Flanged ball valves are widely used in many fields. For example, it can be seen on pipelines used in the gas, oil, chemical, food industries, as well as in other areas. Steel ball flange valve is used in the transportation of petroleum products, hydrocarbons, liquids and gases as shutoff valves. In addition, this device has found wide application in such fields as ventilation, water and gas supply. It is also actively used in agriculture and shipbuilding. This device is designed to block the flow or for its release into the pipe. The flange ball valve is also used in steam supply, as well as when working in temperature conditions up to 250 degrees Celsius.

It cannot be used for throttling. This type of taps cannot be used to adjust the flow rate of the shut-off device. This is due to the fact that such devices have only two states: completely closed or open. These devices use a ball as a locking part, which is why they got their name. Cranes are made of three types of materials, the choice of which depends on the intended working environment. Stainless steel is designed to function in aggressive; Article 20 is designed to work in normal conditions; 09G2S - for sulfuric performance. It is unacceptable to use a spherical flange valve in pipelines, where there is a possibility of a flow of crude liquids with solid impurities. This can cause the undercarriage to wear and then leaks. You should not use this type of device as a shutoff for silty, viscous or viscous liquids. There is a rather high risk of sediment, which can adversely affect the useful life of the device. The standards for the use of this type of equipment prescribed in the instructions should be strictly observed. It is impossible to increase the load on the crane; it should not be used when partially opened as a flow force regulator.

Steel

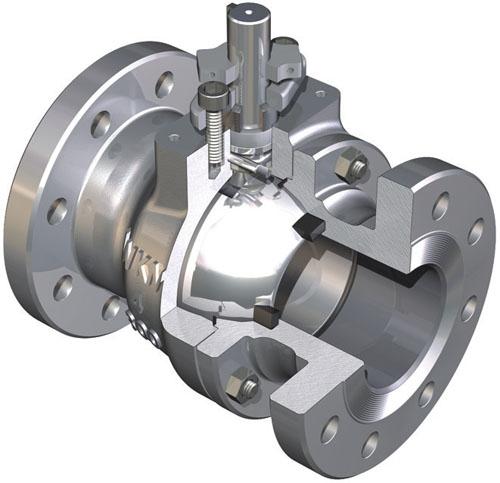

ball flanged

crane can have certain design features. The first type has a locking part that is not connected to the spindle. In relation to it, the ball element moves freely. When the pressure of the medium acts on the ball from the inlet side, it is pressed against the sealing element, providing sealing and blocking the flow. This design can be used with a diameter not exceeding two hundred millimeters. Such a choice of sizes allows to reduce the load that is created by the locking element in relation to the sealing ring.

Flange ball valve of the second type involves finding the ball on the supports. The locking product in such structures is mounted due to the presence of an axial protrusion. When pressure arises from the saddle side, a pressure is applied to the support of a spherical shape. This design of the ball valve allows you to reduce the force required to lock or unlock it.