How to choose the right equipment for the organization of autonomous water supply? Along with the arrangement of the source of water intake (well, well), special attention should be paid to the method of raising the liquid from them to the surface. To solve this problem, submersible centrifugal pumps are most often installed.

Destination

Autonomous water supply consists of several elements: a source of drinking water, a piping system and pressure generating mechanisms for transporting liquid. Their proper design and interaction with each other is the key to optimal performance.

Pumping equipment is the main part, which should solve the following tasks:

- The rise of drinking water from an underground source to its distribution system.

- Providing the required pressure and volume.

- Uninterrupted operation (in accordance with operating conditions).

- Maximum ease of management and process automation.

One of the optimal solutions that satisfy the above conditions will be the installation of centrifugal pumps. Along with a simple and reliable design, they have good performance properties. Their main area of application is raising water from wells and wells. Depending on the depth, submersible centrifugal pumps of various capacities are installed. For artesian wells, this figure can reach 50 m. Wells in most cases have a depth of up to 7 m.

Operating principle

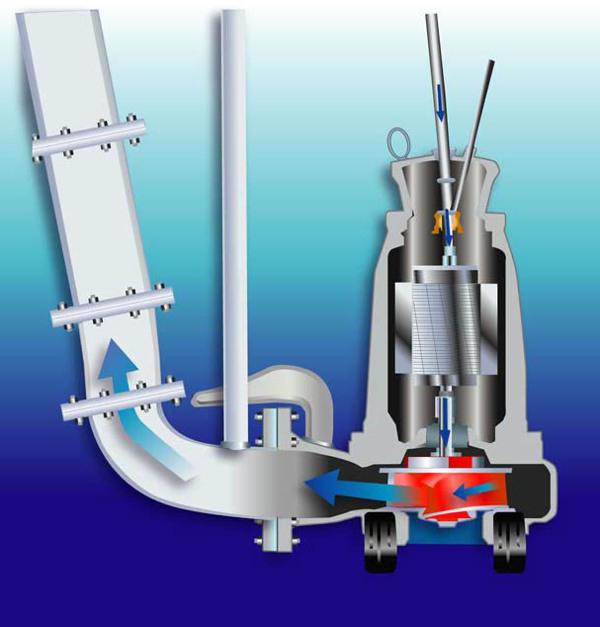

The basis for the correct selection and operation is a work scheme that distinguishes submersible centrifugal pumps from other devices of this purpose. Their design meets the operating conditions - being in a liquid medium, the housing must not be corroded. Since an electric motor is used as a power unit, its full waterproofing is mandatory in order to avoid breakdowns and malfunctions. Consider a submersible centrifugal pump device. A typical pump consists of the following elements:

- An electric motor is a sealed part of a pump in which a power unit is installed. Using the shaft, the rotational energy is transferred to the next node.

- Blade compartment - located at the bottom of the device. Designed to create pressure, due to which water rises.

- Pipeline - a transport unit for moving fluid to a consumer point - a home or watering system.

The pump is made of non-corrosive materials - high quality polymers or stainless steel. In the lower part of the housing are receiving holes that act as a filter. Large debris does not enter the pump. During the rotation of the blades under the action of centrifugal force, water masses move along the receiving chamber of the device. At the same time, they serve as an engine cooler, preventing it from overheating. For timely start (stop), float water level sensors are connected to the pump control unit. In addition to them, external control elements can be connected to the system - a pressure switch in the water supply of the house or direct connection (shutdown).

Kinds

Depending on the technical specifications, submersible centrifugal pumps may vary slightly in design. When choosing the optimal model, one should take into account the composition and degree of water pollution, as well as its depth. The last factor will directly affect the power of the pump.

The design of household models is relatively simple: the engine, together with the impeller, generates sufficient water pressure during operation. They are simple, reliable, have small overall dimensions. But if the horizon of drinking water is deep enough, complex types of construction should be established.

To increase this parameter, centrifugal submersible pumps for water are equipped with a more powerful engine, or a vertical pulley with several impellers. Due to this, they create an increased pressure of water to raise it to the surface.

Similar designs are also used for pumping oil. They have good performance, and most importantly - reliable.

Specifications

A standard household submersible centrifugal pump is selected based on its technical characteristics. In this case, you should pay attention to the power indicator. It is a determining factor when choosing a specific device model. In addition to this, you must know the following device parameters:

- The volume of the pumped-over liquid - l / min.

- The height of the water column. Determines the maximum depth of the well (well) and the horizontal length of the pipeline.

- Additional equipment - water level sensors and emergency shutdown.

The case of most devices is made of stainless steel. In low-power models, designed for a small height of water supply, it can be made of polymeric materials.

terms of Use

Modern submersible centrifugal pumps must operate under conditions that are clearly specified in the instructions. Not only the quality of the device, but also its durability will depend on this. The main operational characteristics include the composition and temperature of the water, its degree of contamination. Special attention should also be paid to stabilizing the applied voltage.

Submersible centrifugal pumps for wells are often installed in household plots, where current surges are a common occurrence. The electric motor does not have effective protection against such changes. Therefore, it is recommended to connect the device through the stabilization unit.

Installation

The basic installation rules are described in detail in the operating instructions. If you need to install a centrifugal submersible pump for a well, you should consider the system of its fixation. There is a special fastener on the pump casing. It is required to install a submersible cable.

The material of its manufacture must meet the following requirements:

- Do not corrode.

- The tensile load must be at least 5 times the weight of the device.

Never lower the device with the power cable. The main load should fall on the mounting cable. It is mounted on the surface: either to the transverse beam on the neck of the well, or on the outer protective walls of the well.

Service

The instructions also indicate the estimated duration of the preventive work. Basically, they consist in checking the tightness of the housing, replacing the rubber seals on the engine stem and cleaning the connection contacts. In the event of an unforeseen breakdown, contact the representatives of the manufacturer or a specialized repair shop.

It should also be borne in mind that submersible centrifugal pumps can be optionally equipped with filters for pre-treatment of water. They are installed on the inlet of the device and replaced as they become dirty.

Selection tips

Before purchasing, you must clearly know the operating conditions under which the centrifugal submersible pump for the well will work optimally. To do this, it is recommended to adhere to the following recommendations:

- Water consumption. The water feed rate must comply with the design standards.

- The height of the water column. When calculating it, not only the depth of the well (s) is taken into account, but also horizontal sections. For them, a reduction factor of 0.1 is applied. If the well depth is 7 m, and the horizontal pipeline has a length of 12 m, then the minimum height of the water column of the pump should be: 7 + 12 x 0.1 = 8.2 m.

- The presence of water level sensors in the kit.

- Warranty on equipment, remoteness of the service center of the equipment manufacturer.

Given these indicators, you can choose the optimal model of the pumping station, which will provide the proper amount of water. In addition, they can perform the functions of draining flooded cellars and cellars. The main thing is to take into account the composition of the liquid and the permissible norms of its contamination for a particular pump model.

Due to this, they create an increased pressure of water to raise it to the surface.