Pumping equipment occupies an important place in the organization of water supply and heating systems. At a basic level, using this technique, fluid is pumped from a source to a place of consumption. However, with the optimization and rationalization of the processes of transporting liquid media, the task of precisely maintaining a sufficient speed of movement in the delivery circuit was singled out. The circulating pump device based on an electric motor with a rotor is also oriented towards its execution.

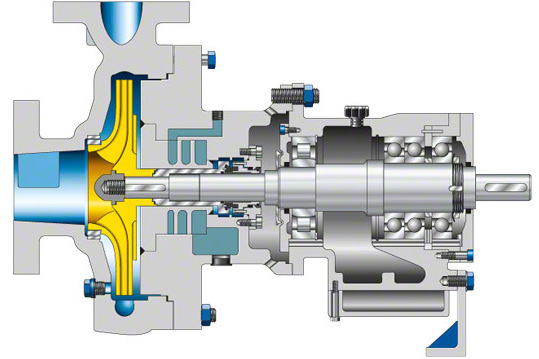

Unit design

The housing is mainly made on a monoblock basis, due to which the degree of tightness is increased, but the possibilities for carrying out repair measures are also reduced. The operation of the hydraulic infrastructure is provided by an electric motor with an output for connecting to the network (some designs allow two-way cable supply). By the way, the modern device of the circulating water pump provides for a wide range of electrical protection equipment, including load adapters with speed control, a safety block and an auto shut-off system.

Also, the stator, the impeller, the shaft, the flange components, the terminal box, the pipes for connecting underwater communications, etc. are included in the pump base device. This is the working group on which most pumps designed for heating systems are based. Particular attention should be paid to auxiliary devices of the circulation pump. Repair operations are usually associated with their replacement. This applies in particular to gaskets, thrust bearings, plugs and insulation materials. These elements have different operational resources, but at certain time intervals they deform or wear out, requiring updating.

Much of the reliability of the circulation pump and its components depends on the quality of the materials used. The case is often made of cast iron or steel alloy, although some models use high-strength plastic to reduce weight. The fittings are made of composites, rubber (synthetic rubber), thermoplastics and extruded aluminum. In the latest versions of the pumps, there is a rejection of metal rubbing elements in favor of ceramic ones. This decision affects the price tag upward, but increases the resource of the same bearing.

General principle of equipment operation

The function of the circulation pumps is different in that they do not directly participate in water intake and return operations. At least, the traditional device of the circulation pump for heating is designed to maintain a sufficient speed of movement of water in the circuit due to the impact of the impeller. At the installation point of the unit, the liquid exits at a higher pressure, which affects the flow rate. In other words, the speed mode on the approach to the impeller of the pump is converted by increasing pressure, which, at a minimum, ensures constant movement of the coolant.

It has already been noted that heating systems are the targets of a circulation pump. But can they be used in a water supply system? As in the heating circuit, such equipment may well serve as a pressure stabilizer and flow velocity. However, it is important to consider that the pressure control functions in heating and water systems differ in loads. If in the first case it is only necessary to maintain the flow, then a full supply of water, for example, on the second floor requires much more resources, for which the principle of operation of the circulation pump is not calculated. The device of some models allows the connection of an expansion tank (hydraulic tank), the presence of which can increase the pressure head, but centrifugal self-priming pumps are better able to handle water supply problems.

Conversely, not every surface centrifugal pump can be integrated into a heating system. The fact is that the medium is not only characterized by a high temperature of up to 110 ° C, but also by the presence of antifreeze in the mixtures. To service such media, special heat-resistant pipes in the heating system and pumps with acceptable characteristics of the internal surfaces that distinguish circulation systems should be used initially.

Wet Rotor Models

In this case, the place of the rotor is located in the zone of the internal coolant flow, that is, the element is located in direct contact with the medium being served. The key operational effect of this configuration is the indirect fluid lubrication that the unit carries. This determines the optimized circulation pump design with a “wet” rotor, in which there is no special infrastructure for lubricating the rubbing parts of the engine. Among the external factors of the use of such equipment, one can note a low noise level and ease of maintenance.

