How to equip an autonomous water supply system or organize watering from a well in a country house? First of all, it is necessary to choose a pump model. In addition to the function of transporting water, it must be reliable, and its power must correspond to the parameters of the system. For surface mounting, a vortex pump is the best choice.

Application area

The main purpose of any pumping equipment is pumping liquid. To do this, use various mechanisms that differ not only in design, but also in the principle of action. Submersible centrifugal models are not always able to provide the proper pressure level and speed of water transportation.

A surface vortex pump will be the best alternative, as it has a number of operational advantages:

- The compact case combines good performance.

- The self-priming function makes it possible to raise water from a depth of up to 12 m.

- The application of the principle of the formation of a centrifugal flow using an ejector significantly increases the speed of fluid movement.

The vortex pump can be installed at any distance from the place of water intake - just pick up the device with the required power. As an additional equipment , water level sensors, a voltage stabilization unit and an automatic start system can be connected to it.

Since their housing is moisture permeable, often the pumps are installed directly in the house or in a separate building. For temporary use, it is possible to install directly on the ground. But in this case, protection from possible atmospheric precipitation is necessary.

Design and principle of operation

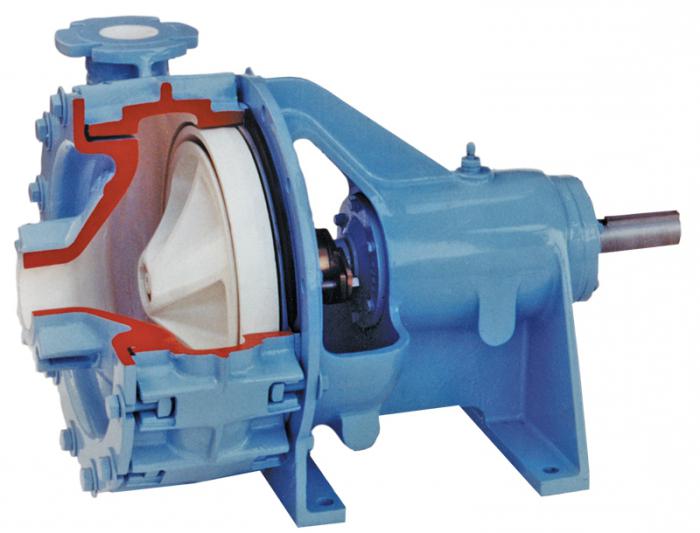

The good performance and technical characteristics possessed by the vortex pump would not have been possible without the specific structure of the device. Structurally, it consists of two main blocks - injection, for pumping water, and an electric motor. The latter is necessary for transmitting torque to a common shaft.

The casing in the pump part has a spiral shape. The blade disc is mounted on an electric motor shaft. When it starts, rotation occurs, as a result of which water fills the chamber. A centrifugal force arises , which creates excess water pressure in the peripheral areas. As a result, the fluid rushes into the outlet pipe. Due to the different distance from the center of the disk to the inside of the casing, the effect of accelerating the movement of water along the pump circuit occurs. As a result of this, the speed of movement and, accordingly, the value of the water column are increased. The vortex pump qb 60, operating according to these principles, is a vivid representative of models of this class.

Self-priming models

A separate category includes devices in which the method of creating an additional air cushion is used to improve performance . For this, the vortex centrifugal pump has a special air valve. During engine start, the blades begin to rotate. Simultaneously with the occurrence of centrifugal force in the rear chamber of the device, a vacuum occurs. Under the influence of external atmospheric pressure, air flows pass through the channels. They provide additional acceleration of the fluid and at the same time create a barrier that prevents water from entering the engine.

Such a vortex centrifugal pump is capable of small dimensions to provide a powerful pressure of water with simultaneous regulation of its quantity. Self-priming models are installed in conjunction with a common system of autonomous cold water for automatic water supply from the well.

Installation and operation

In order for the vortex pump to properly perform its functions, it is necessary to professionally perform its installation. At the first stage, the installation site is selected - it should be optimally located relative to the source of water intake and the end point of its transportation (house, irrigation area). Next, an arrangement is carried out, which includes the following steps:

- Creating a solid foundation. The best option is to install a small reinforced concrete slab or pour a concrete base. This is necessary to comply with the installation level of the pump. Even with a slight deviation, his work may become unstable.

- Protection against external weather factors. Often a canopy is made for this (for temporary installation) or a separate building (permanent location). In the latter case, it is necessary to take care of the heating of the room, since the freezing temperature can lead to freezing of water and damage to the station.

- Stabilization of the input voltage. This will prevent equipment malfunctions. To do this, install a voltage stabilizer.

Upon completion of installation, the tightness of all connections is checked, the compliance of the actual pressure of the water volume with the declared in the pump certificate.

Selection tips

When choosing a specific model, it must be remembered that the vortex pump must perform 2 main functions - to ensure uninterrupted supply of fluid from the well and at the same time have a reliable design.

Many of the models on the market meet these parameters. But in order to choose the best one, it is recommended to adhere to the following recommendations:

- Optimum power indicator and volume of the pumped-over liquid. Depending on the needs, it is necessary to choose such a model that its technical characteristics fully correspond to the required ones - the volume of fluid from the well should not be less than the minimum consumption indicator.

- Head calculation. It depends on the depth of the source of water intake and horizontal pipelines. The manufacturer indicates these data in the equipment passport.

- Warranty for the pump.

Given these factors and applying a planned approach, you can choose the best suitable model of equipment that will fully comply with the requirements of the water supply system.