Electromagnetic screens are widely used in industry. They serve to eliminate the harmful effects of some elements of the electrical device on others, to protect personnel and equipment from the effects of external fields that arise during the operation of other devices. "Extinction" of the external magnetic field is necessary when creating laboratories designed for the commissioning and testing of highly sensitive equipment. It is also required in medicine and in those areas of science where fields with ultra-small induction are measured; to protect information during its transmission via cables.

Methods

Shielding a magnetic field is a set of methods for reducing the intensity of a constant or alternating field in a specific area of space. The magnetic field, unlike the electric field, cannot be completely weakened.

In industry, the greatest environmental impact is exerted by the scattering fields arising from the operation of transformers, permanent magnets, high-current installations and circuits. They can completely disrupt the normal operation of neighboring devices.

Most often, 2 protection methods are used:

- The use of screens made of superconducting or ferromagnetic materials. This is effective in the presence of a constant or low frequency magnetic field.

- Compensation method (quenching by eddy currents). Eddy currents are volume electric currents that occur in a conductor when the magnetic flux changes. This method shows the best results for high-frequency fields.

Principles

The principles of magnetic field shielding are based on the laws of magnetic field propagation in space. Accordingly, for each of the above methods, they are as follows:

- If you put an inductor in a casing made of a ferromagnet, then the lines of induction of the external magnetic field will pass along the walls of the protective shield, since it has a lower magnetic resistance compared to the space inside it. Those lines of force that are induced by the coil itself, also almost everything is closed on the walls of the casing. For the best protection in this case, it is necessary to choose ferromagnetic materials that have high magnetic permeability. In practice, iron alloys are most often used. In order to increase the reliability of the screen, it is made of thick-walled or prefabricated from several casings. The disadvantages of this design is its heaviness, bulkiness and deterioration of shielding in the presence of seams and cuts in the walls of the casing.

- In the second method, the weakening of the external magnetic field occurs as a result of the imposition of another field on it, induced by ring eddy currents. Its direction is back to the lines of induction of the first field. With increasing frequency, attenuation will be more pronounced. For shielding in this case, plates in the form of a ring of conductors with low resistivity are used. As screens, casings, cylinder-shaped boxes made of copper or aluminum are most often used.

Main characteristics

To describe the shielding process, 3 main characteristics are used:

- Equivalent penetration depth of the magnetic field. So, let's continue. This indicator is used for the screening effect of eddy currents. The lower its value, the higher the current flowing in the surface layers of the protective casing. Accordingly, the greater the magnetic field induced by it, which displaces the external. Equivalent depth is determined by the formula below. In this formula, ρ and μ r are the resistivity and relative magnetic permeability of the screen material, respectively (the units of the first magnitude are Ohm ∙ m); f is the frequency of the field, measured in MHz.

- Screening efficiency e is the ratio of the magnetic field strength in the screened space in the absence and presence of a screen. This value is the higher, the greater the thickness of the screen and the magnetic permeability of its material. Permeability is an indicator that describes how many times the induction in a substance differs from that in a vacuum.

- Reducing the magnetic field and the density of eddy currents at a depth x from the surface of the protective casing. The indicator is calculated by the formula below. Here, A 0 is the value on the screen surface, x 0 is the depth at which the intensity or density of currents decreases e times.

Screen designs

Protective covers for shielding the magnetic field can be made in various designs:

- leafy and massive;

- in the form of hollow tubes and casings with a cylindrical or rectangular section;

- single and multilayer, with an air gap.

Since the calculation of the number of layers is rather complicated, this value is most often chosen from reference books, from shielding efficiency curves that were obtained experimentally. Cuts and seams in boxes are allowed to be carried out only along eddy current lines. Otherwise, the shielding effect is reduced.

In practice, it is difficult to obtain a high shielding coefficient, since it is always necessary to make holes for cable entry, ventilation and maintenance of installations. Seamless coils for coils are made by sheet extrusion, and the bottom of the cylindrical screen serves as a removable cover.

In addition, upon contact of structural elements, cracks form due to surface irregularities. In order to eliminate them, apply mechanical clamps or gaskets of conductive materials. They are available in different sizes and with different properties.

Eddy currents are currents that are much less circulating, but they are able to prevent the penetration of a magnetic field through the screen. In the presence of a large number of holes in the casing, the reduction of the screening coefficient occurs according to the logarithmic dependence. Its lowest value is observed with large technological holes. Therefore, it is recommended to design several small holes than one large one. If it is necessary to use standardized openings (for cable entry and other needs), then transcendent waveguides are used.

