The modern market of building materials is represented by heaters of various types and brands. One of the most popular varieties are basalt slabs and mats. Many manufacturers produce such products - both foreign and domestic. For example, the Rockwool basalt insulation produced by a group of companies of the same name has a very good reputation.

Rockwool - 80 years on the market

The first plant for the production of building materials "Rockwool" first released its products back in 1937. By the end of the 50s, the company was the owner of six factories located in different countries of Europe. Today it is a large group of companies, which owns 27 factories around the world. Their specialization is the production of materials intended for insulation, sound insulation and fire protection of structural elements of residential and industrial buildings. The company’s central office is located in Hedehusen in Denmark.

Heater "Rockwool": technical specifications. Density

The value of this parameter in most cases affects the degree of thermal conductivity of cotton wool. That is, the denser the material, the worse it retains heat. However, the features of the technological process for the manufacture of Rockwool insulation are such that this rule practically does not apply to it. So, for example, materials with a density of 35 and 200 kg / m 3 in terms of thermal conductivity differ by only 0.002 W / m.

Heater "Rockwool": technical specifications. Degree of thermal conductivity, vapor permeability and moisture absorption

The quality and effectiveness of building protection from material properties are directly dependent. The degree of thermal conductivity of Rockwall insulators can fluctuate within (0.036–0.038 W / m K). This means that a five-centimeter layer of material will retain heat as well as 96 cm of masonry. In the summer, it will be cool in a house whose enclosing structures are sheathed with this insulator, and in winter it will be warm.

Another important indicator for this kind of building materials is the degree of vapor permeability. So called the ability of plates and mats to pass through its thickness air saturated with water vapor. For Rockwool insulation, this figure can reach more than 0.25 mg / (m * h * Pa). Given that the hydrophobicity of this material is very high (and therefore, it does not absorb moisture well), the structures protected by it do not damp or rot. The water absorption coefficient of the most popular modification “Light Butts Scandic” is no more than 330. As you can see, in fact a good choice can be insulation “Rockwool”. Technical specifications for moisture allow it to be used even in fairly damp rooms.

Unfortunately, in our country there are no methods to accurately determine the durability of the insulation. However, the company "Rockwool" has developed its own technology for determining the quality of manufactured materials and their durability. In addition, observations on the behavior of heaters have been carried out by its specialists for many years, starting from the first batches leaving the assembly line. All this allows us to conclude that the Rockwool insulation can serve for more than 50 years, subject to the rules of its installation and operation.

Soundproofing properties

Insulation "Rockwool", the technical characteristics of which were discussed above, can be used, including as a sound insulator. At the same time, it is worth buying material with a high density (at least 45 kg / m 3 ). The company also manufactures slabs designed specifically for this purpose - Rockwool Acoustic Butts. The manufacturer recommends installing them in the frame on vibration pads or in "floating" floors. In the latter case, you can also use a modification of Rockwool Flor Butts. Its advantage is that the screed can be put directly on it.

Environmental Safety

Everyone knows that in the production of mineral watts , compositions containing phenol-formaldehyde resins are used. Therefore, when warming residential buildings, it is recommended to use only high-quality materials of this type. The latter can also be safely attributed to the Rockwool insulation. In its production, new generation resins are used to bind basalt fibers . The content of the binder in which they are included in the plates and mats does not exceed 3.3%. The resin is in a solid state, and therefore does not pose any danger to the environment and human health.

All Rockwool products have expert opinions on compliance with sanitary standards. In addition, all cotton wool of this brand has an EcoMaterial Green certificate. This suggests that these products can be used in absolutely any premises, including wellness and children.

Popular types of cotton wool and sizes

Heater "Rockwool", the technical characteristics of which make it possible to judge him as one of the best today, is available in:

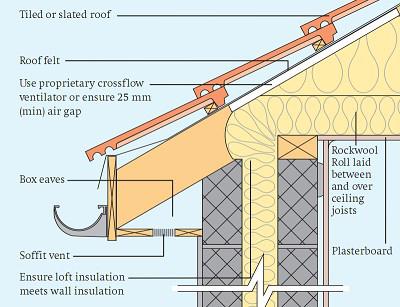

- Matah. This soft cotton wool, supplied in rolls, is usually used to insulate structures that do not experience external loads. Where can I specifically use this Rockwool insulation? Technical characteristics for roofing or insulation of walls can be considered simply ideal.

- Plates. This type of insulation can be either hard or soft or semi-soft. In the first case, it is usually used for insulation of floors and floors.

- Cylinders. This type of material is used for insulation of communication pipes.

As for the size of the insulators, they can be very different. Modification of Light Butts Scandic is a plate 1200 * 600 cm with a thickness of 5 cm or 800 * 600 with a thickness of 5 and 10 cm. Since the step between the racks of the frame of houses or rafters of roofs is usually 60 cm, this version is very convenient to use. Insulation "Rockwall Scandic", the technical characteristics of which allow it to be used on objects of various purposes, including the construction of private houses, is currently the most popular type of this brand.

Modification "Light Butts" has the same dimensions 1000 * 600. The thickness of the material can vary from 5 to 20 cm. Semi-rigid Rockwool Flexi-Batts boards are 560-1020 cm long, 900-1000 cm wide and 5-20 cm thick. There are other varieties of this material (Rollbatts-Dk, Venti- Batts-Dk, etc.). Such insulation "Rockwool", technical specifications (dimensions and density) may have different.

Heat insulators for very hot surfaces

The company "Rockwool" has a line of materials intended, including for the insulation of fireplaces, chimneys and stoves. This, for example, Rockwool "Tech Butts", Rockwool Wired Mat or Rockwool "Fire Butts". These materials can be used to isolate structures whose surfaces are heated to a temperature of no more than 750 degrees.

Rockwool reviews

Thus, we have found out in general terms what “Rockwool” insulation is (technical specifications). Customer reviews of this material are mostly positive. Internet users on forums especially emphasize such qualities as ease of installation and excellent heat-preserving properties. It is recommended to use this insulation to insulate the walls of not only residential buildings, but also baths, terraces, etc. When installing "Rockwool" does not crumble, does not fall apart and does not fly around the house.

Some owners of country houses when working with this material, however, sometimes itchy hands and body. But this, in principle, is a common drawback of all mineral watts. The manufacturer "Rockwool" advises to work with their plates only with gloves and in tight enough closed clothing. Some consumers do not like the cellophane packaging of this material. During prolonged storage of stoves in a garage or a utility unit, or during transportation, it sometimes breaks.

How to choose the right thickness

Insulation "Rockwool", the technical characteristics of which allow it to be used for insulation of any buildings, should be selected taking into account some important points. The most significant parameter, in addition to density and stiffness, is the thickness of the material. Choose it should be guided by the norms of SNiP 23-20-2003. The calculation is made according to special tables taking into account climatic conditions and the degree of thermal conductivity of the material. Usually, to insulate a residential building, it is enough to install two layers of Rockwool slabs of 5 cm each or one layer of 10 cm. The company’s official website also has a special calculator that can be used to make accurate calculations.

Rules for installing Rockwool insulation

Mount materials of this brand in the same way as mineral wool of any other manufacturer. That is, when inserting plates between the racks of the frame or rafters, you need to try not to crush them. Otherwise, they will lose some of their thermal insulation properties. When installing inside or outside, it is not necessary to lay the wall structure under the slabs with any vapor or waterproofing material. Above the heater they are installed necessarily. When installed from the inside - vapor barrier, outside - waterproofing. Between these layers and the fine finish must be arranged ventilation gap. If the plates stand between the racks tight enough, they are not additionally required to be fixed, even if two layers are used.