The bell-type furnace is a fairly common option for the construction of heating equipment, which almost reaches the channel product. This development can be called modern, it differs from its older counterparts in a new way of using hot gas.

Principle of operation

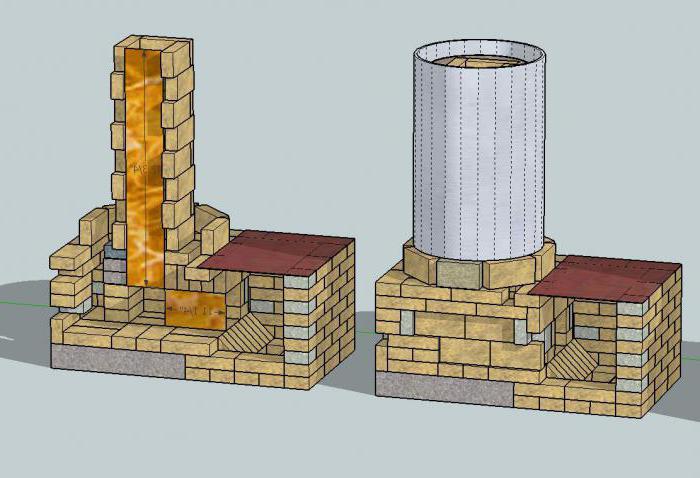

The mentioned design is not only equipment that heats the room, but also contributes to the effective retention of heat in it. The device is created in such a way that you can relax on it in cold weather, cook food if necessary. The principle of operation is associated with the creator Kuznetsov, which is why this furnace is also called the Kuznetsov furnace. The essence of the work is quite simple, it lies in the fact that hot gas circulates when exposed to the gravity of the gases, and not the exhaust pipe. In other words, gases that have a lower weight are collected under the dome of the hood, while the cold ones remain below, since they have a more impressive weight. Interacting, these gases form a zone of turbulence, due to this the walls are more effectively saturated with thermal energy. Gas is the main heat carrier in this case.

Key Features

The bell-type furnace has certain distinctive features, which are expressed in a high level of efficiency, ease of operation, multifunctionality, and also a very pleasant appearance. You can count on durability as well as high performance rates. A number of furnace owners, like many experienced professionals, believe that the described structures are one of the most effective and high-quality heating devices that have ever been created.

Preparation of tools and materials

If you will be building a bell-type furnace, you will need to prepare a shovel, a bayonet shovel, a cement-sand mortar, which is prepared in a ratio of 1 to 3, a timber formwork, and also a plastic film. In order to carry out reinforcement, you should stock up on a medium-sized rod.

Foundation construction

In order to build a base for the furnace, it is first necessary to prepare a foundation pit, the dimensions of which should be 150 x 100 centimeters. Dimensions are subject to change, however proportions should be maintained. A sand cushion is poured at the bottom, the thickness of which should be 15 centimeters. Such preparation should be left for 2 days so that the sand settles. This will create a design with higher strength characteristics. When creating the formwork, it is desirable to use plywood, but if it is not, then an iron door or boards can come up. This will not affect the quality of construction.

Specialist advice

If you will be building a bell-type furnace, it is important to pay attention to one important point, which is that the foundation must be completed in two bricks from the surface of the floor covering. The foundation should be poured in such a way that the surface is smooth as a slab. When forming the structure, you need to use a medium-sized rod, but you can also use a smaller rod, because the furnace will weigh a little.

Pouring technique

When Kuznetsov's bell-type furnaces line up, the foundation is poured slowly, periodically, the solution must be mixed with a shovel, which will get rid of air bubbles. This will increase the strength characteristics of the structure. After pouring, the base is left to harden, often it takes about 7 days. In some cases, it takes two weeks. Experts do not advise rushing, because the longer the foundation stands, the stronger it will turn out.

