From ancient times, man tried to protect himself and his family from external aggressive factors, whether it be cold or heat, rain or snow, wild animals or harmful neighbors. Therefore, it is not surprising that over the millennia innumerable materials have been tried as protective fences and ceilings - from stone, clay and straw to forged gratings, concrete blocks and profiled roofing.

Brief description of the main types of roofing

Let us briefly compare the most common materials used today for these purposes. As before, the slate on a cement basis, more often - a wave, less often - a flat one, remains our "leader in hire". This is a wonderful, budget-proven option for decades - both for equipping a roof and for installing a fence (rather fragile, darkening over time, not allowing bends and terribly banal).

Ceramic tiles - stylish, durable, as they say, for centuries (high price, increased load on the rafter system due to the large weight, requires professional installation).

Euroroofing material - inexpensive, easy to install, reliable (not stylish, not durable, high quality requirements for the surface to be coated, most often used for industrial ceilings).

Flexible bituminous tiles - excellent appearance, durability, arbitrary roof geometry, ideal for arranging the roof (high price of the material, qualified installation, strict requirements for the surface of the base).

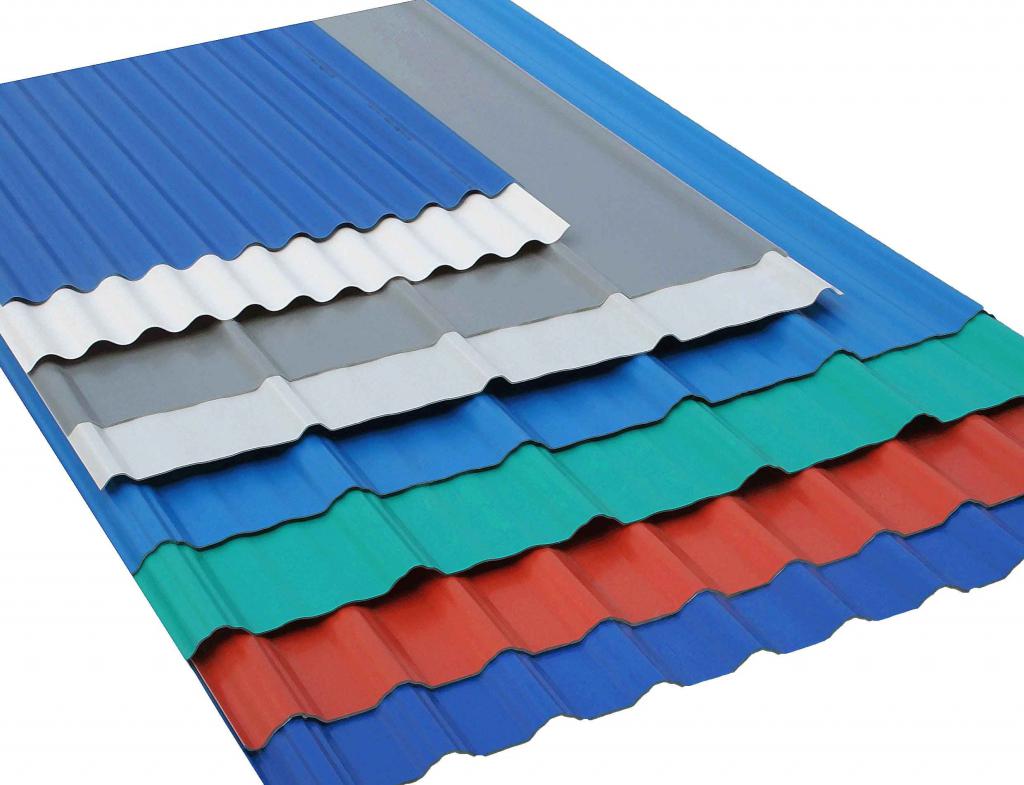

The metal tile is aesthetic, lightweight, easy to install, is available in a wide range of colors, with proper styling for decades it retains its characteristics (it makes noise during rain and hail, additional measures are necessary to protect it from wind pressure, there is a high probability of damage with a concentrated load).

Another widespread roofing material is corrugated board. This is the “sibling” of the metal tile, which has the same advantages, but is less demanding on wind protection, more stable forcing, has a lower price, and in addition, it is an excellent material for creating a fence.

