To understand what constitutes a plunger pump, you must first decide what category it can be attributed to. Quite often in everyday life there is a need to mix several components of the solution in a specific ratio. Typically, a metering pump is used for this purpose . It is a hydraulic device that allows you to mix and meter liquid substances. By the specifics of their work, such pumps are divided into volumetric and volumetric. Their difference lies in the special container in which the liquids supplied for mixing are located.

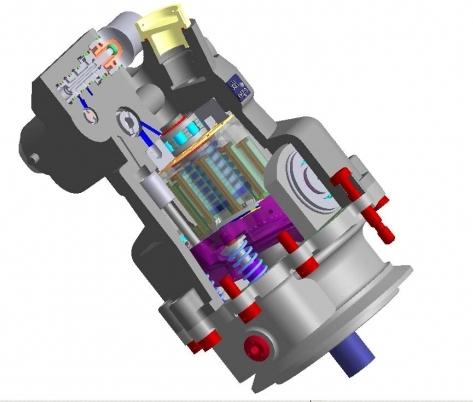

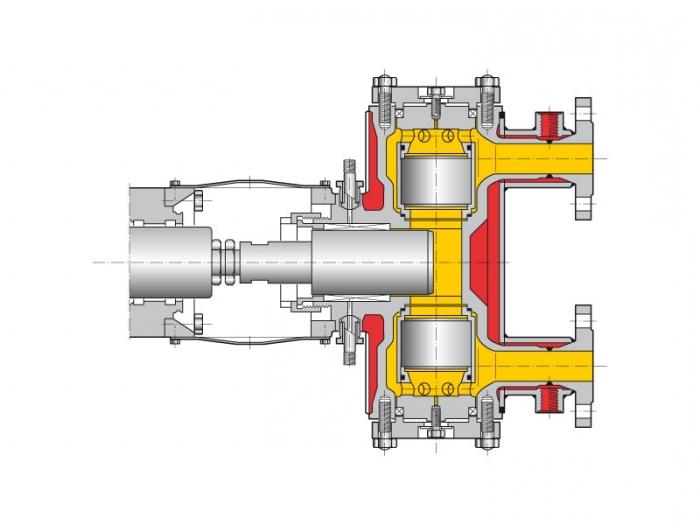

There is such a variety as a plunger pump, which belongs to the category of volumetric. By their specifics of work and structure, such devices are similar to piston ones. The main difference is in the features of the plunger, that is, a special piston. It is a metal rod moving in the working chamber of the metering pump reciprocatingly, while it does not interact with the walls. The plunger is the main element for the operation of the plunger pump. In this regard, a number of specific requirements are made to it: it must be durable, tight, wear-resistant, ensuring high-quality and reliable operation of the pump. The cost of the device depends on what materials it was made of.

The plunger pump has a certain specificity of work: when the plunger moves to the right side, the pressure in the working compartment is significantly reduced, and the pressure in the suction pipe stably remains high. When a difference in pressure is formed, the suction valve starts to work, with the help of which the fluid moves into the working chamber of the pump. When the plunger moves to the left, the opposite pressure change occurs, due to which the discharge valve opens, which displaces the liquid from the working chamber.

The plunger pump through such a change in pressure creates a certain ripple. This can adversely affect

the operation of the device, so the problem should be fixed. You can use several plungers that are connected by a shaft, while they must move cyclically, however, each cycle must differ from another angle and phase of movement. Another option involves the creation of opportunities and conditions for the differential operation of the pump, in which pumping is performed while the valve is moving in any direction.

Plunger pumps for water work on the same principle as conventional ones. The volume of pumped liquid here depends on what pressure is created inside, that is, the higher it is, the more substance passes. The design features of the devices allow us to divide them into several categories: single and multi-plunger; with a heating jacket, without it, with cylinder sealing; with manual or automatic control; horizontal or vertical; single and multi-cylinder. High pressure plunger pumps are able to work with different types of fluid, and therefore they are made from different materials, depending on the working medium used.