Jet furnaces became popular not so long ago. In addition, not everyone knows about the advantages of such a heating system. It is worth noting that they are classified as energy-efficient furnaces. Such heating systems got their name thanks to reactive processes based precisely on heat transfer at significant temperature differences. In this case, thrust occurs in the jet furnace. A similar phenomenon is described in the course of basic physics. And this is thanks to working without failures.

The design of the rocket

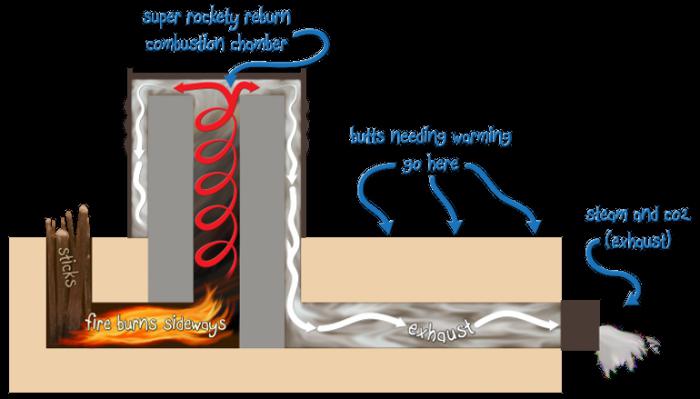

A jet furnace is always equipped with a knee whose angle is not more than ninety degrees. This is the main feature of this model. In other words, the chimney in relation to the bottom of the furnace is located at an acute or right angle. In this case, the furnace must be equipped with an air duct. It is usually placed through a wall with a firebox.

The advantages of jet furnaces and the principle of their operation

Before a do-it-yourself jet stove is built, it is worth understanding the principle of its action and assessing the merits. The main difference of this design is that the concentration of temperature occurs precisely in the air stream, which is constantly in motion, and not in the furnace. In this case, a continuous thrust occurs in the knee - in the place of heating. Air with oxygen is supplied through the duct for combustion, and in the furnace it receives a sufficient amount of thermal energy. In this case, ordinary wood can be used as fuel. In places where a temperature difference is observed, thermal energy is given off. Thus, traction is constantly maintained.

A continuous jet furnace does not require special adjustment of the air supply. Indeed, the natural balance of all processes provides the necessary traction in strength. In other words, the one that is required to maintain the desired temperature in the furnace. As for the exhaust of all exhaust gases, this process also proceeds naturally, with the help of the pressure of already warmed air. It is for this reason that a reactive furnace is built with a low chimney.

The first stage of construction: only pure flows

A jet furnace, the circuit of which is not so complicated, consists of several important elements. One of them is the knee. For its manufacture, you can weld two pipes at right angles. In diameter, these parts must be at least fifteen centimeters. In this case, a ratio of 1 to 2 must be observed. As a result, an already finished firebox with a chimney pipe should be obtained. The short part of the knee should be horizontal, and the long part should be vertical. If you make a fire in the pipe, then the heat will go up.

To organize the supply of secondary air, you can use one of the primitive options. For this, a metal sheet should be installed on the brackets inside the furnace. This will allow you to move away from the duct. But the air that will pass through it, in the end will always be in the corner of the knee. This is what allows us to call it secondary. In order to make the reactive oven, made by hand, more functional, you can weld the legs to the finished device, and install the grid for the pan on the upper channel.

The second stage of construction: a rocket stove

The basis is the structure built in the first stage. To it you need to add another important element - a horizontal section. The rectangular section of the channels is much more convenient in terms of operation than pipes. A jet furnace, the drawings of which allow you to more accurately imagine the entire structure, can have a different structure. In this case, the duct can be positioned arbitrarily. However, it is worth observing one of the rules. In any case, air must pass through the duct. To do this, you can use along the bottom wall of the plate on the ribs, parallel side walls of the loading hatch or "brush".

After that, the steel chimney joins the elbow. Then you can install the roof. It is very difficult to describe exactly this design. After all, all kinds of improvised materials are usually used for its manufacture. Often a reactive furnace is made from a gas cylinder. The main thing is that the principle of stream formation should be implemented.

Third construction phase: vertical heat exchanger design

This idea is to create a steel heat exchanger with sufficiently thick walls precisely on the path of heat flux. The element built in the second stage must be increased in size. To do this, you need to install an empty tank instead of a pipe going vertically, which will be used for dry heat transfer. In this case, a gas bottle is ideal.

The jet furnace must be constructed so that the horizontal element is aligned with the chimney duct. This moment is very important. In this case, the firebox - a horizontal element - can be made in several versions. It can be a box, a pipe or a stove case. If this part has sufficient dimensions, then it can be used as a preliminary heat exchanger.

In order for the jet furnace, the circuit of which is presented above, to burn continuously for up to 4 hours, it is necessary to increase the size of the fuel compartment. In height, this element can be up to 60 centimeters. In this case, the loading of logs should be vertical. In this situation, the combustion of raw materials will occur in the lower part. Logs will gradually burn and under their own weight fall below.

The Shirokova reactive furnace is quite simple in design. Primary air is usually supplied through a door located in the area of the furnace, and secondary air through a channel or an opening on the knee.

The fourth stage of construction: installation of the injector

At this stage, it is necessary to equip the product with a separate channel, due to which oxygen will be supplied at the stage of burning the fuel. This requires a pipe with a diameter of 1.2-1.5 centimeters, preferably curved in the form of the channel itself, obtained from individual structural elements. On the one hand, you should install a plug and make in one of the walls up to eight holes with a diameter of six millimeters. A section with holes made in length should be no more than 100 millimeters. The finished pipe must be installed so that it passes through the entire system. In this case, the edge with the plug should reach the place where the flame still reaches. As for the open side, it should be in the cold part of the structure and have an influx of fresh air. When heated, the metal will create the necessary traction.

The fifth stage of construction: installation of a turbocharger

The jet furnace is not yet finished at this stage. An air pump should be connected to the injector. For these purposes, you can use a regular old vacuum cleaner. In this case, the injector must have sufficient throughput. After the pump is turned on, not only will the flow of fresh air increase, but additional pressure will also be created . At the same time, the thrust will increase in proportion to the applied power. This process will be provided by increasing the temperature in the heat exchanger.

It is worth noting that a similar method has been known for a long time. It was used by masters. At the same time, the functions of the air pump were performed by a special blacksmith fur.

Instead of a conclusion

If a reactive furnace is of interest to you, and you decide to install it in a house, remember a few basic rules. First of all, every detail in the system should be harmonious. Each piece of construction must be balanced. Otherwise, overheating will occur, which will ultimately lead to the burning of metal parts. It is worth noting that you need to install a jet furnace not near the wall, but at some distance from it. So it will more effectively heat the room.