For the technical implementation of fire protection systems, special cable networks based on insulated wiring are used. Communication lines of this type must withstand increased loads in harsh operating conditions, which determines their features. At the same time, wires for fire alarms are available in various versions, which allows direct consumers to individually approach the arrangement of communication networks.

Regulatory Regulatory Documents

In the choice of tools and materials for the organization of fire safety systems, one should first of all proceed from the technical regulations prescribed in document Federal Law No. 123. This Federal Law is of paramount importance as a regulator in the field under consideration. Nevertheless, he describes far from all the technical nuances of the designs of fire safety systems, for which the codes of rules (SP) and GOSTs were separately compiled. For example, GOST R 53315 and SP 5.13130.2009 clearly prescribe the installation and connection of electrical devices. This primarily relates to the selection, laying and connection of wires for fire alarms with the target equipment. Moreover, in the new versions of the documents, the emphasis is on the installation and connection of fire automatics components under the control of programmable modules and controllers. On the other hand, the basic requirements for the protective qualities of wiring have not changed much.

Wire in the design system

Nevertheless, the main task of the cable in the fire fighting complex is to provide energy supply and communication between individual functional devices. Therefore, at a basic level, the characteristics of the route are calculated according to voltage, current frequency, service life, etc. Typical solutions include a wire for a 2x 0.5 fire alarm, that is, a two-core cable with a cross section of 0.5 mm 2 . Such models are able to withstand voltages up to 2 kW with a frequency of 50 Hz, and mean time between failures can reach 5000 hours.

On such wires, routes are placed leading to sensors, detectors, sirens and control equipment responsible for processing signals about signs of fire. Based on the parameters of the room or the building as a whole, individual communication loops and connection points are calculated. As a rule, 10-15% of the length “in reserve” is added to each segment of the connection. In addition, about 10% of the wires for the fire alarm loop in accordance with the regulations should be laid on the implementation of complex sections of the laying. Most often, these are bypass zones of architectural structures, involving a change in the configuration of the gasket, which cannot be calculated in advance.

Brands of wires used

There are several specialized and appropriately labeled cable types on the market that are approved for use in fire alarm systems. These wires include:

- KPS and KPSE - this is the wiring for installing fire protection in different configurations.

- KSHSE and KSHM are specialized solutions for installing fire alarm sensors and mounting alarm loop routes.

- KUNRS is a wire brand for fire alarm, which is used in the power supply circuits of security devices.

- KSB is a family of interface conductors through which the connection of automatic fire systems is realized.

- KSBG - flexible wiring for the organization of alarm systems in the infrastructure of industrial facilities.

Fire Alarm Performance

It is not enough that the wire in the fire protection system meets the working electrical and structural requirements. It is important to take into account the specific conditions of use of such cables, therefore, the degree of its external protection is also a significant factor in the choice of material. First of all, it should be a non-combustible wire. For fire alarms, such products are available in special casings with varying degrees of thermal protection, which will be described below. In addition, such products should be characterized by reduced smoke emission. For example, if we are talking about laying a cable along the evacuation routes, then copious smoke emission will make the evacuation process more difficult. The same applies to toxicity. The same insulation, for example, from polyvinyl chloride, often emits harmful substances, which in facilities where a large number of people work, can cause mass poisoning in fire conditions.

Fire resistant cable concept

Since fire is the main threat in the operation of fire-fighting systems with their components, the fire resistance property deserves special attention. It must be emphasized right away that this is a very specific numerical indicator expressed by the time interval from the beginning of the contact of the cable insulation with the flame to the process of its burning. At least this indicator is 30 minutes, that is, the conditional 10 and 15 minutes in the marking mean that the cable is not fire resistant. The most protected non-combustible wire for a fire alarm has a fire resistance limit of 180 minutes.

Differences between flame retardant cables

It is also necessary to distinguish between fire-resistant wiring and cables that do not support the spread of combustion. In the first case, it is about maintaining the electrical performance of the circuit during the specified time period, and in the second, the material may lose its functions from the very first minutes of the temperature increase, but in the future even with group laying it will not contribute to the spread of the flame in principle.

