A pump is a rather necessary and useful thing in every house, especially in a private one. With it, you can pump water from the well, eliminate the effects of flooding in the basement and cellar, pump up the wheels and inflate the mattress for the arrival of guests. The scope of use of pumps and alluvial stations is quite large, modern manufacturers offer a wide variety of models, each of which has its own purpose. In the selection process, you should first focus on the type of pump, its purpose and, of course, those key indicators that characterize its effectiveness. The pump head is just one of these indicators. This is the second after productivity indicator of equipment utilization. Within the framework of this material, we will not only try to understand what the working pressure of a pump is, its value, but also calculation methods.

general information

A pump head is, from a scientific point of view, a pressure force created by its blades or pistons, necessary to push water or air through. The main unit of measurement for this indicator is meters. Do not be scared when you see just such a designation on the packaging - it has a scientific justification.

Flow and pressure: looking for the difference

Pump flow, pressure - these indicators are often confused. And here it is important to understand that the pump flow rate is the amount of fluid passing for it in a given unit of time, often represented by cubic meters per hour. Simply put, this is the ability of a pump to pump a specific volume.

Why exactly in meters

A pump for the pressure of water and any other liquid is a very popular device, without which it is difficult to imagine life in a private house. Many consumers still do not understand why the measurement of pressure is carried out in meters.

The pressure of a centrifugal pump, however, like any other, is usually measured in meters. Of course, such a system raises many questions. First of all, it happened historically, everyone has long been accustomed to such a designation and does not intend to change anything. Well, of course, it’s convenient, because you don’t have to resort to using other units of measurement, to make complex mathematical calculations. The head value, calculated in meters, gives us information that the pump can raise the liquid to a given height.

How to determine the required pressure

When choosing a pump, first of all, it is necessary to build on its purpose, the specifics of use and the main characteristics of its operation. The pump head is, by the way, the main characteristic that is indicated by the manufacturer in the instructions. Calculation of the pump head does not require special skills, special qualifications, even an average person can cope with it. It is clear that in many respects the design of the selected pump affects the calculation results. In each case, the result will be individual.

Submersible pump head

Submersible pumps are most often installed in deep wells, wells - in a word, where a self-priming pump simply can not cope with pumping water. Such a variety is very common today: the design is represented by a sufficient variety of models and modifications, each of which is able to satisfy all the needs of modern customers. Many experts strongly recommend purchasing imported pumps, but even among Russian companies there are quite worthy manufacturers whose products are distinguished by the highest performance, work efficiency and, no less valuable, affordability. During operation, the pump is completely immersed in water, and when the liquid approaches a critical point, it shuts off automatically until the water level rises to the required norm.

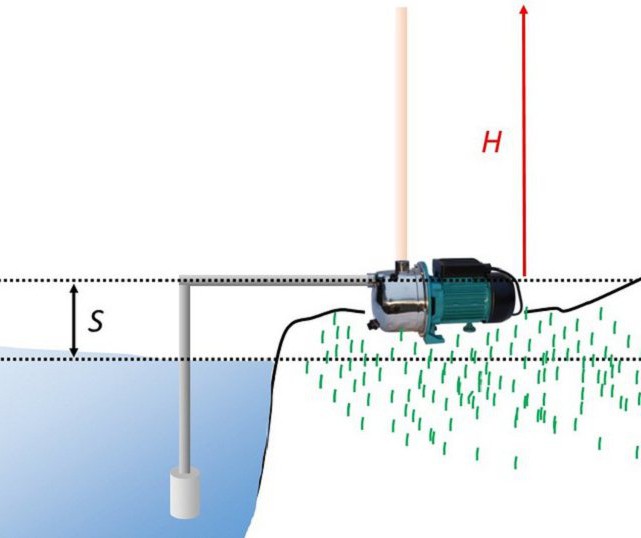

That is why one of the safest and most reliable is considered to be a submersible pump. Its pressure is calculated by the formula:

H = H height + H loss + H spout, where:

H height - elevation difference between the location of the pump and the highest point of the water supply system;

H losses - possible hydraulic losses that occur when the fluid moves through the pipe, they are primarily associated with the friction of the fluid on the pipe wall;

H spout - the pressure on the spout that allows you to use all plumbing fixtures (usually in the range of 15-20 meters).

