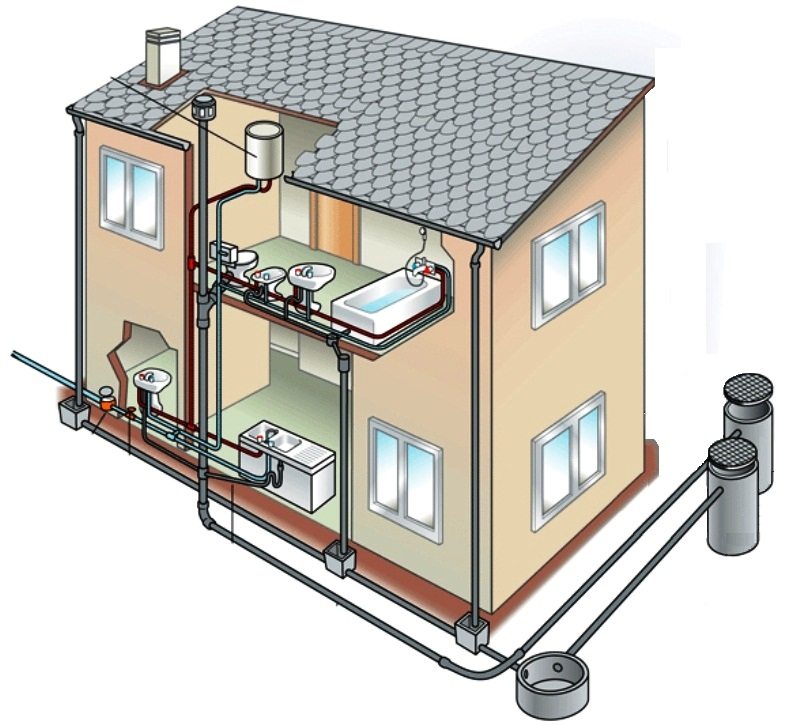

Many owners of private real estate sooner or later begin to think about arranging communication and other life support systems. At the same time, sewer wells play an important role, because this is an integral part of any sewage disposal system. From their features will depend on how often you have to carry out cleaning, what problems may arise during the maintenance period and much more. At first glance, it seems that there is nothing difficult to understand in the construction of sewer wells. However, this is not the case. What are these elements?

Sewer wells should be present at each site, and therefore it will be useful to study how they are arranged and a number of features inherent in them.

General information

In any drainage system, at least one well or reservoir must be present. Many owners of suburban real estate prefer autonomous sewers. But it is worth considering that this is a rather complex model project of engineering thought, requiring certain knowledge and skills.

A key element of such a system is sewer wells, which can have any shape - round, square, rectangular. They can be made of different materials, whether it is concrete rings, bricks or finished plastic containers.

From a structural point of view, the device of sewer wells is represented by several components:

- base;

- a tray;

- a working chamber;

- neck;

- hatch.

Now it’s worth getting acquainted with the main types of sewer wells, which are often installed by many private sector owners.

Varieties of wells

Similar structures are divided into several types:

- Lookouts.

- Rotary.

- Overflow.

- Overflowing.

- Cumulative.

- Filtrational.

In addition, each of these wells fulfills its duties. If a simple sewage system is located on the site, then only one storage well is enough. At the same time, with a more complex scheme, it will be necessary to study the device and the installation features of each of all the types listed.

Viewing structure

By the design of a viewing sewer well, one should understand a shaft located above the main outlet line. Such facilities allow visual inspection of sewer pipes and, if necessary, carry out repair work or mechanical cleaning, flushing during operation.

Such shafts are located on a straight line of the drainage system at a certain distance from each other. Usually it is 30 m, but the distance may vary depending on the diameter of the pipes. At the same time, the definition of “viewing well” may include mines that are installed on bends or on the intersection of communications.

Rotary shafts

They are installed in those places where sharp turns of the channel are necessary. That is more than 90 °. Mostly, the presence of such structures is due to the fact that it is in these areas that the system is actively clogged. In addition, this design can be used as a viewing shaft, which makes it easy to clean a specific section of the pipe.

In the course of arranging a well system, it is quite often necessary to place a septic tank or reservoir in a distance from several sources of sewage. And this inevitably leads to the appearance of turns.

Overflow facilities

Such reservoirs are relevant in the case of arranging a complex system on a site with a slope. The installation of a differential sewage well is necessary in the following cases:

- when the depth of the ditch under the branch line decreases;

- there is a need to bypass other underground utilities or pipes;

- prevent high speed water movement.

