Individual water supply systems often operate with unstable temperature and pressure indicators. Sharp and strong fluctuations in the end can cause breakdowns on individual circuits and nodes of the pipeline. To exclude such situations, a hydroarrow helps. It not only softens the work of the engineering network, but also performs additional functions, including filtering. What is a hydraulic arrow in a heating system? This is a small plumbing fixture that is built into the network at the initial installation stage or as part of regular maintenance activities.

Device purpose

To understand the essence of the tasks that a hydroarrow (hydraulic separator) solves, one should deal with the nuances of the operation of independent heating systems. That is, communications operating on their own source of heating the water coolant. In home systems, the basis of the heating infrastructure can be formed by boilers, boilers, water heaters, and so on. So, why do we need a hydro arrow in heating systems of this type? The need to use a temperature and pressure stabilizer arises due to the uneven distribution of the load across all system circuits. Unevenness due to the complexity of the pipeline, burdened and consuming equipment. At least in any water heating complex there is a shut-off valve, as well as the simplest means of controlling and regulating flows. To these devices are added target devices for the emission of thermal energy - radiators, convectors, standard batteries, etc. But this is not all. To ensure the circulation of the coolant, pumping groups and collectors are introduced into the network. Circulation pumps, coupled with boiler equipment in an overloaded infrastructure, may not always provide uniform pressure and temperature support. Hence the need for additional regulators and stabilizers.

There is an opinion that a water gun is required only to prevent thermal overload in systems where pumps of different capacities are used. They work from one heating source and, due to the difference in characteristics, are not able to equally maintain pressure balances. The basic purpose of a water gun in a heating system really comes down to leveling their work, but in practice other positive effects are achieved. These include:

- Cleaning contours.

- Optimize system performance.

- Prevention of risks of the occurrence of the return flow of the coolant.

Water Gun Design

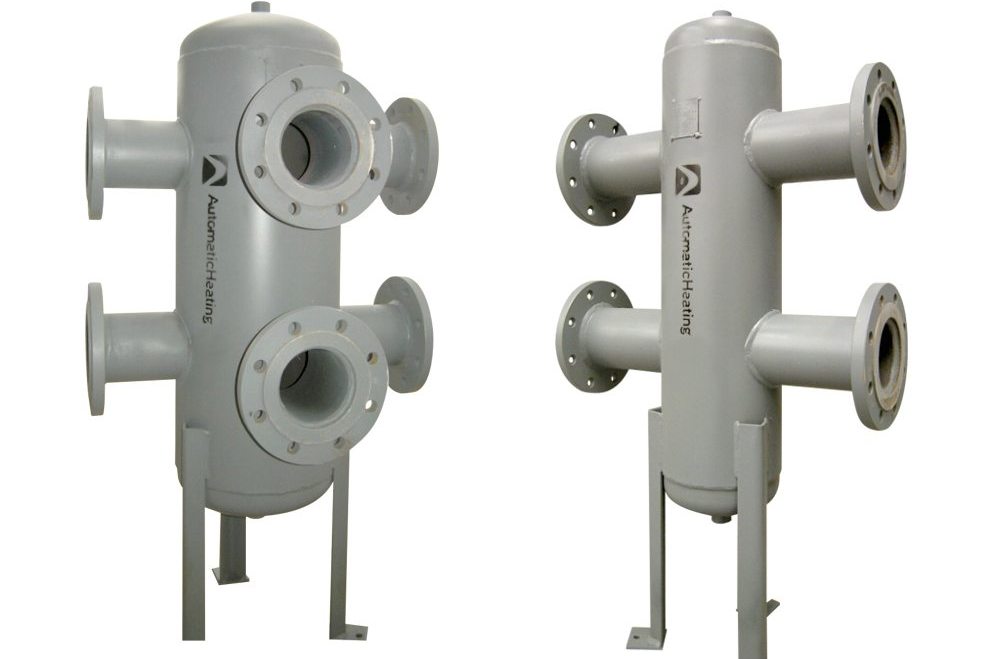

The hydraulic divider looks like an optimized manifold with input and output channels of different diameters. Its fundamental difference can be called the presence of developed means of monitoring and measuring the parameters of the coolant. What is a hydraulic arrow in a heating system in terms of a functional device? This is a design that includes the following components:

- Outlet ball valve.

- Manual air vent.

- Plug for magnetic pickup sensor.

- Sleeve for installing a temperature sensor.

