One of the best models of household inverters is the Terminator welding machine . It is characterized by low weight, compact dimensions and a wide range of functions, which allows not only to carry out welding work, but also to cut metal. Thanks to this, the inverter has become widespread among professionals and ordinary consumers.

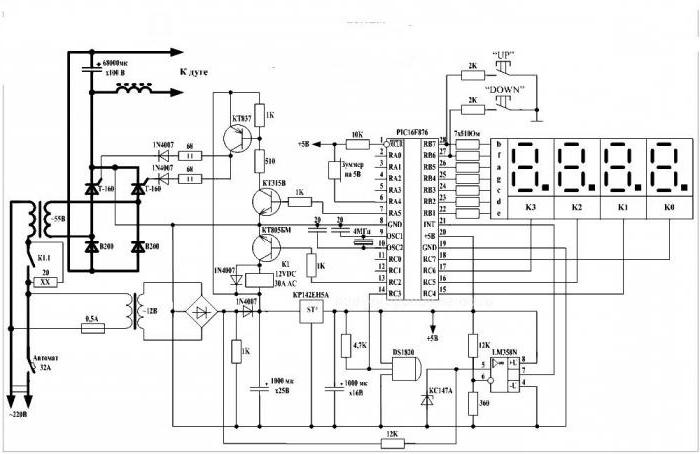

Scheme of the welding machine "Terminator"

The inverter power unit is capable of generating only direct current. This is due to the fact that the electrical circuit of the Terminator welding machine is based on a rectifier. The characteristics of the welding current affect the mode and operating conditions of the equipment:

- MMA mode, designed to work with bar electrodes on structural steel.

- Low carbon steel cutting mode.

The inverter can be used as a charger for the car’s battery or as a starting device for the vehicle’s engine thanks to the integrated unit.

Scope and purpose

Due to its multifunctionality and compact dimensions, the Terminator welding machine is in demand not only among ordinary consumers, but also among professional craftsmen. The inverter is most effective in those operating conditions that require equipment mobility. In most cases, the Terminator welding machine is used by welders working in the public utilities, construction, or repair teams.

Inverter Functionality

The equipment of this brand has the following functions:

- Welding by piece electrodes of products from low carbon steel.

- Cutting low carbon steel products.

- Charging the rechargeable batteries due to the alteration of the Terminator welding machine due to the integration of the launcher and charger in it. This feature is beneficial for car owners: they can quickly and easily start the vehicle engine.

Features of the technique

The inverter has a simple design, small dimensions and light weight, making it easy and convenient to use in a domestic environment. The control of the welding machine is intuitive and simple.

The Terminator welding machine is characterized by a number of features that make it an indispensable assistant in everyday life when performing various welding operations:

- Forced cooling system integrated in the inverter housing. It allows you to operate the device for a long time without the need for breaks to cool the internal elements and parts. When the device overheats, it automatically turns off.

- The current-carrying tires and the transformer winding are made of a special copper alloy that can withstand high electrical loads, so that welding machines can be driven for a long time without interruptions.

- Economical energy consumption is another advantage of the Terminator welding machine and the reason for its popularity among professional and novice welders. You can connect the device to a standard single-phase 220 V network without the use of additional equipment.

- Simplicity and ease of use of the inverter facilitate welding. You can transport the device from place to place thanks to special belts, which allows you to use it when working at heights.

- A high degree of safety is another advantage of the inverter. The casing of the device is protected from electric shock by the user, and a forced ventilation system prevents overheating of the device during long-term operation.

Inverter Benefits

The welding machine "Terminator" is made by the Russian company. The developers combined the classic rectifier in the models of this brand with innovative technical solutions, on which the advantages and disadvantages of the device depend.

The advantages of the inverter are determined by its following structural features:

- Block rectifier responsible for forced cooling of the welding machine. This design solution allowed to increase the duration of the device to almost 100 percent. Not all professional inverter models can boast of such parameters.

- The power unit can operate from standard single-phase networks. This feature excludes the device from the category of professional models powered by three-phase networks, as indicated in the instructions for the Terminator welding machine. Due to the ability to connect to household electrical networks, the inverter has gained popularity among consumers.

- Power parts of the device design are made of a special copper alloy, which is most often used in professional models. Thanks to such a solution, it was possible to combine professional characteristics and domestic use in one device. The disadvantage is that the weight of the device has increased to 13 kilograms, while similar models weigh an average of 6-8 kilograms. The disadvantage, however, is easily covered by almost one hundred percent duration of the inclusion.

- Simple device control circuit. The inverter implements two to three operating modes, which are enough to solve everyday problems. The absence of additional functions and third-party regulators and switches simplified the work with the welding machine and made it possible for beginners to use it.

Disadvantages of technology

Among the minuses of the Terminator welding machine are the following:

- the impossibility of its transfer to AC mode;

- only one type of welding - MMA;

- production of a small welding current, due to which a restriction is placed on the electrodes used.

Welding machine "Terminator 175"

The inverter "Torus-175 Terminator" is used for welding using piece MMA electrodes or TIG welding with tungsten electrodes. A shoulder strap is supplied with it, which makes it easy to transport the inverter around the job site. Built-in protective system protects the device from overheating. The conversion coefficient of the device is high, which saves energy during operation. Even in conditions of surges in the input voltage, the stability of the welding arc is maintained.

The complete set of the welding machine includes cables and sets of wires of the Russian production. All items are factory tested. It is not recommended to carry out independent repair of the Terminator welding machine, since this removes the device from warranty service.

Model benefits

Inverter "Torus-175 Terminator" has the following advantages:

- Compact size and light weight, which facilitates its transportation.

- Resistance to sudden surges in voltage.

- Create high quality welds.

- Built-in microprocessor that controls the inverter.

- The possibility of continuous operation without overheating.

- Automatic shutdown of the inverter when it overheats.

- Welding wires are supplied.

- A special plug is sold with the inverter.

Welding machines "Terminator" - household inverters for welding at home.