If the effluents enter the well at high speed, the insulation or the structure itself may suffer as a result of leaching or under the influence of shock. In turn, this design is also divided into several subspecies:

- An ordinary mine, in which the water supply is located in the upper part, while the drain is in the lower part.

- A design having a baffle plate that slows down the flow rate.

- Short channels with a large degree of slope, on the contrary, to increase the flow rate.

- A mine that includes multi-stage drops.

In this regard, the deceleration of the flow rate is the main purpose of the differential shaft.

Overflow type wells

Devices of an overflow sewerage well are differently called overflow septic tanks. In fact, these are several storage tanks that are connected to each other via overflow pipes in the upper part.

The main purpose of such a structure is to collect sewage. In this case, insoluble contaminants accumulate at the bottom of the first tank. After that, the purified liquid is sent through inclined pipes to the next drive.

The system provides for the separation of solid and liquid phases of sewage. And the main feature of overflow wells is that their operation does not require auxiliary equipment and electricity.

Cumulative type

Such facilities, in fact, are containers for collecting and storing discharged water. Subsequently, it is pumped out by pumps, or special machine-suction trucks can be involved in the work.

Among other types and devices of sewer wells, this option is more preferable for private suburban areas. In particular, this is an advantageous solution when the central system is too far away or absent. Based on the volume, such structures can be made of different materials. But most often these are reinforced concrete rings, large plastic containers, or it can just be a monolithic concrete structure.

If the amount of wastewater is small, then this option with the installation of a container made of plastic is fully justified. The cost of the tank is not very high, and its installation can be done independently. In addition, there is no need to involve a professional team together with specialized equipment. It is enough to enlist the support of acquaintances, which will greatly simplify the task, since it will be difficult to cope alone.

Filtrational variety

Another type and arrangement of a sewer well that is worthy of attention. Filtration facilities or mines can be either open or closed. At the same time, both options are intended for the separation of wastewater, and they also allow you to separate large debris and heavy substances from the water itself.

An open shaft is a structure for the manufacture of which perforated concrete blocks are used. The liquid, meanwhile, goes into the ground through special holes. As for heavy substances, they remain in a similar structure and then are scrapped with the help of special equipment and are disposed of or buried.

List of rules and requirements

The planning and construction of sewage systems is regulated by special rules and regulations, as well as regulatory acts (SNiP). In this case, the most important point is the distance between the sewer wells. The dimensions of the pipeline depend on this parameter.

In other words, if the pipe has a diameter equal to 150 mm, then the step between the wells should be 35 meters. With a diameter of 200 mm, the pitch is already, respectively, another - 50 meters. Similar requirements are given in another, no less important document - a technological map for the installation of sewer wells.

In fact, the requirements of SNiP for the arrangement of sewer wells are a kind of instruction that spells out the rules for installing sewage pipelines. Also in such a document contains technical requirements that apply to various designs of wells, taking into account sanitary and technical safety standards.

The fundamental requirements of SNiP can be considered:

- Wells should be located away from sources of drinking water and other water supply systems.

- Mines should be at a certain distance from residential buildings and neighboring sites.

- The volume of the well should be regulated by the number of people living, as well as the average volume of wastewater for a certain period of time.

- The depth of the pit for installing the tank should be within 2.5 meters, nothing more. As for its diameter, it should exceed the dimensions of the structure by no more than 0.5 meters.

- If a high level of ground water lies on the site, then according to Construction Norms and Regulations the sewer well device should include the arrangement of waterproofing.

- The bottom of the pit should be covered with a sand cushion at least 100 mm thick.

- There must be a gap of 600 mm between the bottom of the tank and the bottom of the pipe.

Installation of a sewer well made of concrete is regulated by GOST. While the installation of communications made of plastic and polymers is responsible for sending to TU. Concrete or stone structures can be prefabricated or monolithic. Filtering structures are erected mainly from rubble stone. As for polymeric materials, with regard to sewage systems, the use of polypropylene, polyvinyl chloride, and dense polyethylene is permissible.

Modern communications, which are mounted in urban construction or the private sector, can combine elements from different materials. Such decisions do not contradict building regulations.

Features of different types of wells

In accordance with the same norms and rules (SNiP), the sewer well device must take into account the installation features of each type, based on their purpose and the materials used. The filtering well is intended for purification of drains from harmful impurities. For this, the bottom of the collector must be covered with crushed stone, and the layer thickness is at least 1000 mm. After that, only its perimeter should be poured with concrete mortar. This will avoid the destruction of the base and the withdrawal of water through the center of the circle, where, in fact, drainage and cleaning are performed.