The design also includes removable insulation, pipes for connecting circuits, shut-off valves and, in some versions, a small tank like a hydraulic tank. The function of the latter is usually shifted to the thickened part of the separator tube, which may look like a vessel. As for the materials of manufacture, stainless steel alloys are usually used for the body of the hydraulic arrow. Polypropylene devices are also used, but due to high temperature loads, their use is limited.

The principle of operation of the hydraulic arrow in the heating system

The main task of the hydraulic separator is to separate the boiler circuit from the working branches of the coolant distribution. The device provides pressure equalization between the collector groups, providing the movement of flows at the feed and return. Otherwise, conditions are created for mixing the flows of cold and hot water, which reduces the thermal power in the circuits. How is the regulation process implemented? The principle of operation of the hydraulic arrow in the heating system is to create a buffer zone with zero resistance in the intermediate sections where pressure drops are possible. This ensures pressure relief on all circuits between the pumps.

The need for a natural connection of the function of the hydraulic arrow occurs in the following situations:

- The flow of hot water from the boiler is weaker in strength than the flow path of the coolant on the heating circuits.

- The flow of cold water from the heating circuit is weaker than the flow from the boiler.

In normal operation, if the equipment is selected correctly, the separator buffer is completely depleted to a minimum. How does a hydraulic arrow work in a heating system if there is a violation of the balance of movement of the coolant? Volumes that exceed the norm on the balance from the supply or return side go into the hydraulic tank or the thickened part of the pipe of the hydraulic arrow. Theoretically, situations are also possible when the water of one of the circuits enters the opposite line of movement, bypassing the buffer zone. This indicates an excessive mismatch between the boiler and pump capacities, which requires replacement of units.

The nuances of the operation of the hydraulic arm in systems with a pumping group

In order to increase the efficiency of the heating circuits, the infrastructure can be supplemented by auxiliary pumps and collectors. However, along with the increase in productivity with this approach, we can expect an increase in the load on individual circuits. As a result, a heating system with a hydro-arrow and a pump group can function with the following problems:

- If circulation units with different power ratings are used, then weak pumps will not be able to cope with the loads present on adjacent circuits.

- The division into multiple circuits as a result of the installation of additional functional units also affects the operation of the pump group, which can lead to overloads and failure.

- If the project establishes a regulatory difference in the pressure indicators on individual branches, then the slightest violation in the balancing will cause an accident already in the pipeline.

- With the regular shutdown of individual pumps to stop the water supply at their target site, the risk of movement of “parasitic” currents provoked by neighboring circulating equipment will increase.

The aforementioned operational problems usually arise in complex industrial systems in plants where dozens of consumers are served by a single heat source. In heating systems of a private house, a hydraulic sprinkler usually works in combination with a small pumping group and two to three collectors. Even if we are talking about a two-story house, two pumps can be enough for a full circulation of the coolant. The main thing is to choose them correctly in accordance with the needs of a particular system.

Calculation of a water arrow

The performance of the hydraulic separator is determined by the following set of technical characteristics:

- Operating temperature - from 95 to 110 ° C.

- The serviced boiler power is about 100-125 kW.

- Productivity - average consumption from 4 to 8-9 m 3 / hour.

- The center distance relative to consumers is about 200 mm.

Based on these parameters, a device model is selected for a specific system. How to calculate the heating arrow of a heating system? In addition to the structural conformity (dimensions and dimensions of the nozzles), in order to correctly evaluate the throughput from the point of view of the possibility of balancing the system, the diameter of the buffer zone must be calculated. Experts recommend taking a size that can provide a flow velocity of 0.2 m / s for the optimal cross-section of the separator tank. But this parameter will be directly related to the value of water flow for 1 hour. That is, you must initially determine the throughput of the target circuit or group of circuits. This is the standard value of the boiler, which can be expressed as follows:

- The main heating zone is about 2 m 3 / hour.

- Secondary heating zone - about 1.5 m 3 / h.

- The zone of boiler water heating is 2.5 m 3 / h.

- Low-temperature section for technical needs - 1 m 3 / hour.

The result is a total flow rate of about 7 m 3 / hour. Under this value, a pump group, collectors and a hydraulic arrow are selected. With this throughput indicator, the diameter of the tube vessel of the separator can be approximately 110-120 mm, depending on the design of a particular model.

Installation of a hydraulic arrow

For self-installation, it is desirable to purchase ready-made dividers assembly. In a complete set, the device includes the necessary shutoff valves, an insulating sheath, a degasser and a slurry separator. If necessary, you can additionally purchase fittings and plumbing adapters, but to ensure reliability, it is better to abandon the adapters.

