Any production involves the use of instrumentation. They are necessary in everyday life: you must admit that it is difficult to do without the simplest measuring instruments, such as a ruler, tape measure, caliper, etc. during the repair. Let's talk about what measuring instruments and devices exist, what are their fundamental differences and where these or those types are applied.

General information and terms

A measuring device is a device with which the value of a physical quantity is obtained in a given range, determined by the scale of the device. In addition, such a tool allows you to translate values, making them more understandable to the operator.

The control device is used to control the process. For example, it can be some kind of sensor installed in a heating furnace, air conditioner, heating equipment and so on. Such a tool often determines product quality and properties. Currently, they produce a wide variety of measuring tools and instruments, among which there are both simple and complex. Some found their application in one industry, while others are used everywhere. In order to deal with this issue in more detail, it is necessary to classify this tool.

Analog and digital

Instrumentation and instruments are divided into analog and digital. The second type is more popular, since various quantities, for example, current strength or voltage, are converted into numbers and displayed on the screen. It is very convenient and the only way to achieve high accuracy of reading. However, it must be understood that any digital instrument includes an analog converter. The latter is a sensor that takes readings and sends data for conversion into a digital code.

Analog measuring and control instruments are simpler and more reliable, but at the same time less accurate. Moreover, they are mechanical and electronic. The latter are distinguished by the fact that they include amplifiers and value converters. They are preferable for a variety of reasons.

Different classification

Measuring instruments and devices are usually divided into groups depending on the method of providing information. So, there are recording and showing tools. The former are characterized in that they are capable of recording readings in memory. Often used recorders that print data on their own. The second group is intended exclusively for monitoring in real time, that is, during the reading, the operator should be near the device. Also, the measuring instrument is classified by the measurement method :

- direct action - the conversion of one or more quantities is carried out without comparison with the same value;

- comparative - a measuring tool designed to compare the measured value with the already known.

What are the instruments in the form of presentation of readings (analog and digital), we have already figured out. Measuring instruments and devices are also classified according to other parameters. For example, there are summing and integrating, stationary and shield, standardized and non-standardized devices.

Measuring bench tools

With such devices we meet most often. Here the accuracy of the work is important, and since a mechanical tool is used (for the most part), it is possible to achieve an error of 0.1 to 0.005 mm. Any unacceptable error leads to the need for regrinding or even replacement of the part or the entire assembly. That is why, when fitting the shaft under the sleeve, the fitter does not use rulers, but more accurate tools.

The most popular fitter equipment is a vernier caliper. But such a relatively accurate device does not guarantee a 100% result. That is why experienced locksmiths always make a large number of measurements, after which the

average value is selected

. If you want to get more accurate readings, then use a micrometer. It allows measurements up to hundredths of millimeters. However, many people think that this instrument is capable of measuring up to microns, which is not entirely true. And it is unlikely that when carrying out simple metalwork at home, such accuracy will be required.

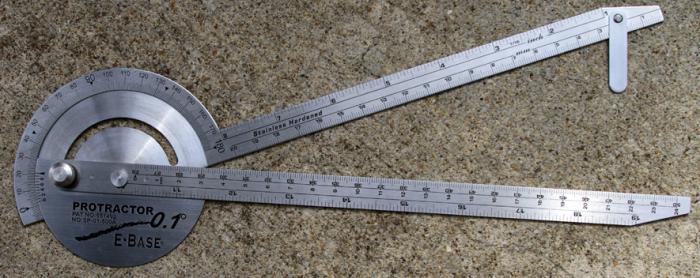

About goniometers and probes

One can not help but talk about such a popular and effective tool as a goniometer. From the name you can understand that it is used if you need to accurately measure the angles of the parts. The device consists of a half-disk with an outlined scale. It has a ruler with a mobile sector, on which the vernier scale is applied. To fix the mobile sector of the ruler on the half-disk, a locking screw is used. The measurement process itself is quite simple. First you need to attach the measured part with one face to the ruler. In this case, the ruler is shifted so that a uniform clearance is formed between the faces of the part and the rulers. After this, the sector is secured with a locking screw. First of all, the readings are taken from the main line, and then from the nonius.

Often, a probe is used to measure the clearance. It is an elementary set of plates fixed at one point. Each plate has its own thickness, which we know. By installing more or fewer plates, the clearance can be measured quite accurately. In principle, all of these measuring instruments are manual, but they are quite effective and hardly possible to replace them. Now let's move on.

A bit of history

It should be noted when considering measuring instruments: their types are very diverse. We have already studied the basic devices, and now I would like to talk about a little about other tools. For example, an acetometer is used to measure the strength of acetic acid. This device is able to determine the amount of free acetic acid in a solution, and was invented by Otto and used throughout the 19th and 20th centuries. The acetometer itself is similar to a thermometer and consists of a 30x15cm glass tube. There is also a special scale, which allows you to determine the required parameter. Nevertheless, today there are more advanced and accurate methods for determining the chemical composition of a liquid.

Barometers and ammeters

But practically all of us are familiar with these tools from school, college or university. For example, a barometer is used to measure atmospheric pressure. Today, liquid and mechanical barometers are used. The former can be called professional, as their design is somewhat more complicated, and the readings are more accurate. At weather stations, mercury barometers are used, since they are the most accurate and reliable. Mechanical options are good for their simplicity and reliability, but they are gradually being replaced by digital devices.

Instruments and measuring instruments such as ammeters are also familiar to everyone. They are needed to measure amperage. The scale of modern instruments gradients in different ways: microamps, kiloamps, milliamps, etc. Ammeters are always trying to connect in series: this is necessary to reduce the resistance, which will increase the accuracy of the readings.

Conclusion

So we talked with you about what control and measuring tools are. As you can see, everything is different from each other and have a completely different scope. Some are used in meteorology, others in mechanical engineering, and still others in the chemical industry. Nevertheless, they have one goal - to measure the readings, record them and control the quality. For this, it is advisable to use accurate measuring instruments. But this parameter also contributes to the fact that the device becomes more complicated, and the measurement process depends on more factors.