If you like to eat fresh natural vegetables grown in early spring, enjoy the fuss in the beds, and besides, you have plenty of free time, you should consider devoting yourself to farming. Be that as it may, but so that your work is not wasted, and the harvest is always pleasing with its abundance, you will have to acquire a greenhouse without fail. Forget about broken window panes and torn pieces of cellophane. In the modern construction market, there is absolutely perfect material for the construction of greenhouses. It's about polycarbonate. Read the article to understand what kind of material it is, how to choose it correctly and what criteria to consider when buying. You can also figure out what is the best polycarbonate thickness for a greenhouse.

Main characteristics

What thickness to use polycarbonate for a greenhouse, you will learn later, but now it’s worth talking about the material itself and its properties. The chemical composition and technology of melting the granules will probably be of little interest to you, but the basic qualities for domestic use must be known. First of all, polycarbonate is stronger than glass, not to mention a plastic film. It perfectly transmits light and, importantly, protects plants from ultraviolet rays.

The material has excellent thermal insulation characteristics and practically does not burn. It is used over a wide temperature range: from -40 to +120 . The sheets are not subject to corrosion, moisture resistant, durable. Due to their ductility and light weight, they are quick to assemble and easy to handle. At the moment, there are two types of such material on sale - cellular and monolithic. Both one and the second type can be used in the construction of greenhouses.

Monolithic polycarbonate

Monolithic polycarbonate is a one-piece monophonic material like glass. It has increased strength, well resists shocks, withstands large snow loads. Available in the form of standard sheets:

- width - 2.05 m,

- length - 3.05 m.

The thickness of the polycarbonate for the greenhouse can range from 2 to 12 mm. The most acceptable is 4-6 mm.

Cellular Polycarbonate

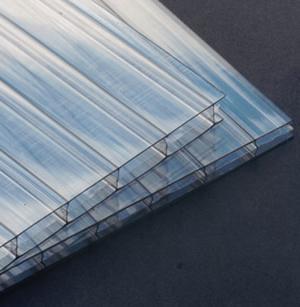

Cellular (cellular) polycarbonate is made of two, three or more sheets of material to reduce the total weight and increase the thermal insulation properties. They are welded together using stiffeners so that there is a layer of air inside. Such polycarbonate is produced in sheets with standard sizes:

- width - 2100 mm,

- length - 612 mm.

The thickness of the material can be 4-32 mm. Depending on this indicator, cellular polycarbonate has a different distance between the stiffeners - from 5.7 mm to 20 mm. Bending radii also differ: the thinner the material, the more it can be bent. For example, for polycarbonate-six it is equal to one meter. This is useful to you if you decide to make an arched type greenhouse.

Cellular polycarbonate is also different in a typical, structural structure. This refers to the number of sheets welded together and the angle of installation of the ribs. There are five main types of this material: 2R, 3R, 3RX, 5RX, 6RS.

Material color

Available are transparent, white, green, red, yellow, blue polycarbonate sheets. Less often you can see the color of opal and bronze. For the construction of greenhouses, the color of the material does not matter much. You just should not get carried away with too dark shades, it can negatively affect the plants.

A little about the thickness of the sheets

The thickness of the polycarbonate for the greenhouse affects the light conductivity, heat conservation and UV protection (the so-called UV factor). If you look at the sheet at a certain angle, you will notice a bluish tint on the plane. This is the protective layer. This indicator does not play a big role, unless you intend to grow specific exotic vegetables and fruits. Depending on the size of the sheets, UV protection varies between 3.9-2.4 units. The recommended polycarbonate thickness for the greenhouse is 4-6 mm, for complex structures - 8 mm, and for using the structure in the winter - at least 10 mm.

How to choose a material

So, you want a greenhouse, no matter which one - stationary or prefabricated. The most correct decision would be to order it directly from a company engaged in the manufacture and installation of these same structures. And they simply must know what thickness polycarbonate is better to use for a greenhouse. By doing so, you will not only be able to avoid mistakes during construction, but also blame the manufacturer on the quality of the material.

Keep in mind that the company must provide a guarantee for both polycarbonate itself and the greenhouse in general. The longer the warranty period of the design, the stronger and calmer your sleep. If you heeded the advice, then you can not read further. You just have to harvest the crops grown in this greenhouse, and in case of any defects, call the manufacturer and demand their immediate elimination. If for some economic reasons or because of your hard work you still decided on a difficult independent construction, welcome to the store.

First of all, choosing polycarbonate, ask to show all available documents. No such - fake, do not buy. There are not enough fasteners or different colors of the docking and end strips - we don’t take it. We observe swelling or damage to the protective film - to the side. There is no marking on top and at the ends of the sheets - let them keep it for themselves. Do not be afraid to ask sellers questions, ask your department consultant what polycarbonate thickness for a greenhouse is better. At the same time, remember that it’s their business to sell, and then you will suffer from poor-quality goods.

Polycarbonate Requirements

So what material to buy, what thickness polycarbonate is better to use for a greenhouse? It all depends on your desires and capabilities. The main criterion is strength. For a temporary greenhouse, you don’t need to spend much money - you can take polycarbonate “four”. Allow funds - buy a "six". The thickness of the polycarbonate for the greenhouse, the use of which will last more than one season, respectively, should be greater.

You can make a combined version of the design, where the roof will be of a monolithic, and the walls of a honeycomb type of material. There are structures where whole sheets are let down to prevent mechanical damage. The best polycarbonate thickness for a greenhouse is one that can withstand all natural disasters: wind and hail, frost and snow. In this regard, do not skimp, it is better to choose with a margin of safety.

It does not matter what thickness polycarbonate for the greenhouse you bought, you need to remember that this material is subject to temperature. It expands in the heat and narrows in the cold. Installation must be carried out taking into account this factor. If possible, try to make the greenhouse sheathing itself out of small sheets, since it will be easier and cheaper to replace them in case of damage. And buy materials from proven, well-established manufacturing companies. Let your greenhouse serve for many years and please you with plentiful harvests.