The reliability and durability of building structures is determined by two factors. The main one can be called the quality of the structure of the material from which the construction is made. But no less significant during operation is the method of installation of individual building components. The formation of ligaments between structures is one of the most important measures, because even with high strength walls, weak points of their connection with ceilings, for example, can lead to deformation of the structure. A classic way to ensure a reliable installation connection in buildings is the anchoring of floor slabs, which is carried out using special hardware, supplemented with reinforcing devices.

General information on structural anchoring

Anchoring is not just for the purpose of forming a bundle between the individual structural elements. The technical coupling must withstand the loads placed on the slabs during the operation of the house. In this case, the pressure may be different depending on the installation location and the type of overlap used. For example, anchoring floor slabs in load-bearing walls involves the addition of additional reinforcing components. Strength in this case is the main technological requirement. But not only physical activity is a threat to such structures.

Since anchor clips are metal products, there is always a risk of the spread of rusting processes. This applies to facilities that use metal fittings. The use of fiberglass rods helps to eliminate the likelihood of corrosion, although in this case the cost of work also increases. In addition, the anchoring of floor slabs should prevent geometric disturbances in the structure. As the norms of SNiP are noted, only flat panels without chips and other areas with deformations can be used for such work.

Design of anchor joints

The purpose of developing a design solution for anchor joints is to implement the optimal layout of fasteners in a building structure. At the exit, rigid fixing belts should be formed, thanks to which a common spatial frame of the house will be formed. In the supporting nodes of prefabricated ceilings on brick walls, anchor elements are installed to prevent shifts of monolithic panels. To achieve this, it is necessary to initially develop a design solution that includes schemes for which the anchoring of floor slabs will be performed. In the drawing, the architect denotes fixation points, guided by calculations of loads. Factors such as foundation deformation, subsidence, tectonic displacements, etc. are also taken into account. Much depends on the particular region in which the building is planned to be built. But, of course, first of all, the parameters of the main structures are taken into account, for example, the nature of the support of the plates on the inner part of the external wall. That is, the emphasis in the overlap is one of the main indicators on the basis of which the mounting configurations of the anchor connection are selected.

Preparing for installation operations

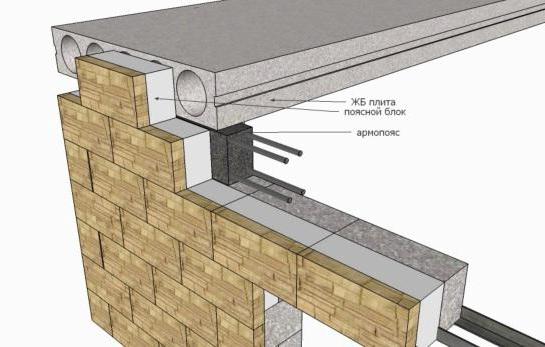

Work begins with ceilings at the moment when the masons complete the forcing of the last rows of masonry. Overlapping should subsequently be laid evenly and without deviations, therefore, it is necessary to create all the conditions for their correct location. The main prerequisite for this will be the formation of a horizontal surface from the base masonry, which will be completed by the time the plates are installed. In practice, the exclusion of future differences is achieved through the use of marks fixed by the horizontal level. If it is planned to anchor floor slabs that will be laid on a load-bearing brick base with a thickness of one and a half blocks, it is advisable to secure the upper row of the partition with reinforcement. It can be a concrete belt 15 cm thick. It is created either by pouring the solution using formwork or by means of special blocks with a U-shape.

Tile laying

At this stage, at least two people are involved in the work. They provide the correct setting of the slab in the place of future installation. However, for greater accuracy and convenience of the working process, it is desirable to connect a third worker, who will either hook the panel or give commands to the crane operator. Installation begins from the wall - the overlap should lie on the layer of the applied solution with a 2-cm thickness. So that the mixture is not squeezed out under the influence of the considerable weight of the plate, it should be made as thick as possible. The accuracy of the fit of the structure also depends on how smoothly the final brickwork was performed, but even in case of deviations during the first approach to laying, the panel can be adjusted in place using crowbars.

Anchor Insertion Technique

Classic rod anchors are made in the form of bent fasteners made of reinforcing steel. In diameter, such elements have an average of 8 to 12 mm. Directly anchoring the floor slabs is performed above the structural opening through a special niche. A hole with a diameter of 50 mm is initially formed for installation. Through the created hole, the empty space is filled with concrete with reinforcement in the form of a reinforcing bar of 30 mm. In turn, the anchor is installed in the filled base near the edge of the hole. It is important to maintain a slope towards the panel end so that the fastener shank is located at the surface of the plate.

Hollow core anchoring

The anchoring technology in this case corresponds to the general rules, but for obvious reasons in the form of a weakening of the structure due to voids, the requirements for the configuration of the location of fasteners are tightened. In particular, the question is ambiguous regarding the possibility of creating three attachment points, in which two short sides and one long are formed. In hollow structures, anchoring of floor slabs and coatings of this type is allowed, but with certain limitations. So, it is impossible to allow that the anchoring was carried out with support panels that wind up on the wall. This operation can only be performed if the overlap rests on two sides. Otherwise, the risk of cracking in the structure increases.

End wall anchoring

The end walls often sin by the processes of movement from the building. It is noteworthy that the current efforts are uncertain. In most cases, walls of this type do not have a connection with ceilings, but regulatory technical documents indicate that elements with a diameter of 10 mm should be used in securing fasteners in such systems. Builders also carry out bricking, thanks to which the standard anchoring of floor slabs is formed. SNiP P-22-81 notes that the gaps from the load-bearing walls should not exceed 6 m. In order to protect the reinforcing elements from corrosion, it is also necessary to install a plaque with a width of at least 30 cm and a thickness of 4 cm.

Fill seams

If it is planned to perform floor slabs with the presence of an expansion of about 50 mm, then it is necessary to perform a separate filling of the joints with mortar. To create a mixture, it is advisable to use concrete grade B15. At the same time, it is not necessary to install reinforcing bars, since the reliability of the solution in a narrow niche should be sufficient to ensure sufficient ability of the structure to cope with the loads. However, when the anchoring of floor slabs in brick buildings is carried out with preservation of joints of about 100 mm, a special frame with lower working rods is also provided. Further, as the distance between the tiles increases, additional frames are added to strengthen the installation system.

Creating communication holes

Technologically, the anchoring allows the preservation of holes for the further passage of communication routes, for example, for wiring. But these configurations are not always possible to mount the reinforcing cage. In such cases, it is recommended to ensure the transfer of forces from the seam area to adjacent plates. Thus, two tasks are solved - the opportunity to skip the communication line is preserved and the load on the tile joint is redistributed. Actually, if for one reason or another it is not possible to include a reinforcing cage into the system in the usual connection configuration, then anchoring the floor slabs without eyes also allows you to transfer additional force to adjacent panels. In such cases, a bent rod with a diameter of at least 12 mm acts as an active element that replaces the frame reinforcement.

Conclusion

Provided that the initial configuration of the location of the connection nodes is correctly calculated, there will be no problems with the future operation of the building. The installation process itself is not particularly difficult, but there are non-standard situations due to the use of special materials and types of fasteners. The traditional anchoring of floor slabs in a brick house is carried out according to the general technology with filling holes. At the same time, do not ignore the additional installation options that this type of connection provides. In particular, the created niche can be used for engineering and technical support of the building, for example, for laying communications.