The inverter belongs to modern welding machines without a transformer, which has always created significant dimensions and weight. The device is a power supply with the necessary parameters at the output, ensuring the normal process of creating one-piece connections. The welding inverter "Resanta SAI-190" became popular in Russia. Feedback may not always be objective, because the level of users is significantly different. If you use the device correctly, it will cook well even with a low mains voltage.

Advantages

The welding machine has the following advantages:

- a semi-industrial model is used for short-term repairs, but can be used for large volumes of welding;

- small weight and dimensions;

- forced cooling reliably protects against overheating;

- good performance;

- different metals can be welded;

- energy efficiency and electrode consumption;

- smooth regulation.

disadvantages

The disadvantages include the following:

- short welding cable;

- Electronics does not like low temperatures, and the fan in the cold can freeze and stop;

- there is no advantage in price compared with similar devices

- short length of welding cables (2.5 m), which creates inconvenience during operation.

Budget products made in China are unstable. This also applies to the Resanta SAI-190 model. The review also depends on the functionality: the higher it is, the more expensive the device, and the price-quality ratio does not suit everyone.

Features of Resanta models

Modern manufacturing technologies make the device more reliable and more maintainable, and also allow for high-quality welding. Devices can also work with non-ferrous metals and cast iron.

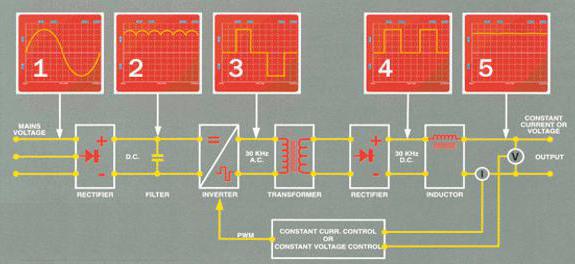

The principle of operation of new devices is based on the conversion of mains voltage to pulse. These also include Resanta SAI-190. The operation scheme allows you to rectify alternating current, and then makes it high-frequency. After that, the voltage is reduced to working with a small transformer.

The welding process is facilitated by the introduction of the new hot start and anti-stick functions. In the first case, arc ignition is accompanied by a short-term increase in the welding current and its decrease to normal, so that the electrode does not stick to the part. With a short circuit, the current decreases sharply, and after the electrode is detached, the system immediately restores the parameters of the arc burning. As a result, it easily becomes stable, and the welding process is facilitated and allows beginners to quickly get used to it. There is no need to adjust the parameters, since they always work during operation. There is no need to keep a smooth electric arc, as it is automatically maintained.

Modification of "Resanta SAI-190PN" can work with a large decrease in network voltage. In other parameters, models with the same maximum welding current do not differ much from each other.

Specifications

The device "Resanta SAI-190" has the following characteristics:

- Welding current - 10 ... 190 A.

- The maximum current of the primary winding is 25 A.

- Electrode diameters up to 5 mm.

- Input voltage - 140 ... 240 V.

- Duration of work - 70% at a current of 190 A, for example 7 minutes. continuous welding and a break of 3 minutes

- No-load voltage - 80 V, providing easy ignition of the arc.

- Arc voltage - 27 V.

The device is equipped with electrical sensors, which include an alarm indicator of overheating, and protection is triggered. The reasons may be different, and it will not hurt to make sure once again that there is no short circuit between the welding cables. If the current is about 60% of the maximum, the protection against overheating will not be triggered. When welding metal with an electrode with a diameter of 3 mm, a current of 90-110 A is selected. In this case, the margin should be 1.5-1.6 times. Then the device is selected at 160 A, and better - at 190 A. The energy consumption does not depend on the type and power of the selected model, but on the set welding current.

Which device is better to choose

The choice of device depends on the amount of further work. If they are long, you should take a powerful professional device. Its price is high, because the electrical circuit provides a long mode throughout the working day (8 hours). A small-capacity household welding machine is designed to operate for no more than half an hour, after which a break of 30-60 minutes is required to reduce the temperature.

The choice of device also depends on the voltage of the mains. If it is higher than 210 V, a device with a maximum current of 160 A is suitable for a house. For a low network voltage, a device with a current of at least 190 A is used.

The best inverters for welding are Fubag (Germany), Gysmi (France), Helvi and Selco (Italy), Power Man (Korea). In Russia, Chinese-made Resanta models and domestic Torus models are widely used.

