In every modern apartment in the kitchen or in the bathroom you can see an automatic washing machine. Currently, manufacturers offer a huge variety of brands and models of washing units that work on the same principle, but are most often equipped with technological units of their own production.

Experienced craftsmen call the heart of the washing machine a drain pump, which ensures the normal functioning of the entire unit. Therefore, often in the event of malfunctions of the home assistant, you need to know the types, classification and characteristics of the pumps. Knowing the operating rules and the care features of the washing machine pump will significantly extend the trouble-free service life of the entire unit.

Appointment

The washing machine pump performs one of the main functions in the correct and uninterrupted operation of the unit. The main role of using a drain pump is to remove dirty water from the tank of the washing machine. The entire washing cycle is completely dependent on how this unit works, because the pump is involved in all washing modes (washing, rinsing, spinning and drying).

The need for periodic draining and collection of water imposes a large load on the drain pump, therefore, for the trouble-free operation of the entire mechanism, the basic rules for operating the washing machine must be observed.

Drain pump device

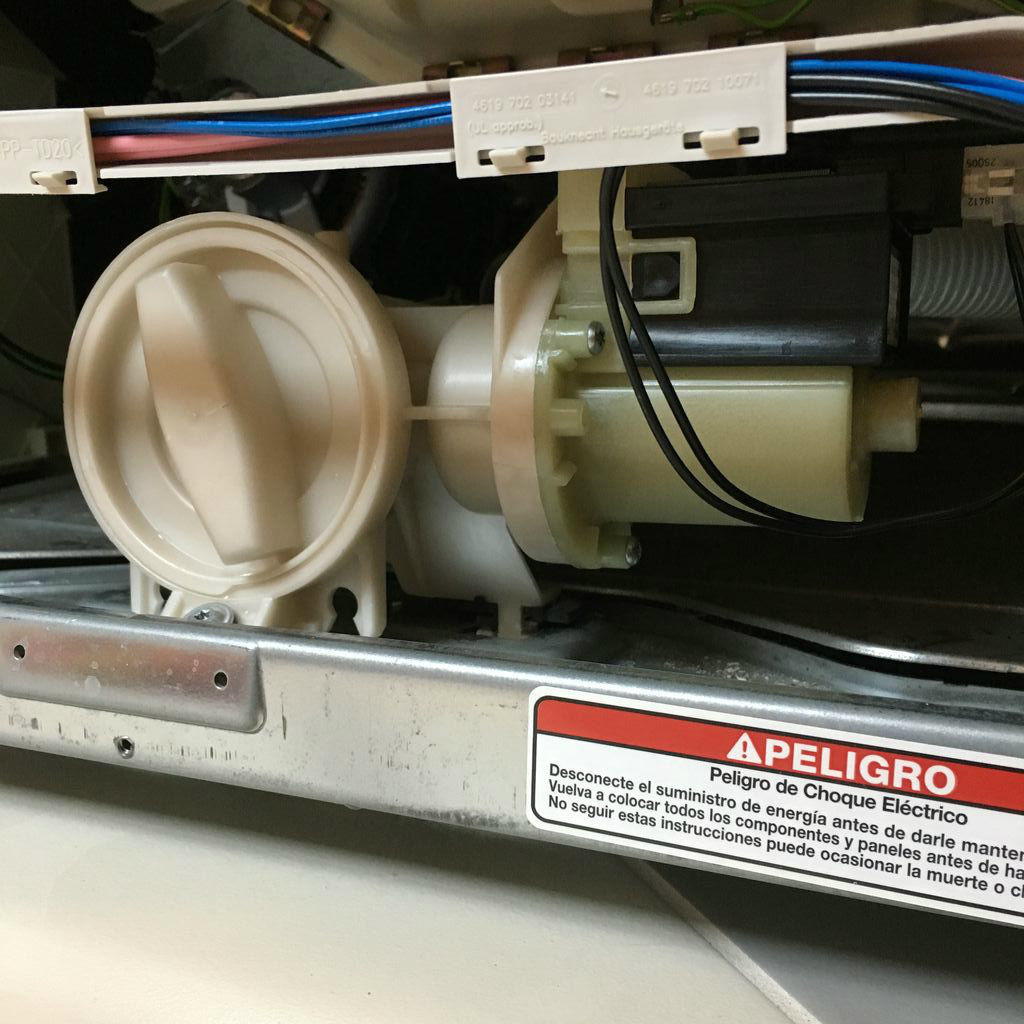

Structurally, the drain pump (pomp) for the washing machine is an electric motor of small power, the impeller is mounted on its shaft, which contributes to the pumping of used water.

The main components of the pump are:

- medium power electric motor;

- motor shaft;

- impeller;

- sealed enclosure in the form of a snail with two nozzles.

One branch pipe serves to remove water from the tank of the washing machine, and the second is connected by a drain hose to the sewer.

