In modern construction, the mounting bracket is one of the most sought after materials. It has such advantages as versatility and ease of use, which makes it possible to use it even for non-professionals at home. Most often, the mounting bracket is used for joining structures made of wood. If work requires increased responsibility, then products with the mark “reinforced” are used, in which the strength characteristics are significantly higher than in ordinary ones.

A mounting bracket is one of the important types of fasteners with perforation used to fasten various elements to a plane at right angles. The main area of use of such elements includes the construction of wooden structures, including the installation of roofs, all kinds of ceilings, various decorative

elements, stairs and other things. Also, these products are appropriate to use when installing heating or ventilation systems,

assembling furniture and other things. Such an extensive area of use makes this material one of the most popular varieties of perforated fasteners.

The mounting bracket is appropriate to use for mounting a wide variety of elements that carry a different level of load - from decorative to capital parts of the structure. In this regard, this type of material has special requirements.

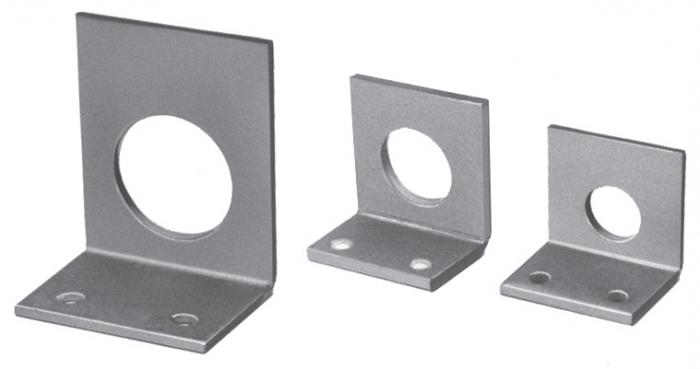

Narrow mounting angles are designed for mounting various lightweight structures, including decorative ones. Anchor elements are appropriate to use for fixing supports and pillars of wood to the foundation. Fixing beam angles are appropriate to use for joining timber elements, which can be load-bearing or auxiliary, as well as for creating frame-panel and frame houses. This suggests that these elements have certain properties and characteristics. The equilateral mounting bracket has become quite common as an element of roofing work, as it allows you to solve problems associated with fixing the main and auxiliary elements of the rafter systems. If the design is supposed to be exposed to additional loads, then it is best to give preference to reinforced materials. At such mounting angles , a stiffener is provided in the design , which allows them to withstand significant loads, guaranteeing a sufficiently long service life. In construction, an asymmetric mounting bracket is actively used, for which there are a number of special tasks.

All elements of this category have one common property - on both planes there are perforated holes of different diameters, which provides easy fastening by means of bolts, screws or screws of different sizes. Strengthening corrosion resistance is provided due to the fact that the manufacture of mounting corners is carried out from galvanized steel sheet. This provides the possibility of their use for connecting and fastening elements that are in the open air, as well as operated in fairly difficult conditions.