In a magnetostatic field created by direct electric currents, the screen works by shunting the field lines of force. The protective element is installed as close as possible to the source. Grounding is not required. Shielding efficiency depends on the magnetic permeability and the thickness of the screen material. As the latter, steel, permalloy and magnetic alloys with high magnetic permeability are used.

Shielding of cable routes is mainly performed by two methods - using cables with shielded or protected twisted pair and laying conduits in aluminum ducts (or inserts).

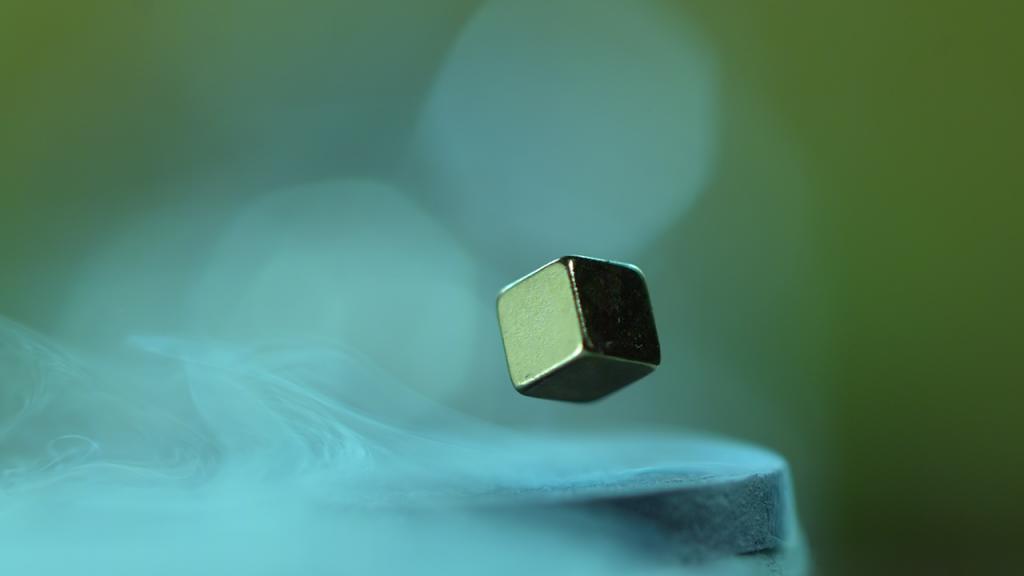

Superconducting screens

The operation of superconducting magnetic screens is based on the Meissner effect. This phenomenon consists in the fact that a body located in a magnetic field passes into a superconducting state. In this case, the magnetic permeability of the casing becomes equal to zero, that is, it does not pass a magnetic field. It is fully compensated in the volume of this body.

The advantage of such elements is that they are much more effective, protection from an external magnetic field does not depend on the frequency, and the compensation effect can last arbitrarily long. However, in practice, the Meissner effect is not complete, since in real screens made of superconducting materials, structural inhomogeneities are always present that lead to magnetic flux capture. This effect is a serious problem for creating enclosures with the aim of shielding the magnetic field. The attenuation coefficient of the magnetic field is greater, the higher the chemical purity of the material. In experiments, the best performance was observed in lead.

Other disadvantages of superconducting materials for shielding a magnetic field are:

- high price;

- the presence of a residual magnetic field;

- the appearance of a state of superconductivity only at low temperatures;

- inability to perform their functions in magnetic fields with high tension.

Materials

Most often, carbon steel screens are used to protect against magnetic fields, since they are highly adaptable to welding, soldering, and inexpensive and are characterized by good corrosion resistance. In addition to them, materials such as:

- technical aluminum foil;

- soft magnetic alloy of iron, aluminum and silicon (alsifer);

- copper;

- conductive coated glass;

- zinc;

- transformer steel;

- conductive enamels and varnishes;

- brass;

- metallized fabrics.

Structurally, they can be made in the form of sheets, nets and foil. Sheet materials provide better protection, and mesh materials are more convenient to assemble - they can be joined together by spot welding with a pitch of 10-15 mm. To ensure corrosion resistance, the nets are varnished.

Material Guidelines

When choosing a material for protective screens are guided by the following recommendations:

- In weak fields, alloys with high magnetic permeability are used. The most technologically advanced is permalloy, which lends itself well to pressure and cutting. The magnetic field strength necessary for its complete demagnetization, as well as the electrical resistivity, depend mainly on the percentage of nickel. Low nickel (up to 50%) and high nickel (up to 80%) permalloys are distinguished by the amount of this element.

- To reduce energy losses, shrouds are placed in an alternating magnetic field either from a good conductor or from an insulator.

- For a field frequency of more than 10 MHz, coatings made of silver or copper film from a thickness of 0.1 mm or more (screens from foil-coated getinax and other insulating materials), as well as copper, aluminum, and brass, give a good effect. To protect copper from oxidation, it is coated with silver.

