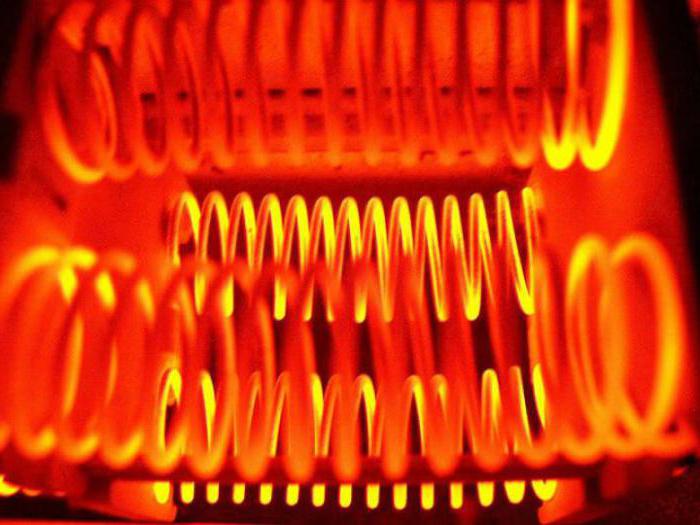

It is impossible to imagine modern life without a huge number of various electrical appliances. For many of them, the nichrome spiral is the main detail - the "heart" of the mechanism. The operation of electronic devices, machine tools, and electric tools used in everyday life and in large-scale productions depends directly on the wire with the original alloy.

Description

In 1905, the American scientist Albert Marsh invented to combine chrome and nickel. The patented formula looked like 20% chromium and 80% nickel. The alloy was called nichrome. Initially, the mixture did not have ligatures (refractory elements) and it was a two-component alloy. Today you can find options with a nickel content of 55%, and chromium from 15%. The impurities are: iron, silicon, manganese, aluminum, titanium, molybdenum, silicon. More than ten “recipes” of metal are known that fall under the designation Nichrome.

The nichrome spiral, having an exceptionally high resistivity, has become an indispensable component in numerous tools and instruments. It is able to withstand high temperature oxidation in both conventional and aggressive conditions. This property of the alloy is due to the presence of chromium, which forms a protective oxide film on the surface of the product. She also paints the alloy in a dark color. If you remove (by mechanical action) the oxidized layer, the shade changes to whitish-gray.

A two-component alloy lacks magnetic characteristics; multicomponent modifications may have weakened indices. The nichrome spiral is stiff and good ductility. The wire is available in various cross sections from 0.01 to 10 mm. Basic properties:

- electrical resistivity - 1100-1400 OM`m;

- melting point up to 1400 degrees (working range - 800–1100 degrees Celsius);

- density - 8200-8500 kg / m 3 ;

- strength - 650-700 MPa.

Material properties meet the highest technological requirements.

Benefits

The high and steady demand for nichrome components is explained by the amazing qualities of the alloy:

- not subject to corrosion;

- light weight;

- easy to process (easily stamped and welded);

- possesses high heat resistance;

- strong and at the same time elastic;

- differs in the increased resistance to hostile environment;

- has a long service life.

Another important advantage is the increased resistance to electric current. In practice, this indicator allows for a smaller amount of nichrome (the length of the nichrome spiral is shorter) to get more heat than, for example, from a steel element. In turn, a smaller amount of metal can reduce the weight and size of the entire apparatus. The most important advantage of nichrome is the combination of all of the above indicators in one material.

Varieties

A nichrome spiral can be made of various modifications of the alloy and be of different thicknesses. Stamps differ in their composition and are divided (conditionally) into three main groups:

- For resistors: X20H80 (20% chromium, 80% nickel); X20N73YUM-VI (20% chromium, 73% nickel, 3%, aluminum, 1.5%, molybdenum, up to 0.3% manganese, up to 0.05%, titanium, 2%, iron, up to 0.05% carbon melted by vacuum induction method).

- For use at temperatures not exceeding 900 degrees.

- For heating elements with increased resistance to high temperatures: 70- (27% chromium, 70% nickel, 3% aluminum, up to 0.3% manganese, up to 0.03% cesium, up to 0.1% barium, up to 1, 5% iron, up to 0.1% carbon).

The properties of the alloy depend on the proportions of its constituent components. A large amount of chromium prevents oxidation.

Scope of application

Among the most popular material in the market of electrical products is nichrome wire. The spiral of this alloy is used in many models of electric heaters. At home, craftsmen use it for:

- wood burning apparatus;

- homemade ceramics kilns;

- devices for the rapid heating of certain metals in the forge;

- the manufacture of simple heating structures ("goats");

- home-made welding machines.

The industrial use of nichrome in household appliances is wide: hair dryers, irons, heaters, soldering irons, electric stoves and more. A wire with a large cross section is used for automatic welding machines. Such an alloy can be found in laboratory equipment and the radio engineering sphere. Nichrome is used where resistance to high temperatures and aggressive environments is required.