With the growing popularity of the installation in summer houses and household plots of easily assembled greenhouses in the market, the demand for arches for the greenhouse has increased. They are responsible for their durability and stability. This is a kind of "skeleton" of the greenhouse.

Mostly for the manufacture of arcs use plastic (or fiberglass), polypropylene, as well as metal. From what material the greenhouse is made of, its price, weight and maximum dimensions depend on it.

Another criterion by which the arcs for a greenhouse are distinguished is the method of assembly and installation of the structure. There are two large groups: prefabricated greenhouses and welded. The first can be assembled and disassembled several times. For this, detachable joints without fasteners or with the use of hardware products (bolts, nuts, screws, etc.) can be used. The disadvantage of this type of greenhouses is their small size and relatively low strength. Welded hotbeds are much stronger, however, after assembly, they are usually not subject to dismantling. Such designs are ideal for a personal plot and can be used year-round.

Consider each option in more detail. The case when the arches for the greenhouse are made of plastic is suitable for growing small plants, such as cucumbers or peppers. Such structures are usually covered with a film and used only in the warm season. To make such a greenhouse at home is not difficult. Polypropylene pipes, which can be found in any plumbing store, are perfect as a frame. A special “iron” is used for welding. Connections can be made collapsible, but this will affect the strength of the entire structure.

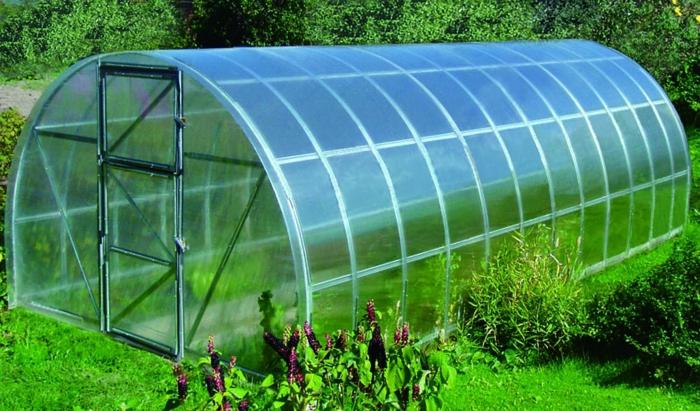

Metal arches for a greenhouse can also be both welded and prefabricated. However, unlike plastic ones, the second designs are more widespread, since they are faster to assemble and do not require welding equipment and special skills. Complete instructions for such greenhouses are provided, which greatly simplifies the work. As a covering material, polycarbonate or a plastic film are mainly used. The metal frame is much stronger than the plastic one, therefore it allows you to operate the greenhouse all year round, withstanding even the loads of snow cover in winter. Another indisputable advantage of metal arcs is the size of greenhouses. They can be made in human height and above, and also cover significant areas, depending on the design.

As for the independent manufacture of metal arcs, the situation here is more complicated than in the case of plastic. The material is much more expensive, and besides, the master must have special skills to perform such work, as well as use welding and other construction equipment. In addition, it is not difficult to buy arcs for a greenhouse today. The market is full of offers for the sale and manufacture of greenhouses for individual sizes. Ultimately, given all the costs, it is more profitable to purchase a finished construction with a metal frame than to try to do something similar on your own.