Low tides for the basement base - These are plastic or metal moisture protection strips installed at the junction of the base and the wall. Their purpose is to protect the foundation from atmospheric influences and precipitation flowing down from the roof and upper floors, thereby preventing its premature destruction and deformation.

Why do we need tides for the basement base

From whatever material the house is built, it still requires reliable protection from atmospheric influences, especially from moisture (rain and snow). And a very important element of protection is the ebb tide, which is able to extend the shelf life of the foundation and, accordingly, the entire room. Melt and rain water through microcracks and pores penetrates the foundation and walls of the house, which can lead to mold and dampness, loss of thermal insulation properties of walls and cause rapid wear and aging of the entire structure. Low tides for the basement of the foundation make it possible to keep it in a dry state, creating conditions for their maximum safety and ensuring a comfortable microclimate in the house. But, in addition to the protective function, they also have aesthetic significance, since without this element the building would have looked unfinished, and the basement would have been sloppy. In their appearance, the tides resemble an inclined shelf along which moisture flows down.

Ebb materials

Today's construction market offers castings for foundations made of different sheet materials: aluminum, copper, galvanized steel, including polymer coated, plastic, etc. Products created by the factory method are available in a variety of colors, which allows a significant as much as possible to improve the aesthetic appearance of the facade of the house. As a rule, shades of tone are chosen to match the basement of the basement or walls, however, you can choose contrasting or metallic elements that will give the building a special charm.

Products can be purchased ready-made with standard sizes, or made to order, which will be the best option. In this case, the design of the building itself and its characteristics are taken into account.

Base ebbs can be of very different widths, which depends on the size of the protrusion and the width of the opening.

Preparatory work

Installation of ebbs, as a rule, does not cause any special difficulties, therefore, this work can be done independently if desired. So that this does not take a lot of time, you should initially determine the correct dimensions of the depth and width of the surface.

Before you begin mounting the tides to the wall, you must check its integrity. If cracks, chips or voids are found, they must be sealed with silicone sealant, putty or plastered. All other work is carried out only after complete drying of the composition.

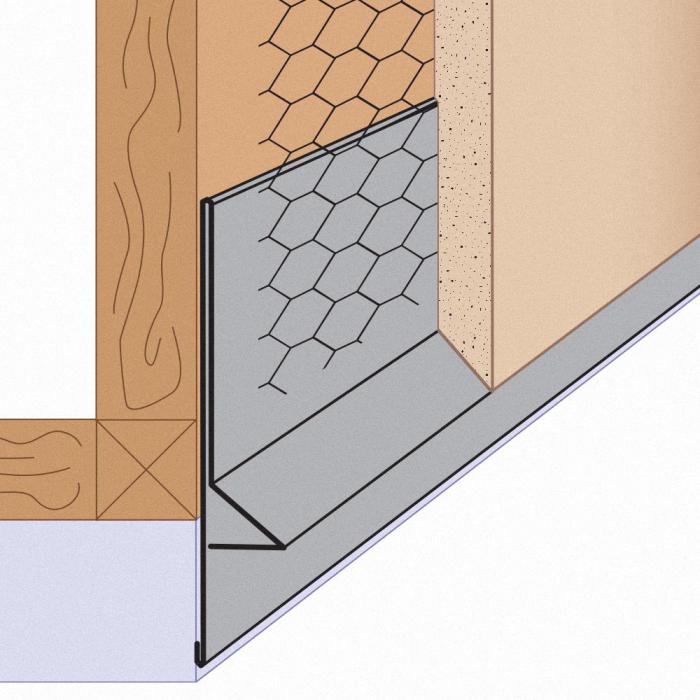

The installation of ebbs is carried out after facing the base, during the external decoration of the facade of the building. Prior to mounting, the upper line of the base or foundation is checked for horizontalness using a level. If there are large distortions, they are leveled with a cement-sand mortar.

Installation

- To ensure a better fit of the tides, slopes are recommended. They are performed as follows: a cord is attached to one of the corners of the wall with a dowel and a self-tapping screw, then it is aligned in level and fixed to another corner of the wall. A cement mortar is prepared , with the help of a trowel, a slope is made on the lace, having an angle of at least 15 degrees. The solution is aged for several days to harden the cement and evaporate excess moisture.

- Ebbs for the basement base can be connected both to the wall itself and to guides installed in advance, to which the facade cladding will subsequently be attached.

- To ensure better water drainage, ebbs are installed with a protrusion beyond the base edge of at least 5 cm. The ebbs are fixed to the guide screws, and to the wall with dowels. The overlap of the strips one on top of the other should be at least 3 cm, and the connection point is best lubricated with frost-resistant sealant. It would also be nice to seal the joints of the ebb and the wall.

- External and internal corners are cut out of the plank sections and fastened in the same way, and the joints are smeared with silicone sealant.

- Wide low tides are attached to the base using brackets, because otherwise they can, so to speak, “walk” from gusts of wind.

The whole installation process takes about 1-3 days, which depends on the amount of work.

Tools and materials required for work

Despite the fact that, at first glance, the ebbs on the foundation are installed quite simply, nevertheless, you still have to purchase a certain set of tools. You will need:

- metal scissors or hacksaw;

- mallet or hammer;

- screwdriver;

- pliers;

- electric drill;

- hammer drill;

- dowels with screws;

- screwdriver.

Performing the correct installation of ebbs for the basement will provide excellent protection against moisture penetration and will extend the life of the foundation for a long time.