A manhole is usually constructed from a 460 mm diameter pipe. This size allows you to clean the tank from the hose. If there is a need to descend into the internal cavity of the structure, then the diameter of the pipe should be at least 925 mm. If the inspection manifold is being built on a site where there is no pavement, a blind area is required for drainage. With high-quality pavement, installation can be carried out 70 mm above the surface of the soil.

According to SNiP, the device of the sewer well of the accumulative type should be equipped in the lowland of the site to facilitate the flow of water into the tank. The design is located at a depth of 3000 to 6500 mm, and the number of rings is not more than 7. Special recesses are made at the bottom of the tank, which are then filled with sand or gravel. Water from such a structure is quite suitable for domestic needs.

Plastic wells - a modern and profitable solution

In relation to a private suburban area, plastic wells are most suitable for arranging a well system. This choice is due to the presence of certain design features, which are also advantages. In particular, we are talking about the following:

- Lower tray interchangeability.

- The connection of the nozzles with the well structure is carried out by a seamless method. Due to this, a high degree of tightness is achieved. In this regard, the front of work on sealing joints is significantly reduced.

- The construction of a sewer well in a private house made of plastic is more than justified, since the advantages of such structures in comparison with metal, concrete and ceramic counterparts are quite obvious. They are most often used during the creation of urban communications.

- Manufacturers of plastic wells create all the necessary and favorable conditions. Pipes are created in such a way that the time for connecting pipes is noticeably reduced. In addition, such structures already initially have rubber seals in the places where the pipes are connected. When using waterproofing materials, a reliable connection is provided that can last several decades without leakage.

- The design of the well itself is made seamless, due to which its tightness is increased, and the cost of installation work is also reduced. In fact, this is a large-sized pipe with a bottom, which has one or more inlet pipes.

- Well, actually, without the device of the manhole of the sewer well, precipitation or foreign objects would get inside. In this regard, the lid is also sealed.

In other words, the plastic construction of the well is an economical and environmentally friendly option during the installation of the sewer system. With the help of this product, it is possible to control and maintain sewer networks of domestic wastewater.

Features of choosing a plastic well

We have already familiarized ourselves with the features of plastic wells (they are also advantages), now it is necessary to consider the important main factors that will make the right choice of the right design.

In particular, it is necessary to pay attention to some parameters.

- Diameter and height - the construction of the well can be deep or wide. In this case, it is worth considering the features of the sewer system itself, including the location of the future structure in accordance with the rules for the construction of sewer wells.

- Shape - usually in most wells it is cylindrical, but there may be other options. At the same time, the only type that is better not to use for the storage structure is square tanks. In such wells there are ribs, which is due to the feature. In such places, sediment is deposited, and removing it is quite problematic, if not completely impossible.

- Displacement - such an indicator also deserves attention. Taking into account the average indicator of the amount of sewage during the day, as well as the volume of storage capacity, you can determine how often you will have to pump them out with a sewage machine.

- Type of surface - smooth or corrugated. Both of them have their advantages and disadvantages. As an example, a corrugated type of surface has greater elasticity and is able to withstand a lot of pressure than the usual look. At the same time, dirt often accumulates in existing small depressions, and it is very difficult to remove it from there.

- Wall thickness - this parameter is important in the construction of a concrete tray in a sewer well. It can vary over a fairly wide range. But the thicker the wall of the well, the higher its strength characteristics. But there is a flip side to the coin - an increase in thickness inevitably leads to an increase in the mass and cost of the structure.

In addition, you can look at exactly what type of plastic is used in the production of a particular well. This moment is not so significant, however certain operational properties depend on it.

Reinforced Concrete Wells

Such facilities are in high demand among most utilities involved in the maintenance and construction of underground pipelines. In addition, they find application in the arrangement of drainage and storm sewer systems, collectors. Is it worth mentioning that this is an ideal option for a home sewer system in your private suburban area? In addition, this material has no analogues in its field.

Due to its high operational qualities, the technology for constructing a sewer well made of concrete rings is suitable for implementation in any climatic zone. The wide scope of reinforced concrete rings, including their enormous popularity, is due to a rather impressive list of advantages:

- Affordable price.

- Installation can be carried out in a short period of time.

- Waterproofing is light.

- High strength characteristics.

- Durability of construction.

- .

, , . .

. b. , , , :

, , .

. .

After that, you can proceed directly to the arrangement of the well. To do this, it is worth arming with the following algorithm, which is also divided into several important stages.

Step 1. It is necessary to remove the soil from the inner contour so that the structure can be aligned horizontally. In order to avoid errors, it is worth connecting a level to this process.