Technical characteristics of the drain pump

The main characteristics of various models of drainage pumps of washing machines may vary depending on the power of the units.

The standard technical indicators are:

- productivity is about 20 liters of water per minute;

- rated value of electric motor power is about 30 W;

- the motor winding has a resistance of about 160 ohms;

- the ability to raise water by a maximum of one meter;

- water temperature should not be higher than 90 ° .

To protect the winding of the electric motor from overloads, a thermal relay is installed , which is designed to operate at a coil temperature of 150 ° C.

Types of pumps

Currently, there are drain pumps for washing machines of two types:

1. The circulation pump is mainly used in premium washing units. Such a pump delivers the washing liquid directly to the place of washing and produces a forced circulation of water in the process of doing the work. Typically, a circulation pump is installed in conjunction with a simple drain pump that pumps water. Such a constructive solution makes it possible to wash dirty laundry much more efficiently.

2. In cheaper models, an ordinary drain pump is used, which only removes liquid from the tank into the sewer system.

Also, drain pumps in various models of washing machines can differ in the shape of the cochlea and the type of filter that is located inside the housing.

The main malfunctions of the drain pump

During the washing process, the pump of the washing machine is turned on several times, depending on the mode selected. Therefore, a large load on the parts of this important unit is the main reason for the failure of the pump.

Typical malfunctions of the drain pump are:

- frequent activation of thermal protection of the motor winding;

- impeller clogging, which leads to its jamming;

- broken impeller blades with foreign objects;

- premature wear of bushings located on the motor shaft;

- the impeller of the pump scrolls or falls off the shaft of the electric motor;

- Short circuit or open coil of the motor winding.

All these failures lead to the repair of the washing machine pump. Typically, repairs can be carried out after minor malfunctions such as impeller clogging, as well as slight damage to the blades. Other failures lead to a complete replacement of the pump of the washing machine.

Replacing the pump through the bottom of the washing machine

The drain pump is located in the lower part of the unit, under the tank. Only now access to it can be made through the bottom of the washing machine or after removing the front panel.

The replacement of the pump for the Samsung washing machine is done through the bottom of the unit.

Instructions for dismantling the drain pump are as follows:

- Be sure to unplug the washing machine.

- Shut off the water supply before disassembling.

- Gently lay the washing machine on its side. In this case, the pump must be on top of the unit.

- Release the bottom of the machine from the lower access panel. For this purpose, it is necessary to remove the fastening latches.

- If there is a plastic pump guard, this element must also be removed.

- Near the pump valve, you will see the screws that secure the assembly, which must be unscrewed.

- Gently pull the pump towards you.

- Then disconnect the pump power wires.

- Above the prepared container, in order not to spill any remaining water, loosen the hose clamps.

- If the pump is with a snail, then it is necessary to disconnect it. In the future, if there are no complaints about this element, then after cleaning the snail can be left.

Installing a new or refurbished pump is performed in the reverse order.

A similar method is used to disassemble the pump in washing machines Indesit, LG, Beko and some other models.

Removing the pump through the front panel

The replacement of the pump of the Bosch, Siemens, and some other brands of washing machines is done after removing the front panel of the unit, since the bottom of such machines is closed.

Dismantling the drain pump is as follows:

- First of all, it is necessary to remove the top cover of the unit. To do this, unscrew the fastening screws on the back of the machine, and then push the cover away from you from the front panel.

- The next step is to dismantle the control panel. For this purpose, the tray for washing powder is removed and the screws that secure the panel are loosened. After removing the screws, the panel is neatly laid on top of the unit so as not to damage the connecting wires.

- There is a drain valve under the plastic cover plate, which must be removed carefully above the container in order to drain the remaining water.

- Then it is necessary to remove a sealing cuff from a loading hatch.

- Thus, having dismantled the front panel, we get access to the pump.

- Having unscrewed the fastening screws of the pump and the front wall, you can proceed to dismantle the pump.

- After loosening the clamps on the pump nozzles, remove the connecting hoses.

After performing all these operations, we inspect the pump and the impeller. In case of minor breakdowns, we clean the pump parts from contamination. Install a new drain pump in the reverse order.

In top-loading washing machines, the pump is disassembled through the rear wall.

Pump Operation Rules

In order for any complex technical unit to develop its service life, you need to monitor its condition and fulfill some additional recommendations of the washing machine manufacturer:

- Check clothing pockets before washing to prevent small items from falling into the rotating parts of the unit.

- Use only special detergent for automatic machines, which include scale additives.

- It is advisable to install a filter on the water supply system so that small particles of rust from the pipes do not get inside the machine.

- It is better to soak very dirty laundry before washing.

Remember that if there are signs of malfunction of the washing machine, you must immediately begin to identify and eliminate the breakdown. It is easier to replace a failed drain pump than to change the entire unit in the future.