Machines for processing wooden billets today are used not only in industries and in professional workshops. At home, a small turning unit allows you to accurately perform complex pieces of furniture, utensils, decorative accessories, carved jewelry, etc. For such tasks, the domestic Enkor Corvette-71 machine is optimal, the dimensions of which are designed for operation in a workshop, hozblok or garage .

Machine design

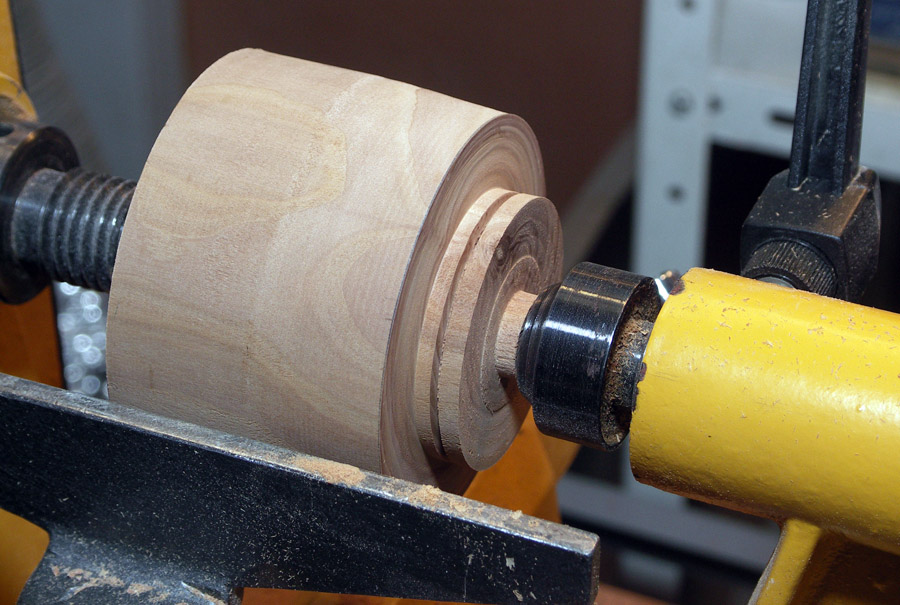

The model is a turning electric wood processing machine. At the heart of the unit is a metal bed, which assumes a desktop installation with the ability to adjust the height and position of the guides. Among the main assembly parts of the Corvette 71 machine are the following:

- Front headstock of the machine.

- Front spindle

- Tool post.

- Support for tool holder.

- Handle of the tool holder support.

- Turning faceplate.

- The tailstock of the tailstock.

- The central part of the tailstock.

- The locking handle of the rear pintles.

- Locking handle of the tailstock.

- Tailstock.

- Flywheel to move the pintles.

- Magnetic starter drive.

- Electric motor

The design of the machine allows you to process workpieces with a diameter of up to 250 mm and a length of up to 455 mm. At the same time, work with metal, stone, asbestos-cement and rubber products is not allowed. Also, restrictions regarding the operating mode itself should be considered. Unit capacities are not designed for continuous processing format.

Specifications

The power potential and technical performance of the model are designed for processing small-sized workpieces, which corresponds to many hand tools. Another thing is that the design and guides with clamps facilitate work operations on the Corvette 71 machine. The turning unit in this modification has the following characteristics:

- Engine power - 370 watts.

- Type of motor - asynchronous electric.

- The required voltage in the network is 220 V.

- Number of speeds - 5.

- The frequency of the machine spindle is from 760 to 3150 rpm.

- Diameter of processing - up to 250 mm.

- The length of the workpiece is up to 455 mm.

- The distance between the gripping centers of the part is 420 mm.

- The dimensions of the machine are 83 x 30 x 43 cm.

- The mass of the structure is 38 kg.

Additional functionality

The owner of the machine receives several adjustment options, which are implemented thanks to the spindle and belt drive. This allows you to adjust the processing speed to the desired frequency with an emphasis on the characteristics of the workpiece and the parameters of mechanical stress. There are several safety add-ons in the Corvette-71 operating system, some of which are related to electrical engineering. For example, in case of overloads in the network, a special protection unit such as RAM is provided, and spontaneous start of the machine after a power outage prevents the magnetic starter. As for the functions and processing modes, at the basic level, it is possible to solve grinding and polishing problems, but with the proper skills of working with turning equipment, the user will be able to perform high-precision cutting operations.

Machine manual

You can start connecting and further operating the machine only after it has been installed reliably on a workbench or other stable surface. Connection is carried out only to the 220 V socket having grounding. Small voltage deviations of 10-20 V are allowed, but only in the form of a temporary error at the time of network differences.

