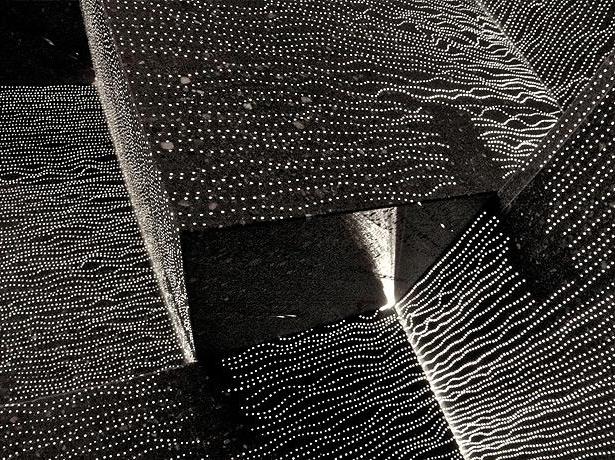

Almost any large-scale construction process involves the use of concrete mixtures. The solution acts as the basis in the formation of the foundation, walls are built from it, perform ceilings and implement other tasks. At the same time, the external ugliness of concrete does not bother anyone - it is skillfully masked by facing materials, so this nuance does not cause any special problems. Nevertheless, the Hungarian engineer Aron Loshontsi decided to add another quality to the list of characteristics of gray material - light transmission. Thus, the transparent Illumicon concrete appeared, which has many differences from traditional mixtures. This applies not only to the appearance, but also to the original structure, due to manufacturing technology.

Concrete composition

The basis is still a regular mortar made from a fine-grained cement mass. The technology itself revolutionized the concept of concrete only through the unusual combination of a familiar base mix and fiber-optic fiber. These are the threads that are used in telecommunication networks. It is through a combination of these components that transparent concrete forms. The composition of the main solution also involves the use of cement and water in accordance with technical requirements. As for the fibers, their parameters are selected according to special criteria.

As a rule, technologists do not recommend preparing masses in which the proportion of the content of optical elements exceeds 5%. This affects the strength and durability of the material. On the other hand, the very quality that determines the transparency depends on the percentage of fiberglass content. Most often, transparent concrete is produced using fibers whose thickness does not exceed 2 millimeters.

Manufacturing technology

Like the traditional method of creating concrete, in this case, work begins with the arrangement of formwork. Next, a solution is poured into it. It is important to note here that the concrete mix itself involves the inclusion of components with different characteristics. Fine-grained solutions exist, and in some cases it is appropriate to add crushed stone. It is the first option without the inclusion of fillers with a large fraction that allows you to get high-quality transparent concrete. The technology in terms of the use of fiber optic yarns provides for some kind of reinforcement. The key characteristic of the material, the ability to provide visibility, also depends on the accuracy of fiber laying. Another fundamental difference from the classical method of manufacturing concrete is the need to refine an already frozen mortar. Firstly, the formwork is freed, after which the monolith can be cut into separate blocks with the desired shape. Secondly, the formed lithracon is carefully polished.

Characteristics of clear concrete

Since the basis of the material is a completely familiar fine-grained mortar, its technical properties are in many respects similar to ordinary fine-grained concrete - for example, M250 grade. However, the presence of about 5% of a foreign element in the form of fiberglass still causes a number of differences. As for the density, it varies from 2100 to 2400 kg / m 3 . This indicator is superior to foam and aerated concrete analogues, but Litracon cannot compete with heavy compositions in terms of density. But transparent concrete shows good water resistance and frost resistance. Since the average compressive strength does not allow the use of light-conducting material as the basis for the construction of large construction projects, it is advisable to initially calculate the load on the material. If, nevertheless, there is a task of performing critical constructions from litracon, it is better to consider options for introducing additional plasticizers and additives that increase strength.

Fields of application

Nevertheless, the litracon is not intended for use as a building material, on which high power loads can be imposed. Moreover, pouring a foundation of fiberglass mortar does not make sense, since the light transmittance in this case will not be expressed in any way. The main direction of its use is the device of architectural compositions with decorative properties. Both in the creation of street design objects and in the decoration of interiors, transparent concrete has been successfully used. Its use is primarily due to aesthetic considerations, although the technical and physical qualities of the material are not discarded. One way or another, the basic set of components for litracone makes it similar to ordinary lightweight concrete, which can cope with the loads of small architectural structures.

Pros and cons of clear concrete

The main advantage of this material lies in the combination of seemingly disparate performance. This is a decorative effect and power potential, corresponding in its performance to lightweight concrete. As for the minuses, the average strength indicators by specialists are not even taken into account. A much more substantial high price. It is the inclusion of fiber optic filaments in transparent concrete that increases the cost of manufacturing the mortar.

How to make it yourself?

The highest quality designs of such concrete are produced in the factory and are implemented as ready-to-use design objects. But if you wish, you can make Litracon and yourself. The main difficulty will be the proper laying of fiberglass yarns. If the production of transparent concrete at specialized plants involves the operation of automated machines that form layers of fiberglass, then at home this work will have to be done manually. A shuttering structure is also formed, and then rows of light-transmitting threads are created in layers. In parallel, alternating filling of the layers with portions of the solution is performed. It is important to observe the concentration of fibers in the total mass, so that the concrete retains a sufficient margin of safety.

Conclusion

Quite often, improving the characteristics of the usual building material leads to a change in the direction of its use. Despite the similarity with classical mortars, transparent concrete is mainly used as a decorative object. To obtain a reliable power base, it is quite advisable to use conventional compositions, the aesthetic attractiveness of which does not matter during operation. Litrakon, on the contrary, is not of particular interest from the point of view of bearing abilities, but it is best disclosed in the form of an original design element.