The need for spot processing of lumber does not cease to be relevant even in the age of new technologies, composite plastics and carbon raw materials. Natural wood due to environmental friendliness, flexibility in processing and unique texture is still of interest to both the construction and manufacturing sectors. Nevertheless, this does not cancel the process of the appearance of new technical means of processing the material, including milling cutters. The principle of mechanical correction of lumber itself has been preserved, but in recent years the technological approach to this operation has changed significantly. Therefore, for those who want to get a high-quality groove or hole in the workpiece, the following question is quite logical: "How to choose a manual milling cutter for wood?" Manufacturers produce units in different versions, so an inexperienced user will have difficulty choosing.

Submersible or motionless?

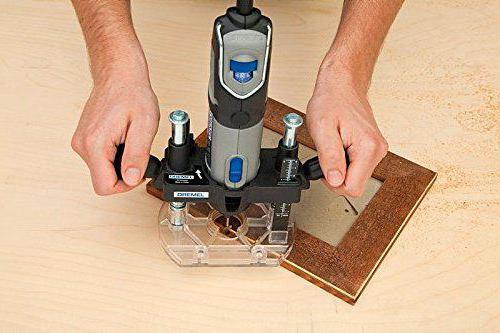

The choice should begin with the determination of the most suitable principle of work. The basic separation on this basis lies in the method of processing the target material. There are submersible and fixed modifications. What is the difference? The design of the milling cutter can be divided into two parts - a bed and functional equipment, represented by carvers and the engine. In the case of a movable structure, the bed is placed on the workpiece, and the milling cutter with the motor moves along it, realizing working steps. The stationary tool, in turn, does not imply a separate movement of the cutting part, although in general the unit can be shifted as the operation is performed. That is, the mutual coupling with the bed determines the structural and functional features that the manual wood milling machine has. Which to choose? The first option is suitable for creating profiles, grooves and holes, and the second, thanks to the adjustment of the milling depth, will optimally cope with the processing of edges.

Varieties of Professional Models

Professional, or specialized, models of milling cutters can be considered as representatives of a family of motionless models. Usually lamellar, rotational and additive units are distinguished. As for the lamella technique, it works due to the disk cutter, which the user can influence by pressing on the handle. The result is a specialized cutting tool that removes thin lamellas from the wood surface, that is, oval plate shavings. Lamella types of hand milling cutters on wood are structurally similar to filler tools. But if they are guided by a soft selection of grooves, the filler models are equipped with spiral cutters, due to which it is possible to obtain holes with exact configurations of the location. Rotary units are distinguished by an elongated body, provided with rubberized inserts. This is necessary for a more tenacious hold of the tool during work operations. The operator can form quality holes with such a milling cutter not only in wood, but also in plastic, ceramic tile and drywall.

Power selection

From the point of view of working opportunities, this is far from the most important parameter of choice. The fact is that even the minimum power potential today is enough to perform most operations. Power will more likely be seen as a class marker that determines the functional and structural capabilities of the machine, as well as weight. So, the primary class has a capacity of about 450-600 watts. This is a lightweight tool, the mass of which rarely exceeds 3 kg. And here it must be borne in mind that such models are more likely to be suitable for simple operations - for example, in removing the edges of small workpieces. If there is a question about how to choose a manual milling cutter for a universal tree, then you should rely on the middle class. These are models for 800-1250 W, the mass of which can be 5 kg. Using this unit, the operator can easily process the edges, make the necessary holes, etc. The power potential of a heavy milling machine with a power of the order of 2000 W does not directly affect the ability of efficient processing. With proper dexterity, the same quality of grooves and profiles can be obtained using a 1500 W device. But in continuous operation without interruptions, the power reserve will come in handy, since this will protect the tool from overload.

