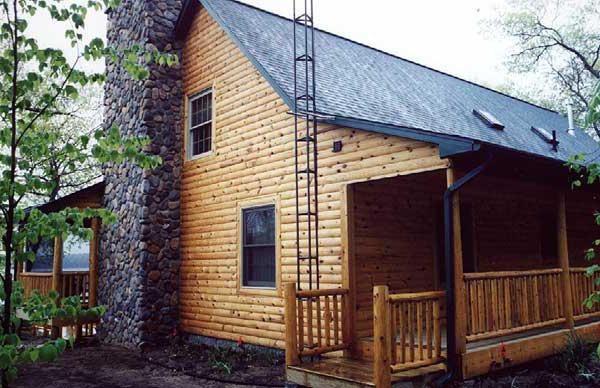

Glory to progress. Now we have the opportunity to decorate our home with wooden siding. Rather, metal siding with a tree view. What is the difference? The most important advantage of such a material as metal timber siding is that there is no need for preventive maintenance such as painting, grinding, impregnation, protection from insects, moisture, mold. In addition, metal is much more durable and stronger than wood, and situations characteristic of wood will not arise - the siding will not dry out under the scorching sun and will not swell from excessive dampness. All maintenance of the metal facade is extremely simple - washing with a sponge and soap or simply removing dust and dirt with a soft brush. Of course, upon closer inspection, it becomes clear that the “L-beam” siding is just an imitation of a wooden coating, but nevertheless, a building with this siding looks beautiful. Any frame house can be turned into a kind of elite, made of a log house, and it will come out much cheaper. The practical advantages of this material are also discussed below.

Facade decoration: buildings and materials that are used for this, their advantages and disadvantages

Now there are two of the most popular materials used for exterior decoration of buildings - plastic and metal. But the variation with a wooden coating is also good and takes place, therefore, imitators - a block house and a beam - are created. Below is a photo showing a metal siding for a block house, which is no less attractive in price and appearance.

The construction of a house made of natural wood is an extremely complicated matter, requiring a lot of knowledge and practical experience, while wall cladding using the same “L-beam” metal siding is easy, and, in fact, anyone can do this a landlord with hard-working hands and free time to carry out these tasks.

Why is there a L in the name of this siding

The name siding "L-beam" material received due to its physical shape characteristics. Siding in itself can be one-turning and two-turning. The second option is used specifically for the "L-beam", and its name came from the shape of the bend of the fracture.

"L-beam" - metal siding under a tree, properties

The thickness of the sheet of metal used in the manufacture is negligible - from 0.4 to 0.7 millimeters, which makes it light in weight and simplifies the installation process. But there is a negative side to this - with a point impact, the profile will be deformed and will not return to its previous form.

Having covered the metal with a protective layer of zinc, as well as with the polymer, as a result, a coating is prepared that is ready to serve for a period of fifteen to fifty years without losing its properties, with some adjustments for the sloppiness of a person, one or another for service.

The protective layer and the service life of the material - a direct correlation of factors

The longevity of the service that the L-beam siding will carry is primarily affected by the external protective layer of polymer. Polyester film, the quality and thickness of which they decided to save, thereby selling the skin cheaper, will be able to remain in full condition for up to fifteen years. The minimum acceptable film thickness in this case is 25 microns. Further on increasing - the higher the quality of the film, the more expensive the lining and the longer the service time. So, polyester with a thickness of 35 microns, which gives the siding a matte look, will provide you with a carefree existence in terms of the need to ensure a beautiful appearance for about 20 years. A pural with a thickness of fifty microns is characterized by the preservation of properties for up to thirty years, but plasistol (also a polyester derivative, so to speak) can withstand the sun, frost and wind for more than forty years.

Another great advantage that siding has a metal "L-beam" (wood) or the same "beam-house" - it can be of any length. When compared with plastic siding, which has a fixed length not exceeding four meters, the manufacturer can cut metal panels into any length by the customer’s order from half a meter to six. Thus, you can measure the length necessary specifically for your case, and decorate the facade with high-quality durable material practically without waste.

The cost of metal siding: what does it depend on?

Prices for siding "L-beam" directly depend on the thickness of the coating with polyester material, as well as, of course, from the manufacturer. It’s clear that branded options will cost more. The cheapest - 290-320 rubles per square meter (gloss 0.5 microns thick) and up to 490 rubles and more per square meter (plasmol coating).

What are the main points in the process of mounting siding

Installation of siding "L-beam" consists of three main actions. First of all, it is necessary to install the frame, to which the siding itself will be attached in the future. It must be smooth so that the final surface is smooth and without kinks. To do this, the level of the crate frame is adjusted using brackets, which sets the distance between the wall of the building and the crate. The second item is the installation of the starting profile, as well as parts that will frame the door and window openings, the corners of the building.

And the final step is actually fixing the siding panels to the frame. It is worth remembering an important detail: the slots for fastening at the panels are made oval for a reason. The goal in the first place is that when heated in the sun, the material has the opportunity to expand, move out a little, therefore it is not worth it to fasten tightly. Otherwise, the appearance of bulges that can deform the fasteners themselves, from which the coating will not be very ideal. For the same reason, during installation, they leave gaps of 2-3 mm on each side.

You can additionally insulate your building by covering the insulation with the same "L-bar"

Installation of metal siding "L-beam" may be accompanied by laying insulation. It is most convenient to use mineral wool slabs for this purpose. For this, at the first stage of fixing the battens to the brackets, put on these same plates, tightly pressing them to each other at the joints. On top of the insulation, it is necessary to lay a waterproofing layer, because mineral wool with high humidity loses up to 80 percent of its properties. Thermal insulation, together with insulation from moisture and water, is attached to the wall using dowels of the "umbrella" shape. Then the frame is fastened taking into account the need for a gap between the siding and insulation. The size of this gap should be about 5-7 centimeters - it will provide free air circulation in this area and will prevent the accumulation of moisture in the form of condensate.

Web material reviews

Unfortunately, right now it is not possible to find any detailed messages about the "L-beam". Either customers are grateful for the fast delivery, or for it, only slow, they scold. Regarding the quality characteristics, it is too early to wait for any comments, because sales through websites are still only gaining popularity in our open spaces, and the operational period is up to 50 years, so reviews about quality or compliance can be found a little later.