Step 2. Carry out the installation of the first ring, after which it is necessary to make holes in its walls that will be designed for pipes. At the same time, they should be inserted into the ring itself at a distance of no more than 100 mm. Around the circumference of the pipes, the hole must be sealed with a solution.

Step 3. At this stage, the tray is installed in the sewer well (SNiPom is allowed and even recommended). Otherwise, it is called a gutter, which will be located from the inlet of the pipe to the outlet. Its cross section should correspond to the diameter of the pipes. The gutter can be made from part of the sewer pipe.

Step 4. Now another ring is installed, and it is necessary to make sure that the locks on its inner side are at the same level. In the same order, all other reinforced concrete elements are mounted.

Step 5. After installing the last ring, the bottom of the structure is concreted, and the joints of the rings are sealed with a sand-cement mixture. The arrangement of the filtering septic tank at this stage looks a little different - instead of filling the bottom with concrete mortar, it is covered with crushed stone or crushed brick. The thickness of such a layer should be at least 500 mm.

Step 6. Now the whole structure is covered with a concrete slab with a hatch. Or, as an option, install the frame with the hole and pour it with concrete mixture.

Step 7. Upon completion of the installation of the structure, the technology for constructing sewer wells provides for the laying of a pipeline. This is done at a depth of 600-700 mm with a slope of 20 mm and a meter pitch.

Step 8. At this stage, the facility is tested throughout the day. This is done as follows - the collector is filled with water, and the ends of the pipes are closed with plugs.

Step 9. Upon completion of a successful test, the outer walls of the concrete tank are covered with earth and carefully packed.

Step 10. We can say that this is the final stage at which the concrete blind area around the neck. Its width is 1500 mm.

Sewer Tray

The trays in the design of the wells are made to perform important tasks. They serve to ensure control over the operability of the sewer network and connected facilities. In this case, this part can be formed before installing the first reinforced concrete ring, if this material was chosen for the construction of the well.

In accordance with SNiP, the arrangement of trays in sewer wells, as a rule, is made of concrete of the M-100 brand with the use of formwork and the subsequent mandatory reinforcement with a steel mesh. Usually it takes about 2-3 days to strengthen it, and after this time, you can proceed directly to the installation of the rings. Subsequently, it will be possible to finish the tray with plaster followed by ironing.

Preventive actions

The effective performance of the sewer system largely depends on the conditions of its operation, including prevention. This means pumping and cleaning all the elements, and this must be done regularly. The frequency of such procedures, in turn, is directly dependent on the type of structure, as well as the capacity of the tank.

If cleaning is carried out irregularly or is completely ignored, then after a while the accumulation of garbage in the sewer system will inevitably lead to the formation of a mash. Ultimately, because of this, an unpleasant odor may appear in the well.

Even if a drainage pump device is provided in the sewer well, this does not save him from regular cleaning, since sludge and other garbage are collected at the bottom. Usually this event should be held at least every 2 or 3 years.

And how, in fact, is this procedure carried out? There are several ways to do this:

- Special equipment for collecting sludge.

- Vacuum pumping.

- The hydrodynamic technique, in other words, is flushing with water, which is supplied under high pressure.

- The use of chemicals.

- The thermal method is practically the same as the hydrodynamic method, only in this case hot water is supplied.

To implement the first two methods, you need to contact the slave service.

The rest of the techniques can be easily performed independently. Upon completion of the well cleaning, manual processing is necessary. Only in this case can we talk about full and effective prevention.

Useful Tips

In the end, you can give some useful tips from people who can tell a lot about the construction of sewer wells.

Do not make the depth of the trench too large. In this case, it becomes necessary to add soil, and over time it has the property of subsidence. For this reason, the line can change the slope, which is undesirable.

To avoid damage to the pipeline, solid objects should not be placed under it during installation.

When choosing a site where a filtration or storage collector will be installed, it is necessary to provide an opportunity for the entrance of equipment with which it will be cleaned.

Despite the fact that the well, in fact, is a wet structure, it is necessary to ensure its tightness. This measure is due to the fact that it eliminates the penetration of wastewater into the environment. Waterproofing of sections connecting reinforced concrete rings can be performed using special waterproof compounds.

As we know, the device of a sewer well includes a stage of waterproofing. And while a layer of the corresponding material is formed, it is necessary to exclude any effect of low temperatures or mechanical stress on its surface for 72 hours. During this time, these areas must be regularly moistened with a conventional spray gun. In addition, it is recommended to cover the surface with a film, which will reduce moisture evaporation.