The foundation platform for most capital construction projects is arranged using formwork. This design performs several functions, including restraining, insulating and protective. In professional construction, the system of fixed formwork is increasingly being used as the most functional and practical to use. But this method also involves different methods of execution.

Technology features

Traditional methods of creating formwork involve the temporary retention of concrete mass to form the supporting base of the building frame. By such methods, both a monolithic and a strip foundation are performed. For columnar and pile structures, formwork elements are practically not used. In turn, the technology of fixed formwork initially performs the same tasks of retaining concrete mortar, allowing it to find the desired shape for the target structure.

After hardening of the building mixture, the material is not removed, but remains in the foundation system. Moreover, the exclusion of the formwork operation is caused not so much by saving time and labor resources, as by the advantages of forming an integral structure. The components of the formwork after pouring and crystallization of concrete not only create a single foundation structure, but also increase the insulation and protective properties of the base under the grillage. Warming, hydro and vapor barrier, as well as increasing mechanical resistance - this is the main set of qualities that endowed with fixed formwork foundation.

Block design of fixed formwork

The most common type of non-separable concrete retention system for the foundation. Typically, in this configuration, laying of solid blocks made of the same concrete, synthetic fibers in the form of fiberglass or composite, wood-shaving materials, etc. is carried out. Installation is carried out as a brickwork using building binder mixtures.

Manufacturers of prefabricated blocks of fixed formwork based on wood concrete, gypsum and polystyrene offer a more technologically advanced way of forming the foundation. A feature of such elements is the small-format layout of the foundation structure from special components. In particular, one block can be formed of several sheets stacked according to a certain scheme in the design position. Assembly is carried out according to the principle of the designer, but, as in the case with conventional blocks, it cannot do without the use of third-party fasteners. In this quality, polymer spacers are used. They allow you to accurately withstand technological gaps between the sheets, and then reliably tighten them into a single design.

Monolithic fixed formwork

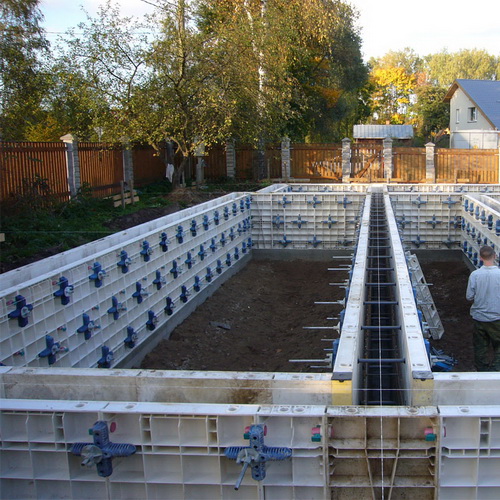

An alternative to block systems is a wide group of panel and frame materials, from which a denser foundation is obtained. It can be called monolithic conditionally, however, during operation, the structure of the poured cement is more associated with the formwork elements than with block laying. For example, in the frame layout, cast elongated beams are used, which form two load-bearing contours after installation. Concrete is poured into the created channel, after which the bars of steel reinforcement are laid.

Another way to create a foundation monolith is implemented using a fixed formwork plate that holds a continuous screed. In this design, the formwork material is a vertical fence that is installed around the perimeter of the work platform. In its framework, without additional contours, a monolithic concrete base is poured. Plates perform the function of retaining the solution, and subsequently become a full-fledged insulator and basement of the house.

Classification of fixed formwork by type of insulation

Thermal insulation is one of the key tasks of the foundation as such. The advantages of fixed formwork include the fulfillment of this function without connecting special materials like mineral wool or roofing material for waterproofing. But even in such systems, the insulation can be performed in different ways. For example, in monolithic construction using the aforementioned fencing plates, shape-forming elements are involved. As a rule, these are thermal blocks with enhanced properties of thermal energy retention.