Turning on the Corvette-71 lathe is done through the green button of the starter. From this point on, the unit cannot be left unattended until it is turned off by the red button. Adjustment of the processing mode is carried out through the headstock mounting bolt. When it is weakened, it will be possible to move the platform with the engine, change the parameters of the position of the workpiece and the speed of rotation of the spindle. The tailstock is shifted by performing regulatory manipulations with the locking handle. She also changes position with respect to the bed. The workpiece is installed tightly, but so that there remains the possibility of accurate mechanical action by the tool holder. The ability to cut is assessed visually - after fixing the part, it is enough to scroll it around its axis, checking the contact points with the processing equipment.

Work Safety

During the organization of work with the unit and in the process of direct processing of materials, the following safety rules recommended by the equipment manufacturer should be followed

- Always check the condition of protective devices and equipment.

- Unnecessarily, tools, workpieces and other items with materials should not be near the machine.

- The room itself, where Corvette 71 & amp; raquo; is used, should have good lighting, a ventilation system and fire safety equipment.

- The operator must have the appropriate equipment - an apron, gloves, non-slip shoes, a respirator and goggles.

- In the process, it is forbidden to reach through the machine, trying to get the right part. Operator movements must not potentially upset his balance and entail additional risks of personal injury.

- The machine can only be used for its intended purpose - this applies to the processing materials, their parameters and the operations performed.

Machine Maintenance

Regularly, and especially after each working session, it is necessary to clean the machine from dirt and dust. It is desirable that in the process of operation a dust collector pipe is brought to the equipment, which minimizes the accumulation of wood chips on the machine and in the operating area. In relation to the machine, the greatest attention during care should be given to the engine and the surfaces of the headstock, where the largest amounts of dust accumulate. It is recommended to cover the Corvette 71 machine with car wax, which will contribute to the smooth movement of the caliper and tailstock. Threaded connections and handles should be coated with machine oil and special grease to ensure stability. A thorough inspection with preventive maintenance measures is carried out at least once every six months, subject to regular use of equipment. This applies to cleaning, flushing, lubricating and adjusting operations. If problems are found, it is necessary to proceed with technical recovery operations, if possible without the participation of specialists.

Possible problems and their correction

In addition to structural malfunctions and damage that are solved by replacing individual elements, it is necessary to prepare for the following problems with the electric motor:

- The power unit does not start. It is more likely to have problems with wiring, insufficient power supply characteristics and low voltage. Directly "Corvette-71" is checked in parts of the stator, circuit breaker and fuse.

- The engine does not work at full power. Usually this problem is observed in cases of low voltage or cable damage - you should check the winding and test the network with a multimeter.

- The engine gets very hot. Also, various kinds of malfunctions of the mains and the connecting cord are not excluded, but there may be malfunctions of the interrupter. In addition, thermal and physical overloads are quite possible if the machine operates for a long time at peak capacities.

Positive feedback about the machine

Owners of the model characterize it as a light, reliable and easy-to-use machine, optimal for domestic use. The high build quality, in particular, is evidenced by the tight bow of the cast bed and tailstock without play. In the work process, Enkor Corvette 71 also shows itself from the best sides - no beating, vibration, or even noise characteristic of such machines is noted. As for the restrictions on the load, many reviews indicate the ability of the unit to withstand hours of processing sessions, although the manufacturer recommends making 15-minute pauses every half hour.

Negative reviews about the machine

Typically, lathe models of machines are appreciated not only for lightness and small size, but also for ergonomics when performing physical manipulations. In this case, opinions about ergonomics are ambiguous. So, many owners criticize the performance of the Corvette-71 plastic handles. Reviews note not only a poorly thought out configuration of their placement, but also structural weakness. The same applies to the pressure washers, on which the position of the tailstock in the movable stop depends. It happens that the loosening of the bolts leads to a skew of the clamp, as a result of which the washer shifts and deforms with time.

Conclusion

The company "Encore" is considered one of the leading developers of Russian processing machines, designed including for the domestic use segment. However, it still manages to withstand fierce competition with foreign counterparts only in the price parameter. In some ways, the Corvette-71 wood lathe could be an exception to this rule, since in its functional and structural basis a serious step was taken towards development. Especially when you consider the calculation of operation at home. And yet, the cost is about 18-20 thousand rubles. can not be called low for models of this level. In addition, it is worth focusing on minor flaws, the presence of which is obviously explained by the desire of the creators to save. On the other hand, the basic level of quality of the functions performed in the eyes of the ordinary undemanding master leaves such shortcomings in the background. According to the general characteristics of woodworking, this unit completely agrees with semi-professional models, if you do not discount the power potential.