There is still a mass of specialized and universal materials for forming fencing and roofing, which are able to satisfy the most demanding needs, but if we talk about the balance of price and quality, then, undoubtedly, among the leaders are various types of roofing sheeting.

Professional List - General Description

Let us consider in more detail the main characteristics and possibilities of using a profiled sheet as an element that plays a key role in the proper functioning of the roofing system as a whole. It is advisable to use roofing sheeting for the roof with an angle of inclination of the slope to the horizon of at least 8 °. Structurally, the material is a hot-zinc (strip) metal sheet, usually with a polymer coating applied to it, having a predetermined corrugation geometry and a capillary groove that prevents moisture accumulation at the joints of the profiled sheet joints. Depending on the requirements for the quality of the surface to be covered and the expected snow load, the thickness of the roofing sheeting can vary from 0.3 to 1.5 mm, and the height of the profile from 8 to 114 mm. Sheet rental is carried out on specialized equipment, while, according to the technical conditions, it is possible to produce corrugations of various geometric shapes.

Decoding of the marking of the profiled sheet

The dimensions of the roofing sheeting are standardized and are reflected in its marking. The first is the letter designation characterizing the scope of the profiled sheet.

- C - wall, used for wall cladding and fencing (fences).

- N - bearing, used for roofing, without deformation can withstand human weight and snow pressure, if necessary, it can be reinforced with stiffeners.

- NS - professional sheet mixed purpose.

The numbers following the letters inform about the wave height in millimeters, and then data on the sheet thickness are presented.

Two final sets of numbers give information about the size of the roofing sheet of the corrugated board, its installation width and the possible maximum length.

Thus, knowing the marking, it will not be difficult to determine the main parameters of the profiled sheet. For example, the marking 35-0,5-1000-6000 will mean that we have before us a universal (roof-wall) corrugated board with a wave height of 35 mm, half a millimeter thick, an assembly width of 1 m with a possible maximum sheet length of 6 m.

Parameters of the profiled sheet MP 20

The most common standard size is the MP 20 roofing corrugated board, which is associated with a combination of the ideal compromise between weight, bearing capacity, aesthetic appearance and its price.

This type of professional sheet has a trapezoidal profile shape and is made in three versions - A, B and R, where the first two modifications are used as a fence, and the R modification is designed to protect the roof. Type A has a predefined front (polymer coated) side, while in option B the painted surface (or even both) is determined by the customer. The base of the trapezoidal profile of the MP 20 roofing sheeting is wider than the top, which provides additional resistance to static loads. For wall modifications, the inverse proportion is used, which is more effective in resisting dynamic wind pressure.

Geometrical dimensions

The size of the roofing sheeting refers to the key parameters that determine the need for the amount of material for the planned work. It should be understood that it is economically feasible for manufacturers to use one sheet size (as a rule, this is galvanized steel coil 1250 mm wide), and the width of the finished profiled sheet at the output will depend only on the wavelength. Because the higher the height of the corrugation, the correspondingly smaller the sheet size will be. For example, for the C8 brand it is 1200 mm, and for the C75 of the same material the width will be 800 mm. Modern rolling mills are able to produce roofing sheeting up to 14 m long, but the most optimal for transportation is a size of 6 m, and it is much more difficult to install sheets of greater length, and if we talk about building a fence, it is also pointless. Therefore, a professional sheet, as a rule, is cut in strips of two, two and a half or three meters long.

Features of calculating the need for sheets

If the task is to cover a flat pitched roof or mount a fence, then the calculation of the need for profiled sheets is calculated by simply dividing the total overlap surface by the useful area of the roofing sheeting with rounding up. This parameter differs from the pure geometric dimensions of the sheet and is calculated by multiplying the mounting width of the sheet (taking into account the horizontal overlap) by its length (for the roof - taking into account the vertical overlay). Moreover, the smaller the slope of the ramp, the more there should be an overlap. If the angle is less than 14 degrees, then two corrugations with a vertical overflow of at least 200 mm are allowed on a horizontal overlap, with a greater steepness of the roof, the lock can be one wave with the top sheet entering the lower order of 100-150 mm.