However, the simplification of the design of the pump has the opposite sides of operation. For example, manufacturers set strict requirements for the placement of the pump. Its body must be placed so that the rotor occupies a strictly horizontal position, otherwise the equipment will fail. Also, due to the filling sensitivity to pollution, the wet circulation pump device in some versions involves the introduction of a cleaning filter on the inlet pipe. This is due precisely to the fact that the lubricating coolant may contain small solid inclusions that adversely affect the state of the same rotor during prolonged operation. Another negative factor follows from this - a decrease in productivity up to 40%. For this reason, wet-rotor models are used only in networks with a small number of short branches.

Work models with a "dry" rotor

In this pump configuration, the rotor is isolated from the coolant duct by means of gaskets and stuffing boxes. The lubrication of movable parts is solved in a separate order with the help of technical oils. But there are also different variations of the device and the principle of operation of the circulation pump with a "dry" rotor:

- Console models. It is supposed to separate the electric motor and its working infrastructure due to a special coupling. Both parts are in different blocks, but at the same level, which excludes the possibility of their non-parallel interaction.

- Monoblock designs. Also, the engine is separated from the working part, however, everything is located in one block, which facilitates the installation and maintenance of the pump.

- Inline configuration. In fact, a modification of the console system, but with an improved implementation of connecting equipment. For this, not only a coupling is used, but also a set of o-rings made of ceramic or steel. Through these rings, a high degree of tightness of the water-bearing part is ensured, which increases the reliability of the unit. In addition, the device of the circulation pump in the Inline configuration assumes a linear arrangement of the outgoing and bringing branch pipes. For comparison, other versions of models with a “dry” rotor are characterized by radial or circular placement of nozzles for communication support.

In general, isolation of the rotor from the coolant gives a positive effect in terms of productivity (efficiency of more than 70%), therefore this technique is often used in the maintenance of long heating networks with high throughput. This is the best solution for industrial facilities, but in the household sector is quite troublesome and uncomfortable in terms of service.

Performance characteristics

First of all, when evaluating the characteristics of the circulation pump, you should make sure that it is, in principle, suitable for working with the target liquid medium in a specific temperature regime. As already mentioned, such equipment can withstand from 90 to 110 ° C. Next, you can move on to design parameters, the main of which, in addition to dimensions and configuration of the engine, will be the diameter of the threaded connection. For example, the Grundfos UPS-25/40 circulation pump device allows connection to pipes with an external thread diameter of 25 mm. The second figure in the marking of the Danish unit indicates the force of pressure. In numerical terms, this is 40 dm or 4 m of water, which can be maintained at maximum capacity utilization. Again, you should not consider this value as the main working parameter that will allow you to deliver water to a given height. This is nothing more than the level of rise within the heating circulation network. In comparison, boosting pressure models for water supply systems are capable of raising liquid by 12-15 m in normal operating mode. As part of servicing heating circuits, pumps with an inlet pipe diameter of 32 mm and a pressure pressure of about 60 dm can also be used.

For ease of calculation of the required power, pump manufacturers specifically indicate the speed of the coolant. This value directly depends on the power potential of the engine and the size of the nozzle. Typically 1 kW equates to 0.06 m 3 / h. An alternative calculation system suggests starting from the fact that if the diameter of the outlet in the circulation pump for heating is the same 25 mm, then the flow rate will reach 30 l / min. But this is a small amount, since most modern models even reach the domestic segment in terms of productivity of 170-180 l / min. The balance between structural throughput and engine power is provided by the function of adjusting the rotation of the shaft. Models with this feature allow you to perform step switching from 2 to 4 speeds.

Pump electrical engineering

Typically, asynchronous electric motors are used as a power unit, which are connected to a network with a voltage of 220 V. The average current strength is 0.12-0.18 A. The basis for the connections is a complex of a terminal box, a frequency switch and cable connections. The Wilo Star-RS range of circulation pumps also provides condensate drainage and two-way cable connections with a blocking protection system.

