Choosing a pump for any purpose requires calculating its performance. It is convenient when the water pressure in the tap is regulated in such a way that at its highest value, splashes do not fly apart and at the same time do not have to wait long for filling a large container. About how to determine the performance of the pump, we will talk later in the article.

Pump Selection Parameters

There are two ways to obtain the optimal pump head: by artificial throttling or by the exact selection of device parameters. If you choose it according to the principle “the one that is next to your neighbor” is better, then there is a high probability of a low pressure of the jet with the simultaneous inclusion of several flow points. Or you will have to restrain the flow of water by partially closing the tap, which reduces the efficiency of the device, and therefore increases the cost of funds during its operation.

A professional approach to the issue of water supply requires taking into account many points:

- pump power;

- feed pipe thickness;

- trunk lengths;

- quantities and shapes of fittings;

- number of cranes.

Naturally, it is very difficult to foresee everything, therefore, with a complex system of plumbing communications, several pumps are used for greater efficiency. Each performs its function: one fills the intake tank from the well, the other provides the house with water, the third watered the garden.

Pump Characteristics, Head

Pumps have many characteristics. In order for the consumer to decide what type of device he needs, there are several basic indicators:

- Fluid flow rate, or pump capacity. It shows how much water a unit can pump over a certain period of time. It means that liquid flows directly at the outlet of the device. To determine the volume at the end of the line, it is necessary to subtract the pressure loss in the latter.

- The magnitude of the pressure, or pressure. Shows how high the pump can lift water. It does not take into account the height from the device to the level of the water surface.

- Height to water intake, or backwater. The distance from the water mirror to the outlet of the suction pipe is strictly determined - excess leads to the appearance of cavitation in the working space of the unit. This may change important characteristics of the pump or simply prevent it from pumping water. The back pressure can be increased by installing an auxiliary one in front of the main pump, right at the suction point. Exactly the same effect will be obtained when creating artificial air pressure inside the tank with the liquid.

- Power consumed energy.

Pump Overview

Pumps can be classified according to the principle of action, design features and purpose. There are also submersible and surface units. All of them are designed for pumping liquid, but most provide not only for it, but also for lifting water from different depths:

- Pumps for wells. Mostly submersible models. They are characterized by the fact that they can lift water from great depths (have no restrictions), depending on the power of the power unit. Create a powerful pressure in the pipeline.

- Drainers. They have higher performance, but are not intended to create high pressure, they do not give a high head. Convenient in that they can pump dirty water with small physical particles.

- Centrifugal. Universal pumps. They can be used both in wells and for pumping fluid from reservoirs. They do not sink into the water and have a restriction on the distance from the surface of the water surface to the entrance of the suction pipe. The pressure of the pump depends on the number of impellers and engine power, but still they cannot raise the column of water higher than 120 meters.

- Whirlwind. They look like centrifugal ones, but the impeller is organized differently here. With lower engine power, they provide high head and performance. Raise a column of water over 160 m. The disadvantage is the demand for its purity.

- Circulating. They do not raise water from the depths, but also create a certain pressure and work at elevated temperatures.

Pumps: feed, pressure

Maybe not everyone knows, but the pumps are paired with atmospheric pressure. They simply create an area of discharge and discharge. Therefore, no matter what efforts we make from above, using the most powerful units, it will not work to raise water from a great depth. As soon as the force of air pressure is balanced by gravity, the water in the pipe will stop. Powerful submersibles that create pressure are used to lift from the depths.

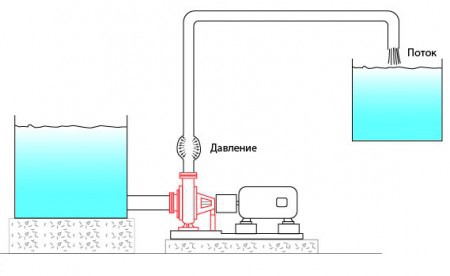

The main characteristics of the described units are the pump head, performance. They have a certain relationship between themselves. So, by pressure we mean the ability to supply water to a certain height or to move in a horizontal direction to a given length. It is clear that the same pump will give out different pressures at heights of 20 and 120 m.

The pressure must be known, choosing the type of pump. Each model can create strong or weak pressure, which is due to the design of the working mechanism. When a liquid comes into contact with a wheel blade or a membrane or a piston, it receives a certain charge of kinetic energy, which lifts it up.

The most efficient centrifugal systems with multiple sequential impellers. They are high-pressure pumps and have a very high efficiency.

How to adjust the pressure

In any complex plumbing system, it is necessary to regulate the pressure created by the pump. There are four ways to influence pressure:

- Throttling. The essence of the method is that a special choke is installed at the output of the device or at the suction pipe. An ordinary crane can play its role. At the installation site, depending on the diameter of the throttle hole, a part of the pressure is extinguished. With the position of the water flow limiter at the pump outlet, the efficiency of the device decreases, since when the pressure decreases in the electric power system, the pump consumes the same amount.

- Electric regulation of the speed of rotation of the impeller. This is the most efficient method without losing pump efficiency. Water supply decreases with a proportional decrease in power consumption.

- Mechanical speed reduction. In this case, a reduction gear is used. The method is economically disadvantageous because the engine consumes the same power and an additional mechanism is needed - a gearbox.

- Bypassing. A jumper is placed between the outlet and the suction pipe of the pump. It turns out that part of the fluid simply circulates in a circle, without doing useful work. As a result, the pressure in the pipes drops, and the efficiency decreases.

What will be the pressure at the pump pumping water from above

When the intake tank is located above the installation site of the pumping system, practically no energy is wasted on suction. Then, to calculate the pump head, use the following formula:

Ntr = Ngeo + N loss + Nsvob - Low tank.

Ntr here - the necessary pressure value, due to the costs of the consumer.

Ngeo - level difference between the pump installation platform and the highest point of water consumption.

Loss - loss of overcoming friction in the supply line with the exception of the vertical pipe section from the supply tank to the pump.

No freedom - the pressure from the points of consumption when fully opened.

Tank low - the height value between the tank and the pump.

Water injection from the depths

How to determine the pump head when pumping water from a well, water storage pit or well? The calculation formula takes the following form:

NTR = Ngeo + N loss + Nsvob + Level of the source.

In it, all the terms are the same, except for the last one - Level of the source - which is the difference between the liquid suction point and the pumping device.

What is a pumping station

The pumping station is a system of a pump and a hydraulic tank, working in pairs. Plus, there is a special pressure control relay. The hydraulic accumulator here serves as an element smoothing the pressure of the pump, preventing the frequent turning on of the electric motor and leveling out possible hydraulic shocks in plumbing communications.

Stations can be based on any type of pump, using any battery capacity. The larger the tank, the stronger the additional lift created by it.

Conclusion

When the water pressure in the pump is insufficient, you can get out of position by installing two or more units in series. Such a scheme is often used for deep wells, where a submersible unit is installed at the bottom, which supplies water to the centrifugal suction pipe.