- The thickness of the material depends on the frequency f. The lower the f, the greater the thickness must be to achieve the same shielding effect. At high frequencies, 0.5-1.5 mm thick is sufficient for the manufacture of casings from any material.

- For fields with high f, ferromagnets are not used, since they have high resistance and lead to large energy losses. In order to shield permanent magnetic fields, it is also impossible to use materials with high conductivity, except steel.

- For protection over a wide range of f, multilayer materials (sheets of steel with a metal layer with high conductivity) are the optimal solution.

General selection rules are as follows:

- High frequencies - materials with high conductivity.

- Low frequencies - materials with high magnetic permeability. Shielding in this case is one of the most difficult tasks, as this complicates and complicates the design of the protective screen.

Foil tapes

Foil shielding tapes are used for the following purposes:

- Shielding broadband electromagnetic interference. Most often they are used for doors and walls of electrical cabinets with devices, as well as for forming a screen around individual elements (solenoids, relays) and cables.

- The removal of static charge, which accumulates on devices containing semiconductors and cathode ray tubes, as well as in devices used to input and output information from a computer.

- As a component of ground circuits.

- To reduce the electrostatic interaction between transformer windings.

Structurally, they are based on a conductive adhesive material (acrylic resin) and foil (with a corrugated or smooth surface) made of the following types of metal:

- aluminum;

- copper;

- tinned copper (for soldering and better corrosion protection).

Polymer materials

In those devices where, along with shielding of the magnetic field, protection against mechanical damage and shock absorption are required, polymeric materials are used. They are made in the form of gaskets made of polyurethane foam coated with a polyester film, based on acrylic adhesive.

In the manufacture of liquid crystal monitors, acrylic seals made of conductive fabric are used. In the layer of acrylic adhesive is a three-dimensional electrically conductive matrix made of conductive particles. Due to its elasticity, such a material also effectively absorbs mechanical stress.

Compensation method

The principle of the compensation shielding method is to artificially create a magnetic field that is directed opposite to the external field. This is usually achieved using the Helmholtz coil system. It is 2 identical thin coils located coaxially at a distance of their radius. Electric current is passed through them. The magnetic field induced by the coils is highly uniform.

Shielding can also be done using plasma. This phenomenon is taken into account in the distribution of the magnetic field in space.

Cable shielding

Magnetic field protection is required when laying cables. Electric currents induced in them can be caused by the inclusion of household appliances in the room (air conditioners, fluorescent lamps, telephones), as well as elevators in mines. These factors have a particularly large influence on digital communication systems operating over protocols with a wide frequency band. This is due to the small difference between the useful signal power and the noise in the upper region of the spectrum. In addition, the electromagnetic energy emitted by cable systems adversely affects the health of indoor personnel.

Crosstalk occurs between the pairs of wires due to the presence of capacitive and inductive coupling between them. The electromagnetic energy of the cables is also reflected due to the heterogeneity of their wave resistance and attenuated in the form of heat loss. As a result of attenuation, the signal power at the end of extended lines decreases hundreds of times.

Currently, 3 methods of shielding cable routes are practiced in the electrical industry:

- The use of all-metal boxes (steel or aluminum) or the installation of metal inserts in plastic. With increasing field frequency, the shielding ability of aluminum decreases. The disadvantage is the high cost of boxes. For long cable routes, there is the problem of ensuring the electrical contact of individual elements and their grounding to ensure zero potential box.

- Use of shielded cables. This method provides maximum protection, since the sheath surrounds the cable itself.

- Vacuum deposition of metal on a PVC channel. This method is ineffective at frequencies up to 200 MHz. The "blanking" of the magnetic field is ten times less than laying the cable in metal boxes due to the high resistivity.

Types of cables

There are 2 types of shielded cables:

- With a common screen. It is located around unprotected twisted conductors. The disadvantage of such cables is that large inter-cable interference occurs (5-10 times more than shielded pairs), especially between pairs with the same twist pitch.

- Cables with shielded twisted pairs. Individual shielding of all pairs is performed. Due to their higher cost, they are most often used in networks with stringent safety requirements and in rooms with a complex electromagnetic environment. The use of such cables for parallel installation makes it possible to reduce the distance between them. This reduces costs compared to split routing.

Twisted pair of shielded cable is an insulated pair of conductors (their number is usually from 2 to 8). With this design, crosstalk between conductors is reduced. Unshielded pairs do not have grounding requirements, they have greater flexibility, smaller transverse dimensions, ease of installation. Shielded pair provides protection against electromagnetic interference and high quality data transmission over networks.

, , . .