Many owners of building plots think about the question of how to build a house for permanent residence. There are a lot of options for solving this problem, the main thing is to choose the material that will provide comfortable living conditions. In addition, it should be convenient to work with, and it should not cost too much.

It is very important to lay the foundation of the walls of the product, which will differ in long service life, and will also have the ability to retain heat. For example, houses made of timber, the price of which is quite reasonable, just have such characteristics. A big plus will be if the walls after the construction will not need decoration.

Building walls made of wood

Man builds wooden houses, perhaps, throughout the entire period of his existence. But even today this material has not lost its appeal in terms of durability and thermal insulation qualities. Walls made of wood have the ability to breathe, such buildings look very attractive and do not look the same in comparison with other buildings.

A wooden house has many advantages. First of all, the building will not have significant weight, which indicates the opportunity to save money by abandoning the foundation of a deep foundation. Wooden houses are distinguished by the fact that they are based on natural material that is environmentally friendly and does not harm health. You can start building such housing at any time of the year, and work will be completed in a short time, which is especially noticeable when compared with the duration of the process of building a house from any other material. You can assemble the log house yourself by ordering material from a professional company. Logs ready for assembly will be brought to the construction site.

The cost of a wooden house

You can call into such a house immediately after construction, and it is recommended not to finish the work during the first years of shrinkage. Many do not do this at all during the period of operation of the house, since the walls made of wood look very attractive inside and out. Houses made of timber, the price of which varies depending on the area, can be ordered from the developer. So, a house with a usable area of 63 m2 costs 385,000 rubles.

Brick Walling

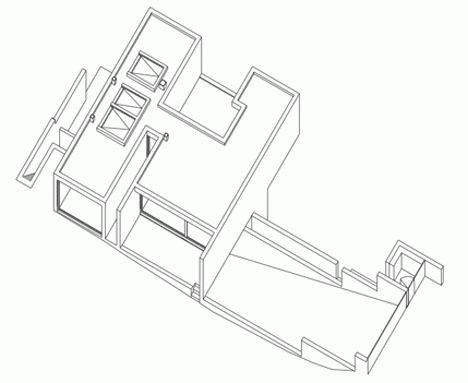

Despite the fact that wood is such an attractive material, brick is most common for the walls of a house today. Drawings of brick houses, which are presented in the article, must be made before the start of construction. Such buildings turn out to be durable, and there may be a ton of architectural solutions. Such houses do not cope well with the retention of heat in the interior space of the premises, however, during the construction process, you can apply some masonry techniques that will increase the thermal insulation characteristics of the walls. For example, it can be a well masonry, which involves the formation of a double wall, while a heater is poured into the free space between the walls.

Foundation for a brick house

The construction of brick houses involves the construction of a deep foundation, which will make the work more costly. But in this case, one can not do without the right foundation, because the construction will be very difficult. The process of building such a house takes a long time, because you will have to use mortar, as well as concrete, which requires a period of about a month to gain strength. The cost of the entire building will be more expensive compared to those where other products are used.

Creating walls from reinforced concrete panels

Many, wondering about what to build a house for permanent residence from, decide to use reinforced concrete panels. At the same time, there are some advantages, among them we can single out the opportunity to complete the construction in a short time, which in most cases is limited to two weeks. As soon as the construction of the walls is completed, it is immediately possible to begin external finishing work, which also attracts consumers.

Sandwich Panel Walls

To create their own private homes, not many today use sandwich panels, but in vain. These products are a pair of wooden boards, which are sometimes replaced with plywood or boards. In tandem with panels, a wooden frame is used, which acts as the basis, while a heat insulator is covered in the space between the walls. Such sandwich panels are produced in the factory, where typical designs are used. This indicates that the buildings on their basis are monotonous, but very warm. In addition, it is easy to build residential buildings using this technology, because the dimensions are calculated to a millimeter. And you can do the work without involving qualified craftsmen. It is permissible to start wall decoration after completion of the construction work.

You can not be afraid that the walls built by this method will be affected by water or insects, because the material undergoes special chemical processing at the plant. This, among other things, allows you to get walls that are protected from fire. The service life of such houses is equivalent to that of wooden houses.

Lightweight concrete walling

If you still have not decided what to build a house for permanent residence from, then some experts advise using lightweight concrete blocks. They can be in standard sizes or made to order. You can choose those products that are more suitable for you according to their quality characteristics, the last of which are determined by the placeholder. So, Portland cement is certainly used as the basis, while slag or expanded clay can act as an additive. As a result, slag concrete or expanded clay concrete is obtained. Such material can be cast not only into molds for producing blocks, but also into formwork, which in the latter case allows you to create a monolithic slab. The houses from the blocks are inexpensive and of high quality.

At the heart of the walls can be another lightweight concrete, which is enclosed in a foam block. This material is affordable, which reduces the cost of construction by 3 times. Such concrete is convenient to use in work, since it has a small weight. In addition, such products have a cellular structure, which provides better heat resistance. If necessary, the block can be cut quite easily.

Gas block construction

Thinking about what to build a house for permanent residence from, you can choose aerated concrete. The complexity of using it is much less than in the case of bricks. The houses are light and warm. Much less is spent on heating resources, which saves money . You can save already at the construction stage, because one gas block in volume is 16 bricks. Moreover, its weight is negligible, which allows you to complete the work in a much shorter time. In addition, aerated concrete products do not exert impressive pressure on the base of the house, this indicates that there is no need to make the foundation buried.

Residential houses made of this material have a heat capacity, if only to avoid the bridges of cold during installation. This can be achieved through the use of special glue, which allows you to get thin seams. If you use a traditional solution, the seam thickness will be increased to 22 mm, and you will save only at the construction stage, which cannot be said about the period of operation of the house, because if there are walls with cold bridges, they will have to be insulated, and the rooms themselves will be heated more.

Characteristics of aerated concrete

Houses from blocks should be built with extreme caution, because the more impressive the heat-saving characteristics of the product, the more pores the material has, and they make it not as strong as we would like. Aerated concrete can be finished inside and out as you wish, this will allow you to get a building that has unique aesthetic and architectural features.

Choosing blocks for the house? Which is better to buy? Experts recommend choosing those products that have perfect geometric shapes, this will facilitate the construction process and make it faster. In addition, due to the unevenness of the blocks there will be no overspending of the adhesive composition. Quite often, owners of future houses resort to the decision to independently manufacture lightweight concrete, this is only advisable if it is possible to rent appropriate equipment inexpensively, because in the absence of the right tools, lightweight concrete will be too expensive.

The construction of brick houses today is very common, but consumers often tilt their choice towards other materials that were described above. If you intend to start building your home, you should consider the characteristics and features of working with other materials.