After shutting off the water and turning off the equipment, you can proceed with the installation of the hydraulic gun in the heating system in a horizontal or vertical pattern. The installation process can only be carried out in rooms with a positive temperature. First of all, the device is mounted on the site of operation to the wall with brackets. The position of the separator is thought out in advance, at which it will be possible to connect pipes to its nozzles without additional manipulations. It is very important to keep the connections correct. The inlet feed circuit on one side of the hydraulic arrow must mate with the pipe from the boiler. On the same line from the opposite side, a branch is connected to consumers (heating circuit). Similarly, a return line connection is made.

In the process of installing hydraulics in the heating system with your own hands, it is especially necessary to remember safety measures. Even when the circulation system is turned off, a splash of hot water is not excluded, so it is advisable to work with heat-insulating gloves. After the equipment is installed, pressure testing is carried out, the purpose of which is to check the system for leaks. Then, the first start is carried out using a heat carrier diluted with a propylene mixture with a 40% glycol content.

What is a hydro arrow in a heating system with a condenser?

In systems that provide underfloor heating and radiators, the principle of condensation heat collection has recently been used. Special boilers work on it, provided with a tube for accumulating the energy of the released steam. If in ordinary systems steam is simply discharged into the chimney, then in equipment with a condenser it is collected on the surfaces of the heat exchanger and used in the general heating process. What is a hydraulic arrow in a heating system with this principle of operation? To begin with, it is worth emphasizing that for all condensing boilers with a capacity above 45 kW, the use of pressure and temperature stabilizers is mandatory, since additional energy can affect the performance of the equipment in different ways.

Further, in the process of choosing a model of a hydraulic pump and pumps, two points should be considered. Firstly, the total consumption in the main heating circuit must necessarily exceed that of the boiler line. Secondly, the presence of a separator by default will increase the temperature load on the return circuit entering the boiler. This will reduce productivity and will also require appropriate adjustments for pump power. In general, with negative factors for reducing efficiency, it is precisely the hydro-arrow that will allow balancing the operation of condensation boilers forming a cascade system. For example, if two units are used, then the hydraulic arrow will shift the excess pressure from one to the other.

Additional functionality of the hydraulic arrow

Today, hydraulic dividers with only one balancer function are found less and less. Advanced configuration allows it to be used also for integrated tracking of performance indicators in the system. If the integrated sensors are connected with the boiler automation, the device will provide more precise control of the boiler modes and increase the reliability of fuses. What is the need for a hydraulic gun in the heating system, besides controlling equipment? The presence of a temperature control valve will additionally provide a gradient on the secondary distribution lines of the coolant, and the air vent will create conditions for the release of dissolved oxygen in hot streams of water. But it is important to determine in advance which air exhaust system will be optimal in a particular case - automatic or manual.

Another common function of the hydraulic pump in the heating system is the removal of sludge. For its implementation, a slurry separator is used. Large suspensions and deposits remain in a special drive, and during maintenance are released through the valve. More modern models are optionally equipped with magnetic traps that allow you to remove magnetite.

Is it always necessary to use a hydraulic arrow?

It has already been noted that in some cases the use of this device is mandatory. But this applies only to systems in which non-standard heat exchangers are present or we are talking about complex branched circuits with multitask collectors and pump groups. But why do we need a water gun in a domestic heating system, in which there is only a boiler, boiler and circulation pump? The risks of creating a temperature and hydrodynamic imbalance in such configurations are minimal, and a negative factor of smoothing operating parameters is more likely to reduce equipment performance. But even in such cases, the hydraulic arrow can justify itself as a means of improving the reliability of units and the pipeline as a whole. Even a minimal decrease in pressure drops in the circuits will increase the equipment’s service life - accordingly, its service life will be extended. In other words, the question of the use of a hydraulic arrow for domestic needs can be presented as a choice between economic feasibility and energy efficiency of the heating system.

Conclusion

Hydraulic water supply and heating systems, as technological complexity increases, require the connection of ever new devices and structural additions. This is usually associated with various control and management tools that make the network more ergonomic and functional. In this case, we can talk about security and improving the reliability of system components. Moreover, the integration of the hydraulic separator in itself does not cause much trouble. Do-it-yourself standard installation of the hydraulic arrow in the heating system takes 30-40 minutes, without requiring the use of a special tool. In addition, on the basis of the device in a complete set, you can additionally get an air vent and cleaning agents, which in any case eliminates the need for their third-party installation. In the future, the user will be required to periodically check the integrity of the structure, its tightness and correct operation as part of a general audit of the heating system.