The use of natural stone in the interior has always been rated highly in terms of attractive appearance, durability, reliability and variety of choices. However, the use of this magnificent material provides for some restrictions that do not allow the use of products everywhere. This statement is especially relevant for the private sector, since only wealthy people can afford to clad a house from the inside, while the average developer can not afford it. This is due to the fact that high-quality natural stone has a fairly high cost. Not least because of the fact that its production is carried out in certain regions. Among other things, the products have more weight, therefore, a more reliable foundation or strengthening of the old will be required. As you know, the implementation of additional measures provides for material investments.

Budget finish

As an alternative solution, you can use a material that has found its wide application in the general consumer. You can make such a finish yourself, after waiting for the curing of the corresponding mixture. A variety of substances can be used as components, but gypsum is one of the most popular. If you use it in the interior, it will be able to adjust the microclimate, give the walls the ability to breathe. Among other things, you can do this work yourself, without the help of specialists. Finished products have high environmental properties, it can be used in premises of any purpose, there are no restrictions.

In order to save even more, you can make these products yourself, without the need for any special skills. As a result, the surface will be lined with material that can have all kinds of textures and shades.

Formwork preparation

In order to make decorative stones from gypsum, you will need a form, which you can purchase at a building materials store. The cost of such products can start from 2700 rubles. a piece. You can make the mold yourself, their number will depend on the time that is supposed to be spent on production. It’s easy to understand that one form will slow down the process, and the samples will be the same. Therefore, the amount will be determined by the features of the finish and material capabilities. The more forms can be acquired or manufactured, the more diverse the products will be in texture and size.

If you decide to make decorative stones from gypsum, then initially you need to find a sample on which copies will be made. It can be any natural stone, including the one that is offered for sale. The dimensions of the form should be slightly larger compared to the dimensions of the template.

Methodology

The manufacture of artificial stone is carried out by pouring the mixture into a template, which is a silicone matrix. For this, silicone formwork is being prepared, and the choice of material for this is quite large. This can be puff, moisture-proof plywood, pieces of PVC panels, etc. It is necessary to consider before work, how many samples will need to be made, and whether the form will withstand the weight of the filled mixture.

Preparing for pouring

If you decide to make decorative stones from gypsum, then initially a natural product needs to be laid in the formwork in the center, placing the separation layer. Such a surface treatment is required to prevent bonding of the material with silicone. Processing is cheaper and more convenient to produce a solidol, which should be coated with the inner surface of the formwork, including the sample. Experts advise using Tsiatim lubricant, but it is quite expensive.

The frame should be installed on a thick plastic film, while it is important to ensure evenness of the surface. The edges of the formwork should be pressed tight enough to prevent silicone from spreading.

Matrix Work

On sale you can find a wide range of sealants, but their cost is quite high. Given that this material will need a lot, it is best to follow the recommendations of home masters who advise using silicone. It is just used for such purposes. During the pouring process, it is necessary to check that the mass is distributed evenly over the entire area. In order to correct the position of the composition, you can use a brush, soaking it in a solution of detergent. However, its composition should not be alkali. For this reason, laundry soap is not recommended if citric acid is added to the mixture. The thickness of the template should be such that its operation lasts as long as possible.

Once the mass has dried, it can be removed from the formwork and inspected for quality. The resulting shells are sealed with silicone, and the formed protrusions are smoothed, that is, cut off. It is important to consider that silicone cures slowly throughout its depth. As practice shows, with a layer of one centimeter it will be necessary to wait about a week or more. This is important to consider and allow the template to rest on the formwork. The period can be shortened by placing the frame in a warm room. It is not worthwhile to force silicone to solidify by heating.

What else you need to know about making a template

The production of decorative stone from gypsum, as mentioned above, is impossible without the use of molds. For its implementation, you can use the usual box, the area of which will be able to fit all the stones that act as a template. Once the elements can be compactly placed in a box, you can begin to fill the silicone. Sealing should be done with a paint brush, which is often wetted in ordinary Fairy. Such forms can dry out even up to 3 weeks, after which the formwork can be freely disassembled, samples can be taken, which will make it possible to obtain ready-made silicone forms.

