Space heating provides many options. For a new house of 2-3 floors with concrete floors, there are no problems at all. If necessary, it is necessary to seriously work to heat the previously abandoned attic, which has turned under the influence of fashion into a residential attic. Getting a dry warm floor in a wooden house is somewhat more difficult due to the lightweight design, which is not able to withstand heavy weight. Owners of prefabricated buildings face the same problem.

However, this is not a reason to deny yourself the pleasure of installing a comfortable and economical heating system instead of an expensive electric one. Many are also stopped by the need for radiator heating in order to get underfloor heating. In fact, a water heated floor is installed together with a radiator system to increase the heating rate of the room.

Manufacturer's method of laying on a wooden surface

To obtain the desired result, it is necessary to correctly lay the water wooden warm floor. Installation instructions recommend the use of special metal plates in this case. They gather among themselves thanks to convenient grooves. Pipes are mounted directly in the plate, where the necessary grooves are provided. The design, despite its lightness, is highly durable. The wooden water floor heating system allows you to lay the floor immediately after installing the pipes. For residents of remote regions, acquiring such a system is a great success. Most suppliers do not like to expand their assortment with goods for which there is almost no demand. Do not forget about the high cost of the material.

The desire to lay underfloor heating underfloor heating on a wooden floor with the pre-ordering of the necessary aluminum layout from the supplier contributes to many times the planned costs.

Alternative styling method

Masters have long learned how to create quality products, assemble structures, replacing missing parts with materials at hand. Water floor heating can be laid on a wooden floor using the principle of air thermal insulation. Interfloor ceilings filled with heat and sound insulating filler stably retain heat, not allowing it to penetrate to the lower floor. A leveling layer of plywood or OSB is laid on the beams.

The next element performs the functions of heat distribution and its direction in the right direction. It becomes aluminum foil. Preference is given to strong dense brands used in saunas or baths. It is also necessary to take care of the waterproofing and vapor barrier of the structure. To increase the efficiency and safety of the system, laying a water heated floor on a wooden floor, use a metal corrugated pipe. It is resistant to small movements and is able to compensate for inaccuracies made during installation.

Thin screed

Some wooden floors allow screeding. At the same time, their design load limits its layer thickness to 5 cm, and more often to 3 cm. Warm water floors are laid on a wooden floor in the presence of a qualitatively mounted heat removal from the pipe. Following the standard principle of installing a water floor, the missing thickness is compensated by foil. The foil is laid in a dense layer directly under the screed. An additional material that helps to evenly distribute heat in the structure is a reinforcing mesh, which simultaneously increases the strength of the screed. Screed can be filled only after laying pipes and filling them with water. All further work can be done only a month after that.

Disadvantages and advantages of underfloor heating

Warm floors "work" throughout the entire area of the house, which allows not only to get a pleasant to the touch surface, but also to contribute to the overall heating of the home. Studying how to make a warm floor in a wooden house with his own hands, the owner will first assess the complexity of installation and compare the cost-effectiveness of water and electrical systems. The efficiency of full-fledged heating boilers significantly exceeds the performance of an electric floor heating, which tilts the scales not in favor of the latter.

With a huge number of positive reviews and recommendations, a warm water floor has drawbacks. They are associated with the features of operation. It is necessary to cover the floor with carpet, linoleum, as the floor immediately ceases to warm up properly. When laying on a screed with tile pipes, it should be provided that, due to the temperature difference, the glue may not withstand and crack. Another drawback is the high cost of floors, which is about 1500 rubles only for materials when calculating per 1 sq.m. The price, together with the work, can reach 3000 rubles per 1 sq.m.

Purchase of necessary materials

Do-it-yourself warm water floor in a wooden house can be mounted without problems if the necessary materials are available that correspond to the chosen installation method. The main set of components is as follows:

- Specially designed for similar pipe operating conditions. For the calculation, one should proceed from the standard flow rate - 6 meters per square meter.

