foreign manufacturers, in this category Jonnesway, Metabo, Enerpac, Abac and FUBAG offer their developments. These are companies that are closely involved in the design and manufacture of engineering power equipment - the same hydraulic and compressor stations. However, niche developers of hand tools are also represented in the segment. For example, a hydraulic wrench from Stanley IW 16 with a maximum pressure of up to 175 bar shows an example of optimal interaction between production equipment and a compact device for performing small-format manual operations.

Conclusion

Hydraulic mechanisms are often used as drive systems to support the functions of various equipment or tools that do not require connecting to mains or batteries. As the power system can be used and pumping stations, and compressor units. Of course, their introduction into the working infrastructure complicates organizational activities. And with the example of a hydraulic wrench, this is especially noticeable, since such tools require the execution of low-cost operations on resources. Nevertheless, in many areas of industry, construction and production, such wrenches are simply irreplaceable. It is for reasons of versatility and the possibility of working with fasteners of various types in conditions of separation from the main energy supply sources.