Another option is designs with an additional insulating layer. If thermal blocks benefit from insulation as such, an independent insulation layer is advantageous for its multifunctionality. It is expressed not only in additional functions (hydrobarrier, steam protection, noise reduction), but also in wider styling possibilities. That is, it is possible to isolate not the entire area, but specific sections - including places in which the foundation converges with a grillage without formwork elements.

Styrofoam construction

In terms of technical and physical qualities, this is one of the best solutions in its class. Expanded polystyrene has a good warming function, creates a barrier to moisture and noise. The disadvantages of this material include low mechanical strength, however, all types of fixed formwork require close coupling with concrete and reinforcing rods, so even structures on plastic components can act as self-supporting. The most important advantage of expanded polystyrene is the variety of shapes and sizes. Block and panel formwork kits allow the formation of complex foundation structures without special refinement.

Timber concrete fixed formwork

There are independent wood and concrete components, however, each of these materials has pronounced disadvantages. On the contrary, their combination into one structure made it possible to obtain a universal tool for creating reliable and functional formwork. Wood-concrete types of fixed formwork received the general name arbolit. Elements of this design are installed in a row order, which as a result forms walls. The inner side of such a panel has corrugations to ensure good adhesion with concrete, and in some modifications special ditches are also provided for the installation of communication routes. The only significant drawback of arbolite (due to the presence of wood in the structure) is its high sensitivity to humidity, therefore, waterproofing of the formwork may be required as a structural addition.

Glass-magnesite fixed formwork

The material is mainly used in frame structures made using metal. The outer side of the formwork is sheathed with thin magnesium glass panels that look like plasterboard partitions. Concrete is poured into the formed channels using general technology. The use of glass-magnesite walls in monolithic construction with a tiled foundation is also allowed. In this embodiment, the partitions are not installed along the internal contours, but outside, performing the functions of the same vertical fences. As for the glass magnesite itself, it is popular as a practical structural basis for the foundation, but its insulating properties are very weak.

Fixed Formwork Technology

The workflow involves the implementation of three technological operations - assembly, pouring and strengthening. They begin assembly activities after preparing the work site. Further, various types of fixed formwork are arranged in accordance with their technical and design features. For example, block elements are joined through grooved connectors, and massive plates are pulled together by metal brackets and external cladding. When the niche for the foundation itself is ready, proceed to pouring the solution. As a rule, the height of the bearing base is 20-30 cm, but depending on the number of storeys of the house, an additional level of screed with a thickness of 12-20 cm can be arranged. Another technological superstructure of formwork elements is mounted under it. At the final stage, they are strengthened with external struts, anchor joints and metal rods.

The cost of materials for fixed formwork

The most affordable unit for structures of this type costs 150-200 rubles. As a rule, these are modules made of concrete or wood-based materials. The average price of fixed polystyrene formwork is 700-1000 rubles. Composite materials and elements based on fiberglass are evaluated at approximately the same rate.

When buying, it is important to consider the technical and physical characteristics of the material. For example, the same price of non-removable polystyrene formwork can be increased up to 2000 rubles, if we are talking about large-format panels with reinforcement inside. Also, additional thermal insulation layers with structural modifications can add 300-500 rubles. to the base cost of the item.

Conclusion

The combination of a wide range of positive operational properties, moderate cost and affordable installation technology, of course, makes the technology of non-separable formwork for the foundation attractive in the eyes of the ordinary consumer. However, are these impressions preserved during the operation of the house? Most owners do not notice the disadvantages of the technology, but they are. The specific disadvantages will depend on what kind of fixed formwork was used. In the case of expanded polystyrene, this may be a lack of foundation ventilation and the release of harmful chemicals. We are talking about vapors that are insignificant for health, but you still have to forget about environmental cleanliness. As for concrete and wood chipboards, their weaknesses are mainly due to the need to maintain structural stability due to the negative impact of soil movements at the construction site.