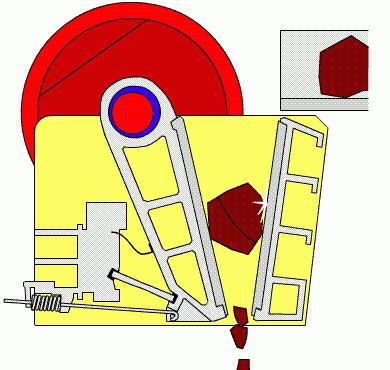

Jaw crushers are the universal and most reliable mechanism for grinding materials. They are used as a tool for crushing slag waste, rocks, and some metal materials. The sizes of pieces of raw materials at the entrance can be up to 1500 millimeters. Small size crushers give the finished product up to 10 millimeters in size. Jaw crushers are divided into small, medium and large crushing classes.

They are actively used for grinding strong rocks, for example, quartz, basalt, granite, as well as materials similar in characteristics to them - concrete, slag, minerals. Such substances as ceramic waste, brick, coal, glass scrap are much easier to grind. Jaw crushers have such basic characteristics as the dimensions of the inlet, the diameter of the outlet slit, as well as the gripping angle. The particle size of the starting substance directly depends on the size of the receiving slit. The gripping angle should be set so that the raw material is not pushed out of the chamber, but succumb to grinding. The size of the outlet adjusts the maximum output parameters of the product.

Jaw crushers are unpretentious and reliable mechanisms that are widely used in the mining industry, in the production of construction and related materials, in the metallurgical industry, in the transport field, as well as in the chemical industry.

This unit has a lot of advantages:

- jaw crushers are quite simple to operate, and also cheap due to their simple design and a minimum of parts subject to rapid wear. Maintenance and repair of this type of equipment is low-cost, while technically not at all complicated;

- the small size allows them to be easily mounted and transported, while they represent the optimal solution for mobile crushing complexes;

- they can be operated in almost all conditions, since they are unpretentious to external factors;

- the discharge gap is controlled by a hydraulic drive, which allows you to quickly and easily adjust it;

- jaw crushers of all sizes and types are equipped with fixed cheeks having an enveloping shape. This protects the bed of the device from premature wear.

This type of device also has disadvantages:

- jaw crushers give the final result, in which there are a large number of flaky grains, which makes their use inconvenient for fine crushing;

- on elastic or viscous materials - polymers, wood, metal alloys - their use is impossible. That is why the wood waste chopper works on a different principle.

Device types

On the market, these crushers are available in several inexpensive and reliable options. The first involves a simple movement of the cheek with respect to the suspension axis. The starting material is crushed by crushing. In the second, the movement of the cheek relative to the suspension is complex. Here, the material is not only crushed, but also abraded when the moving part approaches the fixed part. In the third type, both cheeks make a complex movement relative to the suspension axis.