Inverter device

The case is made in a classic style of coated sheet metal. The shape is made rectangular and the dimensions are 350 x 140 x 250 mm. The flat base allows you to install on any surface. For ventilation, there are slots on the side through which air easily enters the transformer.

On the front panel there are network indicators, overheating, current adjustment is made, and connectors for fastening welding cables are placed. The electronic circuit is equipped with forced ventilation, the grille of which can be seen from the outside. Inside installed 2 fans. Light weight and compact dimensions make it easy to carry the device with a shoulder strap attached to the top of the case.

Due to the metal construction, the device is not used in high humidity conditions.

Inverter Recommendations

- With an unstable supply voltage, the stabilizer will not interfere.

- It is not recommended to place the appliance on the floor during operation, so that the fan does not catch dust on the parts.

- Do not use a grinder near the apparatus due to dust and scale getting on the electronic circuit.

- In wet weather, the device should not be taken out into the open air, nor should it be covered from rain.

- Operation is permissible only with intact insulation of the mains cable and welding cables.

- When transferring the device from the street to a warm room for work, it is kept for 3 hours before turning it on.

Welding principle

The process consists in creating an electric arc melting the electrode and the edges, due to which a strong seam is formed. Its quality is checked after each interruption of the welding process. In this case, the slag is beaten off with a hammer, and the integrity and uniformity of the deposited layer is examined.

Preparing the device for work

The inverter "Resanta SAI-190" is simple to operate and quickly mastered.

It must be grounded through the power cord. First, the cables are connected to the terminals, and the current regulator is set to the minimum position. Then power is supplied to the apparatus, and the level of the operating current is set. If the electrode diameter is 5 mm, a welding current of 160 A corresponds to it, and 50 A will be sufficient for a cross section of 1.6 mm.

After stopping welding, the device turns off in the reverse order. The last step is to set the current regulator to the minimum level. Cables should always be disconnected unless further work is anticipated.

When in the room, measures should be taken to ventilate it and remove all flammable materials. Before work, protective equipment is prepared: a welding mask, work clothing, a hat and gloves.

Faults "Resanta SAI-190"

Compared with old transformer designs, modern inverters fail more often, due to the significant complexity of the devices and the abundance of electronics.

Despite the facilitation of the welding process, the current must be correctly regulated. For this, the speed of the process and the diameter of the electrode must be taken into account. With a diameter increase of 1 mm, the current should increase by 20-40 A.

Common causes of device failure are as follows:

- lack of an arc due to cable breakage, loss of "mass", burnout of printed circuit board elements, inverter overheating;

- the device heats up quickly due to a failure of the fan or accumulation of dust inside;

- the power does not turn on due to interruptions in the circuit, cable malfunction, switch or socket.

The length of the extension cord affects the welding process. If it is more than 40 m, the losses become significant, and welding is often impossible. In this case, a network wire of 4 mm 2 or more is taken. Also, the burning of contacts in the food has a great effect, creating a lot of resistance.

It is difficult to detect a malfunction in the electronic circuit. This requires special equipment, and the repair of Resanta SAI-190 must be carried out in specialized workshops. But visual inspection can reveal burnt parts and soldering irregularities.

Welding machine "Resanta SAI-190": reviews

Models of welders are constantly changing, and not all manufactured batches of products suit consumers. On Resanta SAI-190, the response will be positive if the device is correctly selected and correctly operated. For a beginner, there will be problems with any model until he is comfortable.

The advantages are especially noticeable when the Resanta SAI-190 apparatus is used with an unstable supply voltage. Feedback on another model in this regard is not always in her favor.

One of the criteria of good quality is uninterrupted operation during the week after the purchase of the device. According to customer reviews, after a long time it works without repair.

Many are not satisfied with the small length and high stiffness of the cable, creating great inconvenience in work. According to the experience of specialists, it can be extended up to 5 m if the cross-sectional area is not less than 25 mm 2 . Particular attention should be paid to terminating ends. Usually they are connected with soldered tips. It is necessary to carefully solder all the wires together.

For some users, when trying to cook a stainless steel, an electrode sticks. In this case, it is necessary to change the polarity, use special electrodes, and entrust the work to a qualified welder.

Conclusion

Welding inverters are indispensable helpers in the household. You need to take them with more power, which will allow you to cook with high quality at low voltage. Typically, devices with a welding current of 190 A cope with all tasks. Devices with a large maximum current are much more expensive.