Types of insulation for fire resistant cable

An increased level of protection against thermal effects is achieved through the use of a special sheath in the structure of the wire. In particular, the following insulators are used:

- The combination of metal and magnesia coatings. The cores are housed in a rigid tube made of stainless steel and filled with magnesium oxide. Such a shell does not emit toxic substances or smoke when in contact with fire.

- Glass-mica coating. A winding based on mica-containing components providing an effective thermal barrier. In order to increase structural protection, additional layers based on polymers and rigid PVC plastics can also be used. Theoretically, laying a wire for a fire alarm of this type is possible in places with a calculated heat load of up to 750 ° C. Under peak thermal conditions, such an insulator maintains its working qualities for 180 minutes. However, during this time, toxic products and smoke may be released, albeit in minimal volumes.

- Ceramic rubber insulator. Also, a kind of polymer coating with the same protective properties as in the case of glass-mica coatings, but with one advantage. Ceramic forming rubber compares favorably with its resistance to various kinds of electrical loads, including voltage fluctuations, short circuits, etc.

Design features

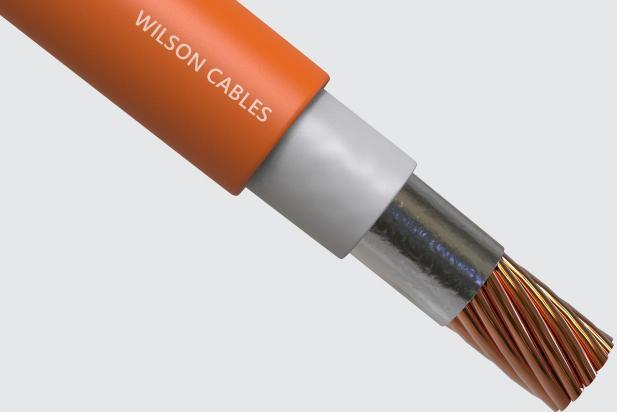

Despite the complexity of the external protective coatings, the internal structure of the wire for the fire protection system is quite simple. The working structure of the cable in most cases is formed by two copper conductors, which are also coated with special insulation. The technique of twisting the cores into bundles is also practiced, which are then placed in aluminum foil, which protects the conductor from electromagnetic interference. Outwardly, a wire for a fire alarm can be recognized by a red or orange sheath. Moreover, it should be borne in mind that such wires can be used equally for direct data transmission systems, and for power supply of fire extinguishing executive bodies.

Fire Alarm Cable Testing

Since we are talking about the use of cables in critical areas, previously conductors with insulators are subjected to special tests. A typical test scheme involves applying a high voltage to the cable when the alarm is turned on. This is the first stage in which the basic function of the wires for a fire alarm is tested without external interference. At the next stage, the place of the conditional laying of the route is heated to critical temperatures of about 700 ° C. From this moment, the compliance of the wire with the declared fire resistance limit is evaluated, that is, is it capable of transmitting data in the time range from 30 to 180 minutes.

Fire resistant cable practice

The fact that the use of specialized fire-resistant wires increases the reliability of the fire safety system, consumers themselves agree. The problem of performing this task during installation is reduced to economic and technical-design factors. The fact is that the need for increased protection of the circuit designed to service the needs of the fire alarm is far from always obvious. Wires for the installation of such systems can be included in common power supply routes with an even higher level of protection, and the presence of its own multi-level fire-resistant sheath, on the contrary, will become an obstacle to such a combination. Therefore, many decide to use simpler, cheaper, but no less effective cables. Formally, this will be a violation of the requirements of the regulation, but from the point of view of practical expediency, a differentiated approach to creating an electrical communications infrastructure most often justifies itself, therefore, a corresponding change in the standards themselves in the near future is not excluded.

Conclusion

The organization of fire protection systems in any case requires the most complete calculation of operating conditions, on the basis of which a project is developed with requirements for communication networks. At a minimum, the designer must determine the optimal electrical characteristics of the wire for the fire alarm, as well as its resistance to possible negative external factors. Moreover, in addition to contact with fire and a rise in temperature as such, it is often necessary to take into account specific threat factors in the framework of various industries. In industrial production, for example, thermal protection can be supplemented by requirements for resistance to chemical and mechanical influences.