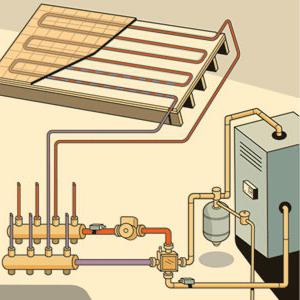

- Collector and shield for him. The choice of location for the collector should be taken care of in advance, the main requirement is its availability.

- Plastic clamps and other possible pipe mounts.

- Working boiler. It should be provided that the boiler must be able to connect water floor pipes.

- Reinforcement mesh and materials necessary for screed (if possible).

- Thick foil.

- Waterproofing and vapor barrier materials.

Preliminary work

Water underfloor heating on a wooden floor is allowed to be installed after the completion of the replacement of windows and doors in the room, the completion of plastering, the withdrawal of plots for the subsequent connection of sewers, water, electricity. Then work is done to level the floor using OSB boards or plywood. The difference in height per 1 square. m for the heating system may not exceed 5 mm.

Thermal insulation - the beginning of all work

All thermal energy should be directed strictly up. Proper heat insulation allows avoiding heat loss. Do-it-yourself warm water floor on a wooden floor begins to be mounted taking into account the peculiarities of the ceiling. For interfloor overlapping, 20 mm of insulation material with a density of 25 kg per m 3 is sufficient. For cold floors, the thickness of the insulation increases to 50 mm at the same density. In this group of construction products, polystyrene in plates is especially popular. Plates are laid on the entire surface of the floor, fastened together with special locks. When mounting a water floor on a wooden surface, it is recommended to use foamed foamed foil.

Mounting on a concrete screed

Waterproofing and heat-insulating layers and reinforcing mesh are laid on a pre-cleaned surface. The latter should be raised 1.5 cm above the base. The first pipe is connected to the feed manifold, then the laying process takes place in accordance with the intended scheme. When choosing a snake scheme, the workflow is greatly simplified. It’s not difficult to mount a warm water floor on a wooden floor with your own hands, but in the future you will have to deal with the difference in surface temperatures in different parts of the room.

A more labor-intensive laying pattern - “spiral” - repeatedly justifies the efforts made during further operation. Between the turns, a distance of about 20 cm (+10 cm) should be maintained, depending on the characteristics of the room. Each linear meter of the pipe is attached to the valve taking into account the expansion during heating. The length of the circuit should not exceed 60 meters. Before the screed is completely poured, the system should be checked carefully. The filling height is about 5 cm above the pipe. The composition of the mixture must include a plasticizer, allowing the plate to maintain strength in a temperature differential. It needs 28 days to dry completely.

Installation of underfloor heating without screed

Warm water floors on a wooden floor are laid after the preliminary installation of special mats. They serve as an excellent basis for the working circuit and metal plates, ensuring uniform heating of the surface.

The following algorithm is used:

- a damper tape is glued around the perimeter of the room;

- waterproofing is laid;

- foam polystyrene mats (penofol) are placed; metal plates of the structure are mounted in them;

- the contour of the warm floor is displayed;

- After checking the system, a finish coating is laid.

Collector connection

Regardless of the chosen method of laying pipes for the underfloor heating, they must be connected to the collector. The first pipe is connected to a collector that supplies hot water. The opposite end is to the cooled water return manifold. The pipes are fastened with the help of special nuts. Connecting pipes to the collector is the final stage of installation, after which the design should not be subject to shear, impact, or other mechanical stress from the outside. At this stage, the entire system is checked. The boiler is turned on at full power, the water entering the pipes will move under pressure. The pressure during the inspection exceeds the working pressure by 1.5 times. In such conditions, the system must be worked out for at least 2 hours to ensure that there are no installation defects (pinched pipes, unreliable connections).

Final stage

Do-it-yourself warm water floor in a wooden house is first of all mounted taking into account aesthetic qualities. The main thing is a beautiful design of the entire structure with the help of a finishing floor. If a screed was used, then directly on it you can lay ceramic tiles. It should be noted that saving on glue can destroy the impression of the interior in the near future. Tile laying work will have to start all over again.

For natural wooden surfaces in the form of a board, parquet or laminate, no additional interlayers are required. They are laid immediately on top of the structure in which the screed was not used. For other materials, it is recommended to pre-lay the OSB sheet.