But it is far from always possible to realize on the basis of the pump itself a full range of devices for electrical protection. Therefore, external devices will play a significant role in organizing the energy supply system. At a minimum, a voltage stabilizer and a short circuit protection system should be provided - of course, the grounding requirements cannot be ignored. What is more important, in networks with periodic blackouts, it will not be out of place to think over the issue of providing backup power to the circulation pump. Devices for solving such problems are presented in a wide range - from external batteries (batteries) to stand-alone generators. The choice of specific equipment depends on the conditions and operating modes of the pump. If we are talking about a private house, where the power supply is interrupted in exceptional cases, then you can choose a battery of the appropriate volume with regular support for energy. But in the face of an acute shortage of electricity at remote sites, it is better to use a gas generator or diesel engine block with an autostart system. By the way, the operation of low-power pumps up to 30 W for a couple of days can be supported by car batteries, but this option should be used only in extreme cases.

Pump installation

By the time of installation, both the place of operation and the unit itself should be prepared. As for the first condition, they should be ready to connect pipes with shut-off valves in front of the connection points to shut off the water. The pump, in turn, must be thoroughly flushed and checked for structural integrity. The insert is carried out using a coupling and a lock nut with sealing materials. To increase the reliability of the control loop, a bypass is sometimes provided in the installation device of the circulation pump. This is a crawler on the equipment placement circuit, which is a segment of the pipeline running parallel to the critical technological zone and acting as a backup route for the delivery of coolant. On the same segment, you can install additional functional equipment like filters, air vents and just stop valves.

Maintenance

In intensive operation mode, it is recommended to check the condition of the working part and the pump connection monthly. Comprehensive maintenance work is carried out before and after the heating season along with pressure testing of the plumbing system. Among the main measures for servicing the pump are the following:

- Checking the technical and structural condition of the equipment.

- Replace wear elements if necessary. As already noted, in the circulation pump device there are parts with a limited resource set by the manufacturer. For example, seals and couplings last 1–1.5 years on average, after which they should be replaced.

- Cleaning the housing surfaces and functional parts from contamination.

- Checking the operation of the engine - it is necessary to check its ability to maintain power load, the level of noise and vibration.

- Particular attention should be paid to the tightness of the structure and the connecting nodes.

- Checking the electrical infrastructure and the quality of connections with devices connected to the pump.

Possible breakdowns and repairs

During the operation of the equipment you may encounter the following technical problems:

- The unit does not start. Possible causes may include a broken electrical connection or a capacitor malfunction. If the “wet” rotor is provided in the circulation pump device, then as a result of its contamination with coolant impurities, engine blocking may well occur. Accordingly, a general audit of the electrical system with communications, verification of the capacitor and cleaning of the rotor will be required.

- The pump is noisy and vibrates a lot. Typically, such problems are associated with high water consumption, which does not correspond to the capacity of the equipment. Also, airing of the heating circuit is not ruled out. Air from the system should be routed regularly, for which an automatic air duct is used.

- The unit turns on and off immediately. A common problem that is more common with console models. Repair of the circulation pump for heating in this case comes down to restoring the tightness of the structure at the interface between the working blocks. In the area between the stator jacket and the rotor, limescale should also be cleaned if any.

Conclusion

Coolant circulation can be organized without the support of pumping equipment in the natural mode of movement. Such schemes are used in private homes, but they do not differ in high performance, in terms of heat transfer. At the same time, for example, the Grundfos circulation pump device provides for the possibility of connecting boiler equipment, which takes the function of the unit far beyond just regulating the flow of the heating system. New possibilities for providing a hot water supply system appear, but within the framework of the technical and operational potential of the equipment used. There are also possible schemes for combining the heating circuit with the air conditioning system in which the circulation pump will be used, however, such configurations require careful calculation at the design stage.