For reference

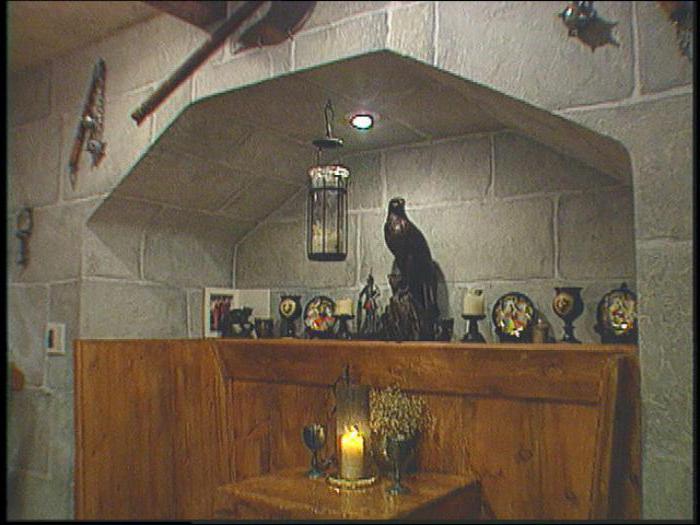

If you will be making a decorative stone from gypsum, a photo of which you can see in the article, then the template can be made independently, and not purchased in a store. The cost of a home-made form can vary from 220 to 280 rubles. If desired, up to 40 tile samples can be cast in it.

Mixture preparation

Instead of stone, a silicone mold should be installed in the frame. Plaster mix is not a shortage and is sold in any specialized store. The main question that the masters are asked before making a decorative stone from gypsum for interior decoration: what kind of tiles should be - painted or have a natural color? It will be cheaper to color the products, but the durability will not be too high. If you want to get a better finish, it is best to add color, while the dye is poured or falls asleep to the ingredients. When you will be making decorative stone from gypsum for interior decoration with the addition of color, you should be prepared for the fact that the elements are expensive. In order to save money, pouring is best carried out in two stages, for each of which its own composition is prepared. You can add dye to the top layer. First, a colored mixture is poured, which requires the compaction. Most often, the mixture is pierced with wire over the entire area, which allows you to remove excess air. A layer of the second composition is poured on top, during manufacture it is not painted. It should also be condensed.

Strength and grip enhancement

When decorative gypsum stones are made at home, they need to be given increased strength. For this, a reinforcing material should be laid on the first layer of the mass, which is a mesh for plastering. Among other things, you can prepare the mixture not from pure gypsum, but with some cement. In this case, the brand of the last ingredient does not matter. It is necessary to use the ratio, which provides for the use of part of cement and two parts of gypsum.

The manufacture of decorative stone from gypsum can be accompanied by an increase in the quality of adhesion of products to the surface being trimmed. To do this, longitudinal strips must be applied to the upper part of the hardening mass, after which the mixture will set quite quickly. You can apply the finished tile in about an hour.

Stone recommendations

The resulting products are not recommended for external decoration. If you decide to lay this material on the walls of a room with high humidity, it will be necessary to carry out a number of measures that will protect the blocks from the negative effects of water. Additionally, the walls are impregnated with a primer, and the surface is varnished. And as an alternative option is the introduction of plasticizers, namely polymers.

If you want to make a decorative stone from gypsum with your own hands, then the substance that is intended for the preparation of concrete solutions may be the coloring component. The weight ratio between dye and gypsum should be 1:20. After the finished tile is removed from the mold, the template should be washed with soapy water. Experts advise adding citric acid to the ingredients if there is a need to increase the setting time. Of the total mass, the acid should be 0.4%. When working at home, 4 templates for each tile size will suffice.

Choice of adhesive and finish recommendations

As soon as the products are ready, you will be faced with a reasonable question: what to glue decorative stone from gypsum? An additional advantage is the ability to use almost any adhesive solution available for installation work. This can be acrylic glue, liquid nails, thickened paint, mounting polymer sealant, putty, PVA, cement dry mixes, tile glue, as well as CMC.

For laying, you can use one of two technologies, the first involves the presence of seams, while the second provides for their absence. Before making decorative stones from gypsum, it is necessary to choose a more suitable principle for laying the cladding in order to correctly calculate the amount of material. If you decide to prefer a seamless method, then the material consumption will be 15% higher.

Finishing with decorative stone made of gypsum should be carried out on a perfectly flat surface, in this case the consumption of the adhesive composition will be less. The base must be firm and dry, and before starting work it is important to check if there are any flaking elements that need to be disposed of.