Speed selection

The number of revolutions to a greater extent affects the nature of the mechanical effect. In this case, the nominal value of the cutter rotation speed and the possibility of its adjustment will also matter. The wider the adjustment range, the more operations with high precision can be performed by the tool. The possibility of changing the number of revolutions takes place in cases where the manufacturer indicates not a specific speed at idle, but a range. How to choose the right wood milling machine by the number of revolutions? It is recommended to take into account the upper value, which averages 10,000 rpm. But in this choice, it is important to initially have an idea of the characteristics of the workpieces. The speed indicated above is suitable, for example, for working with equipment with a diameter of 10 mm. If it is planned to work with wood cutters for 40 mm, then the number of revolutions should already be about 20,000 rpm.

What should be the optimal working stroke?

If the rotation speed is to some extent a power parameter, then the stroke is determined by the structural characteristics. In other words, the sizes of the treated zone depend on it. So, entry-level models are able to perform milling at a depth of 30-40 mm, and for powerful units this value can reach 80 mm. On the question of how to choose a manual wood milling machine from the point of view of the optimal immersion depth, consideration should be given to processing restrictions. For example, the formal value of a depth of 30 mm does not mean at all that the mill will be able to achieve exactly this indicator in practice. Usually the actual value is 3-4 mm less than the declared value, which is explained by many technical factors. That is, to the required value it is necessary to add another 5-6 mm for stock.

Functional support

To increase ergonomics, safety and efficiency, manufacturers provide milling machines with additional functions. Among them, one can note the soft-start button, anti-vibration protection, overload protection systems, etc. How to choose a manual milling cutter for wood, taking into account the functional content? On the one hand, the more useful add-ons, the better. But here it is important to maintain a certain balance, since the presence of options makes the design heavier, makes it more difficult, and this is not to mention the increase in the price tag. Experts recommend sacrificing fashionable marketing inclusions that expand the scope of the tool. They are ineffective and rarely required in practice. But it is undesirable to ignore the means of increasing reliability and security.

What to consider when choosing a snap?

The main task in this part is to determine the types of mills that will be used in equipping the unit. The most common groove elements that are used in the formation of profile niches for connecting parts. They have a different diameter, as well as a structural device, which should be taken into account in the choice. Spiral types of wood cutters for wood for hand milling machines are also in demand. They are made of reinforced alloys and resemble classic drills. When choosing such milling cutters, it is necessary to immediately calculate the ability to work with metal workpieces, since such equipment, depending on the quality, can quite cope with the processing of solid materials.

Which manufacturers to prefer?

If you need a powerful milling technique, it makes sense to turn to Bosch products. German designers offer modern technological models, equipped with both wide adjustment possibilities and electronic control. Among the competitors of this manufacturer, Metabo, Makita, Einhell and others can be distinguished. But this is a group of first-class manufacturers, whose proposals are of high cost. And how to choose a manual milling cutter for wood, reviews of which equally positively reflect both the working qualities of the tool and the pricing policy of the manufacturer? This search range covers the little-known but responsible companies Talon, Sparky and the Latvian company Rebir. Users of these products indicate not only decent performance, but also emphasize the presence of a modern option that is not inferior to the level of Bosch.

Price issue

Models from premium companies like Einhell and Metabo are on average available for 10-15 thousand rubles. For comparison, Sparky or Rebir products can cost several times cheaper, but this does not mean that such equipment loses in quality. The difference in prices is often caused by the same set of options, some of which are just included to increase the price tag. A multifunctional model worth 20 thousand in practice of performing standard tasks to create a groove may well correspond to the result of the work, which will demonstrate a budget milling cutter manual for wood. Which option to prefer? Of course, the unit’s belonging to the segment of models for 3-5 thousand does not always guarantee high quality and moreover does not imply the presence of the same security systems. But in the families of the above manufacturers, decent models are also found at this price level. If you need a professional router, then it is advisable to immediately turn to the assortment of Makita or Bosch.

Conclusion

With the technological development of construction and production tools, the scope of its application is expanding. Therefore, a key criterion may be a list of tasks that a particular model can solve. But there is another position among experienced craftsmen, which suggests that the best manual wood milling machine is one that efficiently copes with 2-3 primary tasks. In this context, multifunctionality does not matter at all. As for the high-quality fulfillment of their direct tasks, this applies not only to the processing of the workpiece as such. A modern milling cutter should also be distinguished by fault tolerance, a high resource of the element base and protection from external influences.