Formation of eaves and frontal overhang

In addition, the overlap sheet should somewhat extend beyond the overlapping surface, forming a kind of visor called the eaves and front overhangs. This is done to protect the walls of the building from the effects of precipitation. The magnitude of the overhang depends on the type of corrugated board, the type of wind protection (wind board or plank) and the subsequent use of the gutter to drain water from the roof surface. For a thin sheet with a small corrugation depth, this size is from 50 to 100 mm, and for materials with a large cross section and profile height, an overhang of up to 200-300 mm is allowed.

In order to accurately calculate the requirements for the amount of galvanized roofing sheeting, a drawing of the future roof is drawn and sheets of affordable size are schematically placed on it taking into account dormers, ventilation pipes and other protruding elements. Here we apply the general approach, which implies the purchase of material 10-15% more than the calculated. This is done for insurance, when the work can be stalled due to lack of one or two sheets damaged during installation, a possible defect in the material or other force majeure situation.

Calculation of the weight load of the roofing

Another basic characteristic that affects the design of the roof of the building as a whole is the weight of the roofing sheeting (specified by the seller), where the measure is one square or linear meter of material. It depends on the thickness, width and specific gravity of the galvanized sheet, as well as the height of the corrugation. For the most popular brand MP 20, the weight of 1 m 2 is 3.87 kg per sheet thickness of 0.4 mm and 7.3 kg at 0.8 mm. For thick-walled brands with a high profile, the weight can reach up to fifteen and a half kilograms per square meter.

Roof protective functions

Playing the role of a protective barrier, the roof is designed to counteract a number of aggressive factors that arise as a result of negative influences both outside and inside the room.

The mechanical characteristics of the profiled sheet should provide the required protection of the roof from the load caused by the influence of precipitation, primarily compensating for the pressure of the snow cover.

The polymer protective layer, in addition to the aesthetic component, is designed to protect the sheet from corrosion processes caused by chemically active particles in the air, eliminates temperature differences, and also resists solar radiation activity.

Reliable fastening of the corrugated board to the crate solves the issue of wind pressure.

Moisture protection requirements

From the bottom of the profiled sheet, it is necessary to provide a hydrobarrier that protects the wooden base of the roof from mold formation, and the insulation from getting wet, due to condensation or moisture at the joints. During installation, it is important to provide for natural ventilation, which allows for high-quality moisture removal. Wind traction is created by means of inextricable air channels formed from the cornice (low pressure zone) to the ridge (high pressure zone).

The order of installation of the profiled sheet

The roofing corrugated board is mounted in rows, taking into account the wind rose, from the extreme lower point of the ramp (taking into account the eaves and frontal overhang) upward, with an overlap with adjacent sheets, both horizontally and vertically. At small angles of inclination of the roof (less than 12 °), in order to avoid leaks, the joints should be sealed with silicone glue.

The profiled sheet is fixed on the crate of a wooden beam with a step depending on the height of the profile and the slope of the roof slope. If the angle is greater than 15 °, then the step should be 35-50 cm, and with a smaller slope and depth of the corrugation less than 20 mm, the crate should be continuous.

Ways of fixing corrugated board

The corrugated board can be fixed with self-tapping screws or even simple nails, however, the possibility of corrosion and roof leakage is not excluded. Therefore, it is more advisable to use special self-tapping screws designed to fix to the base of the profile sheet and metal tile. They are equipped with ethylene-propylene rubber gasket, which provides reliable sealing of the mounting hole from the self-tapping screw, without interfering with its main task - reliable fixation of the roofing. The length of the fastener is selected based on the thickness of the sheet, the height of the washer gasket and should provide reliable fastening of the corrugated board to the crate. In addition, the screw heads can have the same color coating as the fastened material, thereby not spoiling the appearance of the roof. At the end, they have the shape of a drill, easily penetrate through the thin metal of the profiled sheet.

To avoid the appearance of gaps, it is necessary to screw them in strictly perpendicular to the base, avoiding distortions along the lower (adjacent to the crate) surface of the wave.

Additional elements for mounting a profiled sheet

When forming the ridge and in the case of adjoining the corrugated sheet to vertical surfaces, external and internal angular strips (shelf width 150-200 mm) are used based on the same material and coating as the profiled sheet, mounting them with an overlap of 100-150 mm.

Properly mounted roof from corrugated board is able for many years to provide comfort and beauty of your home.