Ordering

The bell-type furnace, the order of which is presented in the article, should be laid out taking into account a certain technology. At first the foil is laid, only then can the brickwork be started. This will reduce heat loss, as hot air will be redirected back. The dimensions of such a lining should be slightly larger than the dimensions of the foundation, so that you can trim the edges. Bricks must be ground, they must be laid according to the pattern. Products are evenly spaced around the perimeter, and the side walls are laid out with a spoon, and you need to move from right to left. This will allow the master to see three bricks, 1 on the back and 2 on the right. When you lay out the second row, you should install the door for cleaning and blowing. The internal part of the structure will have such a form, thanks to which it will be possible to install it in any place, however, it is important to take into account the condition, which is expressed in the fact that the doors for cleaning should be located directly under the furnace. The third row is laid out in the same way, when laying the next row, you need to reduce the hole so that the remains of the burnt fuel fall off. In the far corner, a partition is made, which is designed to connect the lower and upper levels by the type of pipe. The next row is made using the same technology, but fire-resistant bricks should be used for the rim. A grate is formed on top. The sixth row will simultaneously be the first row of the furnace. From it it is necessary to remove the chimney to another compartment. When bell-shaped heating furnaces are built, the seventh row is laid out almost by the same method. Eighth row: you need to lay out the firebox with a simple brick, from the inside you have to cover it with halves of fire-resistant products.

Methodology for masonry work

For the inside of the combustion chamber in the tenth redoubt, whole bricks should be used, and at the eleventh it is necessary to install a lattice of fire-resistant products. When forming the next two rows, the grate must be removed, however, two chimneys will appear. On the fourteenth row, the chimney in the air compartment should be closed. To do this, it is recommended to use a metal plate, and the lower smoke box should be formed with a brick. Only one channel will go upstairs, which is left on the fourth row.

Second level formation

If you are building a heating bell furnace with your own hands, then on the fifteenth row you will need to add a fence plate. This element is strengthened on three sides with cement mortar. A brick is laid in the center of the smoke box, which will act as a column for the lid. Behind the stove, a sinus should be formed, which is necessary for moving gas into the chimney. Between 17 and 22 rows, access to the pipe should be blocked. The metal plate should be on the front wall of the oven, it will support the brick. For her, it is better to use forged rims. The next row is laid out in a similar way. When bell-type heating and cooking stoves are performed, another step should be formed in the 23rd row. The pipe and chimney are interconnected in a closed way. After 24 rows, which repeats the previous one, you can lay the pipe, its diameter should be equal to one brick. A collection plate is laid on it. After the completion of the work, the whole structure is covered with a roof, and then a brick pipe will go on . On this we can assume that the furnace is ready.

The nuances of masonry work

When laying out bell-shaped stoves with your own hands, you should consider that there are some tricks of masonry. If you follow the order, you will be able to get uniform heating of the levels of the structure and excellent traction. Instead, roofing material should be used specifically foil, which will improve heat saving due to reflective characteristics. If you want to increase heat transfer, then you should make levels in larger quantities. When the craftsmen lay out cooking bell stoves, observing all the rules and technology, they manage to get a design that is as warm as possible.

Before starting masonry, it is recommended to sand each product on its own, this will increase not only the aesthetic properties, but its brick functionality. The bell-type furnace is so called for the reason that the gas is as if under a bell. It is cooled in the same place, and after it is forced out by hot smoke down. In this part of the structure, smoke leaves the product, leaving in a special pipe. If you correctly perform the ordering, then the period of circulation of smoke will be minimized. The main feature of such a furnace is that it can be stacked as you wish. The main thing is to comply with the order, everything else will depend on specific circumstances.

Do not assume that with a smaller furnace you can achieve efficiency and compactness at the same time. This can affect the efficiency, which will fall sharply due to the square-cube law. Such structures are not made of metal, despite the fact that this could solve the issue of cleaning. We are talking about cast iron, which weighs quite a lot, but also has fragility.