Circulation pump head

We have already established that the pump head is the pressure necessary to push the fluid to a predetermined height. Circulation pumps found themselves in heating systems, it is with their help that uninterrupted circulation of the heat source in the system is ensured. Of course, it is necessary to approach the choice of a circulation pump more consciously and demandingly, understanding that the efficiency and uninterrupted use of it largely depends on this, which is so important for apartment buildings. Such pumps are reliable, efficient and have proven their worth even in apartment buildings. Of course, such a pump should also be selected based on pressure. The pressure of the circulation pump does not have any connection, and, accordingly, depends on the height of the building. The main thing here is the hydraulic resistance of the track. And here, for the calculation, the following formula is required:

H = (R * L + Z sum) / (p * g), where:

R is the loss;

L is the length of the pipeline, measured in meters;

Z sum - the total number by the safety factor for structural elements of the pipeline (for fittings and fittings this value is 1.3; for thermostatic valves - 1.7; and for mixers - 1.2);

p is the density of water, from the school course of physics we remember that it is 1000 kg / m3;

g - acceleration of gravity, the value of which is taken in the average value - 9.8 m / s2.

It turns out, knowing all the basic parameters to determine the pressure of water that you need in a particular situation, is quite simple, for this you do not have to attract specialists.

Can the installation affect the pressure

Given the simplicity, even the primitive design of the pumps, as well as the availability of detailed installation instructions, many modern men take up work on their own, that is, without the help of professionals. This behavior is most often associated with the desire to save money: not everyone is ready to pay not only for the pump or pump station, but also the services of the master. Given that the pressure of the pump is the main characteristic of its activity, no one is ready to lose. That is why the question begs itself: how much self-assembly can affect the pressure.

It would seem that we connect one pipe to the suction pipe, the other to the one that is responsible for the pressure, apply power - and you're done. In practice, the slightest mistake can not only negatively affect the pressure of the water, but also significantly reduce the duration of the work.

Basic installation errors

Let's look at the most common mistakes that many of us make:

- Diameter of the suction pipe. Quite often, the diameter of the pipeline in practice is less than the diameter of the suction pipe. This design, if connected, increases the resistance on the suction line side, thereby reducing the magnitude of the suction depth. In simple terms: a pipe that is reduced in diameter is simply not able to let in the size of the liquid that easily sucks and pumps the pump.

- Direct connection to a regular hose. Such a system is not particularly critical if a small pump is used. Otherwise, under the influence of a large pressure created by the pump, the hose will be compressed, its cross section will be significantly reduced, and water simply will not be able to pass through it. In the best case, this will lead to the interruption of the water supply, in the worst, to the breakdown of the pump without the possibility of subsequent repair.

- A large number of bends and turns in the pipeline. This installation option does not increase the resistance value, respectively, reduces the performance and pressure of the pump. That is why it is so important to bring the number of bends and turns to a minimum value if you want to use the purchased and installed pump to 100%.

- Sealing. It is due to insufficient sealing that significant water losses can occur at the suction section of the pipeline. Poor sealing not only reduces the pressure of the water, but also accompanies the pump operation process with excessive noise.

Subtleties of choice

So, if you are faced with the choice of a pump, both submersible and circulation, for the first time, we strongly recommend that you use all the tips and tricks. First of all, trust only trusted manufacturers whose product quality does not cause the slightest complaints. Do not neglect the help of professionals: they will help you choose the best option from the whole variety presented, starting from the basic requirements of the operating features.

To summarize

In the framework of this material, we examined what a pump head is, what affects its size, and how to independently calculate it. We hope that these tips and tricks will help you avoid fundamental errors and use the device 100%.